De-excitation and over-voltage protection device for generator rotor

A generator rotor and protection device technology, applied in the direction of emergency protection circuit devices, electrical components, etc., can solve problems such as rotor insulation breakdown, unit equipment damage, etc., achieve fast protection action, fast demagnetization speed, and prevent insulation breakdown The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

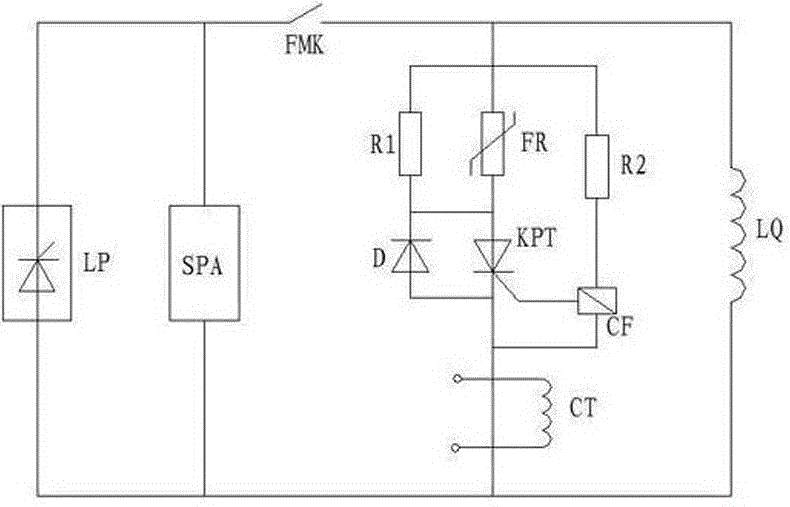

[0008] see figure 1 , a generator rotor de-excitation and overvoltage protection device, which includes de-excitation switch FMK, peak overvoltage absorber SPA, non-linear resistance FR, controllable silicon trigger CF, thyristor KPT, diode D, current mutual inductance CT, linear resistors R1 and R2, one end of the demagnetization switch FMK is connected to one end of the peak overvoltage absorber SPA and then connected to a rectifier power supply, and the other end is respectively connected to one end of the linear resistor R1, one end of the linear resistor R2 and one end of the non-linear resistor FR The other end of the linear resistor R1 is connected in parallel with the other end of the non-linear resistor FR, and then one end of the diode D and one end of the thyristor KPT are connected. another side. The other end of the diode D is connected to one end of the current transformer CT, and the other end of the current transformer CT is connected to the other end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com