Twelve-phase permanent magnet propulsion converter

A frequency converter, 12-phase technology, applied in the field of 1.8MW/12-phase permanent magnet propulsion frequency converter, can solve problems such as weak engineering development, achieve good electromagnetic compatibility performance, less optical fiber lines, and good maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

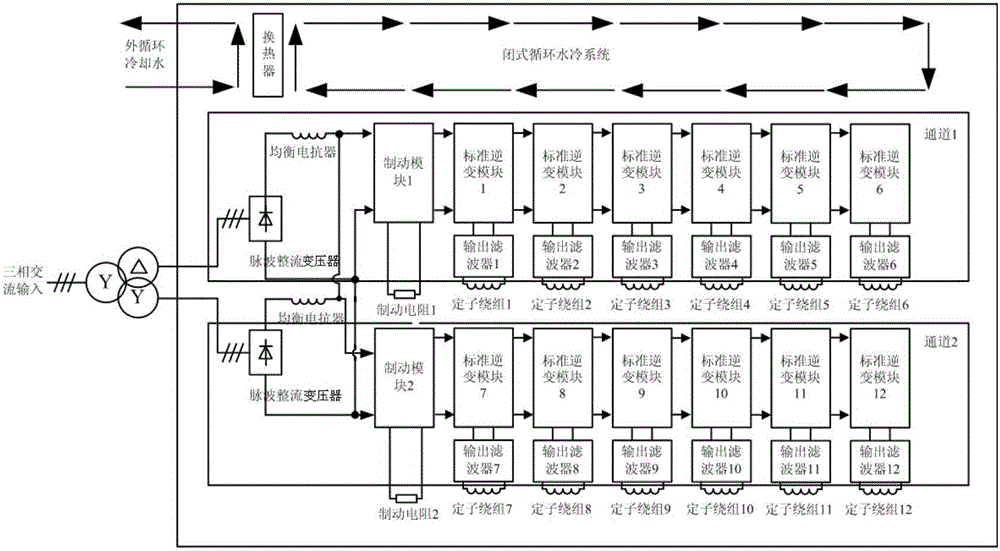

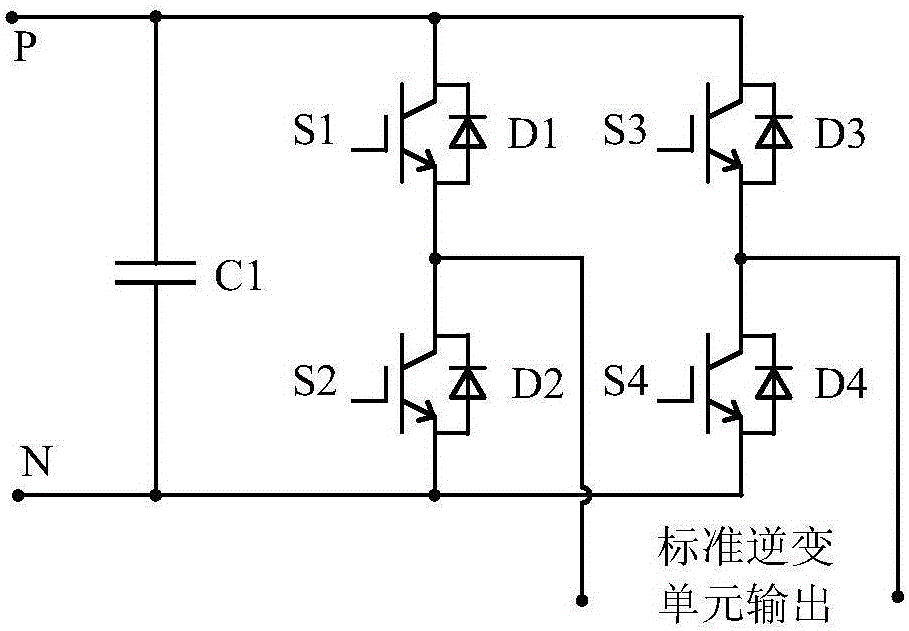

[0019] Such as figure 1 As shown, the present invention provides a 1.8MW / twelve-phase permanent magnet propulsion frequency converter, which is characterized by: 12 identical standard inverter modules, 12 identical filters, 2 identical standard braking modules, The 12 standard inverter modules and 2 standard braking modules are evenly distributed in the two channels; the three-phase AC input passes through the rectifier transformer and the equalizing reactor to output the DC voltage to the common DC bus bar in the two channels; The standard inverter modules and standard braking modules in each channel are connected in parallel to the common DC bus; the output of each standard inverter module is connected to the input of one filter; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com