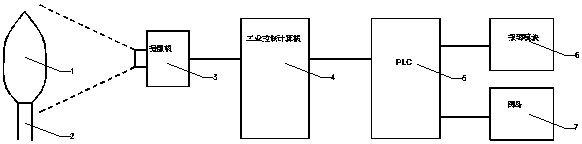

A kind of external vapor deposition method jet flame detection device and method

An external vapor deposition and flame detection device technology, applied to fire alarms, fire alarms, instruments, etc. that rely on radiation effects, can solve the problems of missed alarms, false alarms, etc., and achieve simple structure, strong anti-interference ability, The effect of small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

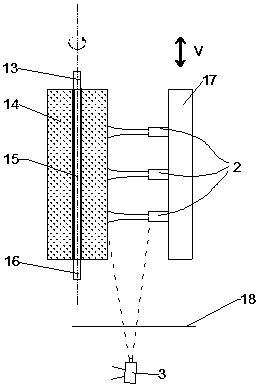

example 1:L100mm, to pic L100mm,,。 example 2

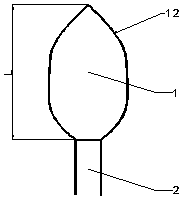

[0021] The working process and detection method of the device of the present invention are as follows: the camera captures the real-time video signal when the blowtorch flame burns, and transmits the flame video signal to the industrial control computer 4 at the same time. After the computer receives the flame video signal, it is analyzed and processed, and the boundary 12 of the flame is described, as figure 2 shown. The computer analyzes and processes the video image of the flame in real time through the image processing module, calculates the length and projected area of the flame, and displays the image and data of the flame in real time on the display screen. Compared with the length threshold, when the collected flame area or length signal exceeds the preset threshold, the computer outputs a control signal to the PLC controller, and adjusts the size of the jet flame through the flame gas control valve, or simultaneously sends a signal to the flame gas control valve an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com