Integral water-stopping lantern ring for concrete pipeline joints

A concrete, integral technology, applied in the direction of pipes/pipe joints/pipe fittings, through components, mechanical equipment, etc., can solve the problems of reducing construction efficiency, increasing production costs, increasing construction costs, etc., to reduce construction costs and solve water leakage. problems, the effect of ensuring the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

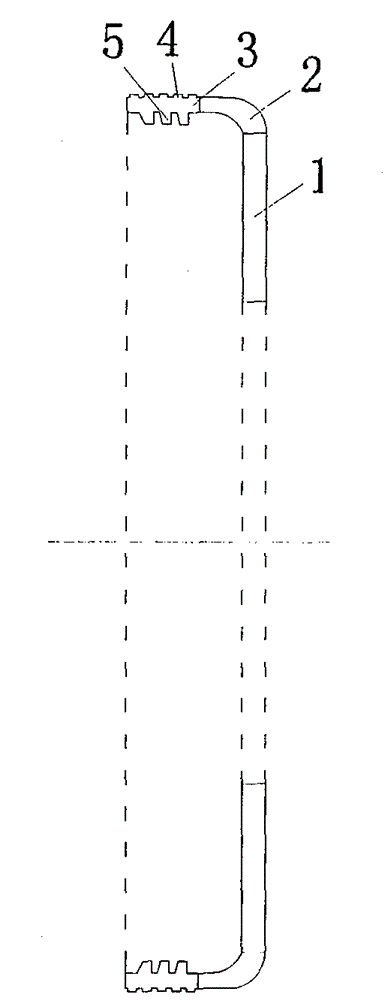

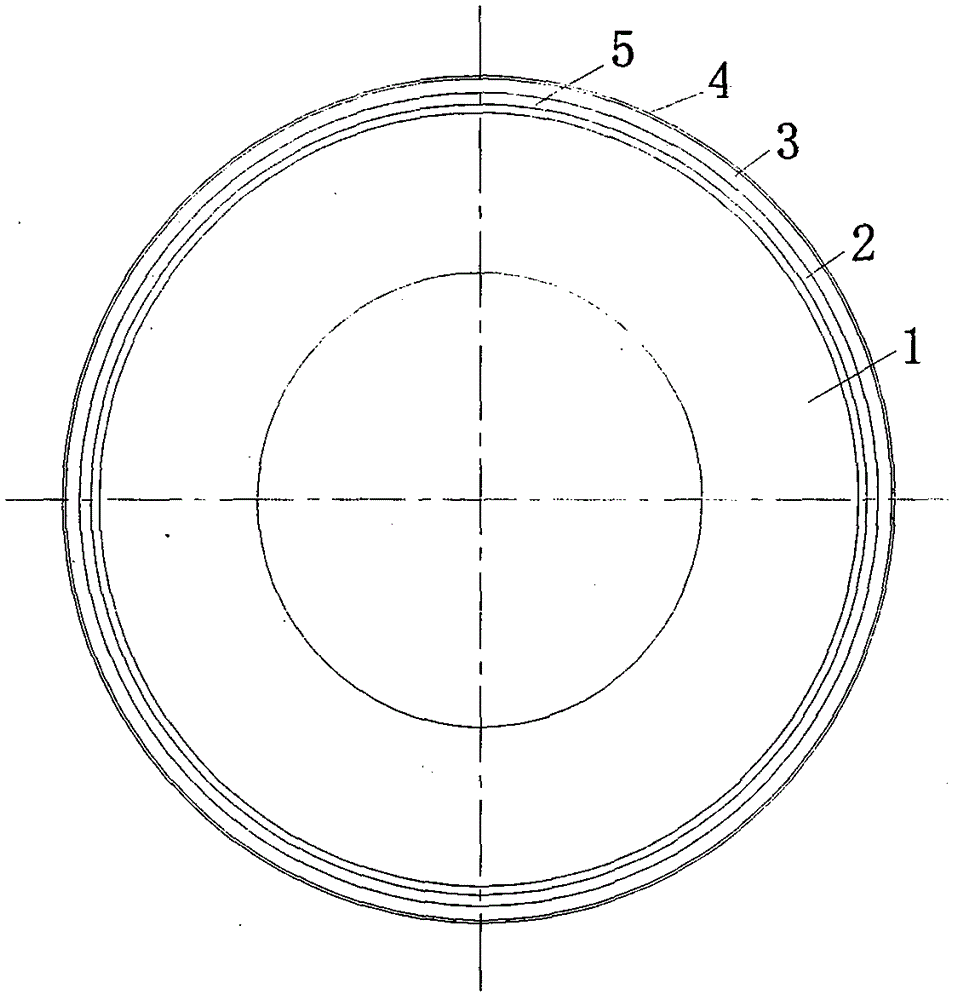

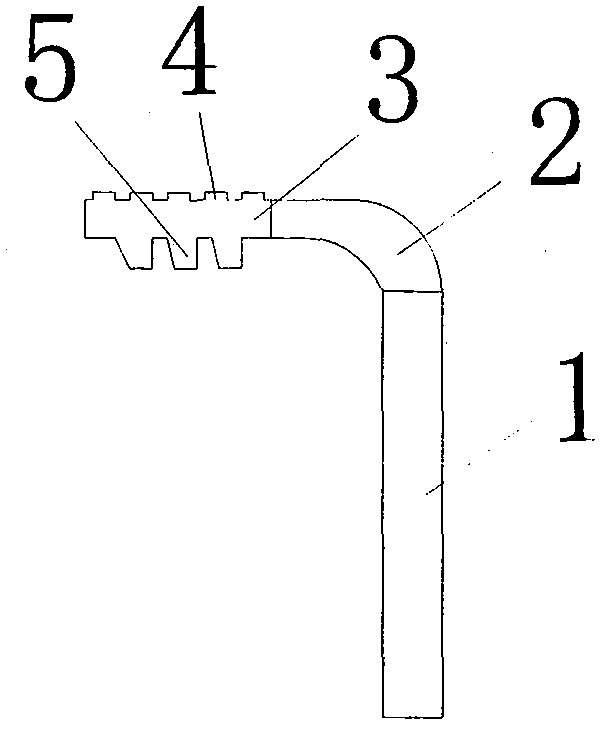

[0017] The invention is an integral water-blocking collar for the interface of a concrete drainage pipe, comprising a buffer plate, a connecting ring, and a water-blocking ring, and the connecting ring integrally connects the buffer plate and the water-blocking ring. Compression teeth are arranged on the inner side and the outer side of the water blocking collar.

[0018] During implementation, the integral water-blocking collar is installed at the port of the concrete pipe joint, and the buffer plate is sandwiched between the end faces of the two concrete pipe joints; the water-blocking collar is set on the outer wall of the concrete pipe joint socket, and the outer side is close to the inner wall of the pipe socket; The connecting ring is integrated with the buffer plate and the water blocking ring to form a closed structure. Figure 4 , as shown in Figure 5. The water blocking ring is compressed and the teeth are deformed by extrusion, and the tension generated by the defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com