Preparation method of light-emitting device

A technology for light-emitting devices and pixel-defining layers, which is applied in the manufacturing of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problem that the pixel-defining layer is difficult to meet the requirements of the preparation process of full-color light-emitting devices, and achieve easy pixel uniformity. , The effect of preventing electrode short circuit and avoiding open circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

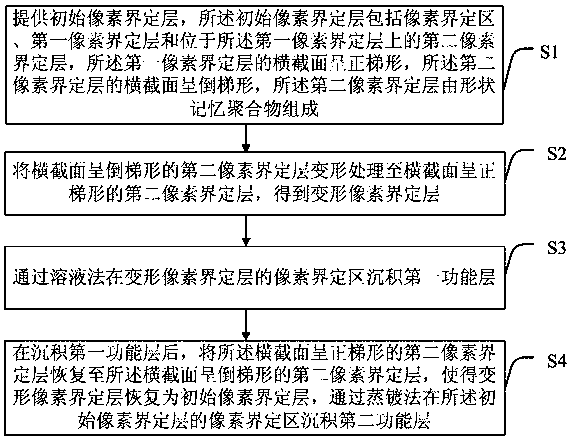

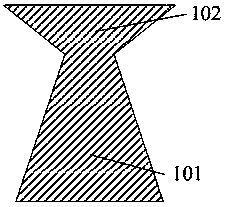

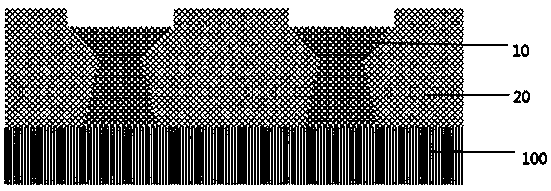

[0085] Add bisphenol A cyanate to the flask, heat to 100 degrees Celsius, and after it is completely melted, add polyethylene glycol, where the mass ratio of bisphenol A cyanate to polyethylene glycol is 10:1, stir and mix After being uniform, put it in a vacuum drying oven at 100-110 degrees Celsius and bake for 0.5-1 h, and then pour the mixture into the hourglass-shaped first mold 20 placed on the substrate 100, such as image 3 As shown, heating at 120-130 degrees Celsius for 2 to 3 hours for curing, and then heating at 210-230 degrees Celsius for 5 hours for post-curing. The hourglass-shaped first mold is removed to obtain an initial pixel defining layer with shape memory. Its glass The transformation temperature is 260~270 degrees Celsius;

[0086] The initial pixel delimiting layer is heated to a temperature T of 280~300 degrees Celsius, and the second mold 30 is used to maintain a uniform pressure F to make the initial pixel delimiting layer reach a preset deformation amou...

Embodiment 2

[0089] Preheat epoxy resin E-51 and methyl tetrahydrophthalic anhydride to 60 degrees Celsius respectively, mix and stir evenly, add 2-ethyl-4-methylimidazole, epoxy resin E-51, methyl The mass ratio of tetrahydrophthalic anhydride and 2-ethyl-4-methylimidazole is 100:60:1. After mixing and stirring evenly, put the resin system in an oven at 80 degrees Celsius and let it stand still, until the bubbles are removed ; Then the mixture is poured into the first hourglass mold 20 placed on the substrate 100, such as image 3 , And then heat at 80-90 degrees Celsius for 2 to 3 hours, 100 degrees Celsius for 2 hours, and 150 degrees Celsius for 2 hours, and then remove the first mold to obtain the initial pixel defining layer with a glass transition temperature of 70 to 90 degrees Celsius;

[0090] The initial pixel defining layer is heated to a temperature T of 100~120 degrees Celsius, and the second mold 30 is used to maintain a uniform pressure F to make the initial state shape memory ...

Embodiment 3

[0093] Mix polyethylene adipate glycol ester glycol (PEA), 1,4-butanediol (BD) and diphenylamine (DPA) according to the mass ratio of PEA, BD, and DPA to 5:4:3 and then heat to 100 ~120 degrees Celsius, dehydrated under vacuum until the water content is less than 0.02%; then under room temperature nitrogen environment, add a metered amount of 4,4-diphenylmethane diisocyanate (MDI), the mass ratio of MDI to the previously added BD is 2: Add the amount of 1, and then quickly stir evenly, and then pour the mixed mixture into the hourglass-shaped first mold 20 placed on the substrate 100, such as image 3 , Cured at room temperature for 3 hours, put it in an oven for curing at 80 degrees Celsius for 24 hours, after removing the hourglass mold, the initial pixel defining layer in the initial state is obtained, and the glass transition temperature is 60 to 70 degrees Celsius;

[0094] The initial state of the pixel defining layer is heated to a temperature T of 80 to 100 degrees Celsius...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com