Airflow-stabilizing air knife of high-speed tin coating machine

A technology of tin coating machine and air knife, applied in coating, metal material coating process, hot-dip plating process, etc., can solve the problem of excessive wind resistance of air knife, uneven wind speed of air outlet flow field, poor stability effect, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

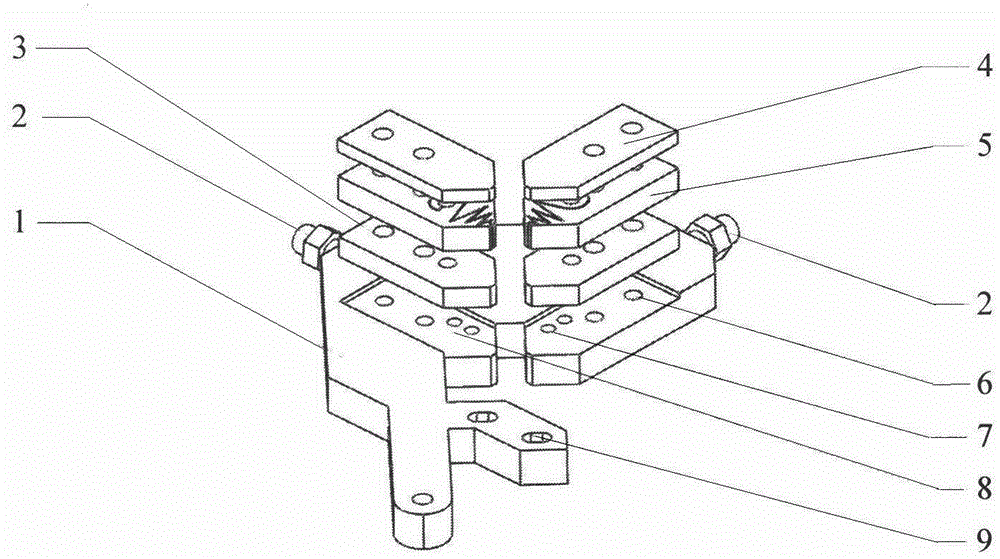

[0022] Such as figure 1 , The air knife device in the embodiment of the present invention mainly includes a knife body base (1), an air knife connecting plate (3), an air knife main board (5), an air knife cover plate (4) and other bolted parts. The bottom plate of the knife body (1) mainly plays the role of installation and fixing. When the device is applied to the tin coating device, the air knife device is installed above the molten tin pool of the tin coating system through the installation and fixing hole (8) of the knife body base (1). Input through the air inlet joint (2) on the blade base (1), there is also an air flow path inside the base for air transmission and guidance; the air knife connecting plate (3) is close to the groove (8) of the blade base (1) Installatio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap