Extraction method of filament potting compound for cathode

A perfusion and filament technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problem of reducing the quality of filament component potting, reducing the insulation performance of insulating powder, changing the potting and sintering temperature, etc. problem, to achieve good internal and external consistency, avoid short circuit or open circuit, and the effect of suitable melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

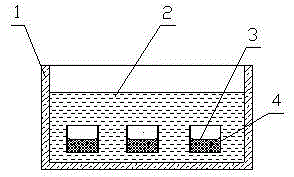

[0023] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0024] The invention relates to a method for taking out filament perfusion for cathode, comprising the following steps:

[0025] 1) Prepare pickling solution 2, wherein the formula in pickling solution 2 is: 25 g / L sulfuric acid and 50 g / L nitric acid. Pour a certain amount of 500ml of distilled water into the 1L beaker 1, slowly pour the calculated sulfuric acid into it, and stir at the same time, measure out the calculated nitric acid, and add it to the solution while stirring carefully to cool the resulting solution to room temperature.

[0026] 2) Prepare an alkaline solution, wherein the formula in the alkaline solution is: ammonia water 60 g / L. Pour a certain amount of 500ml of distille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com