Exhaust gas sampling apparatus, exhaust gas analysis system and exhaust gas dilution method

A technology of sampling device and dilution flow, which is applied in the direction of sampling device, exhaust device, exhaust treatment device, etc., can solve the problems of large and complex system, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

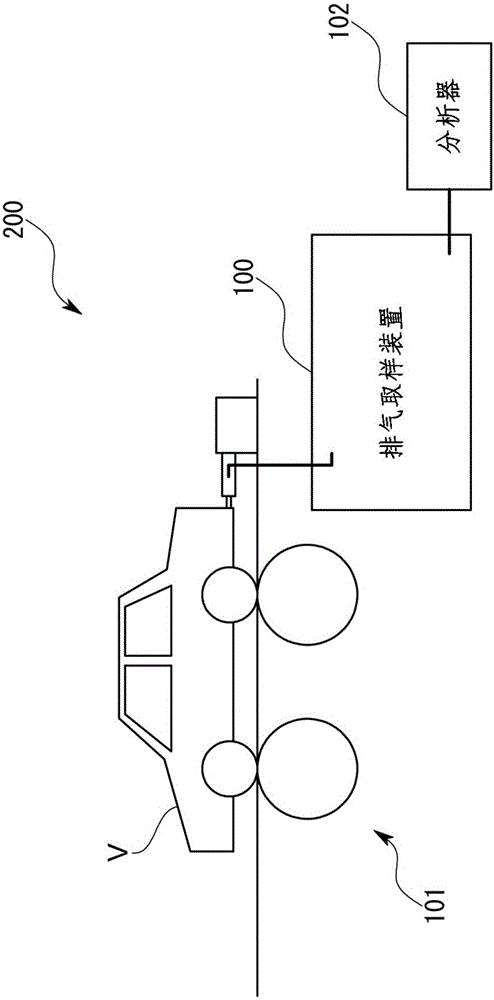

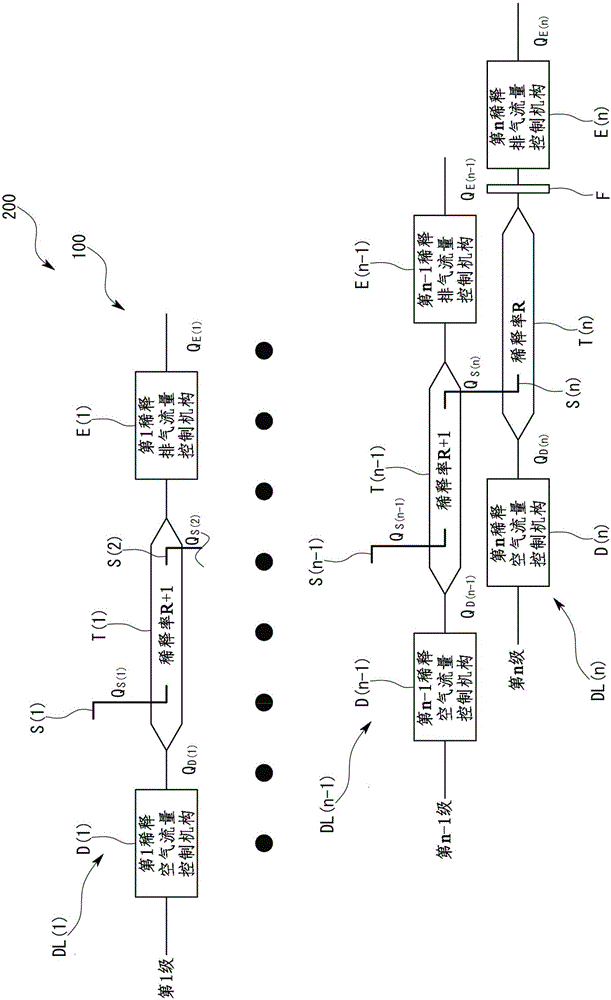

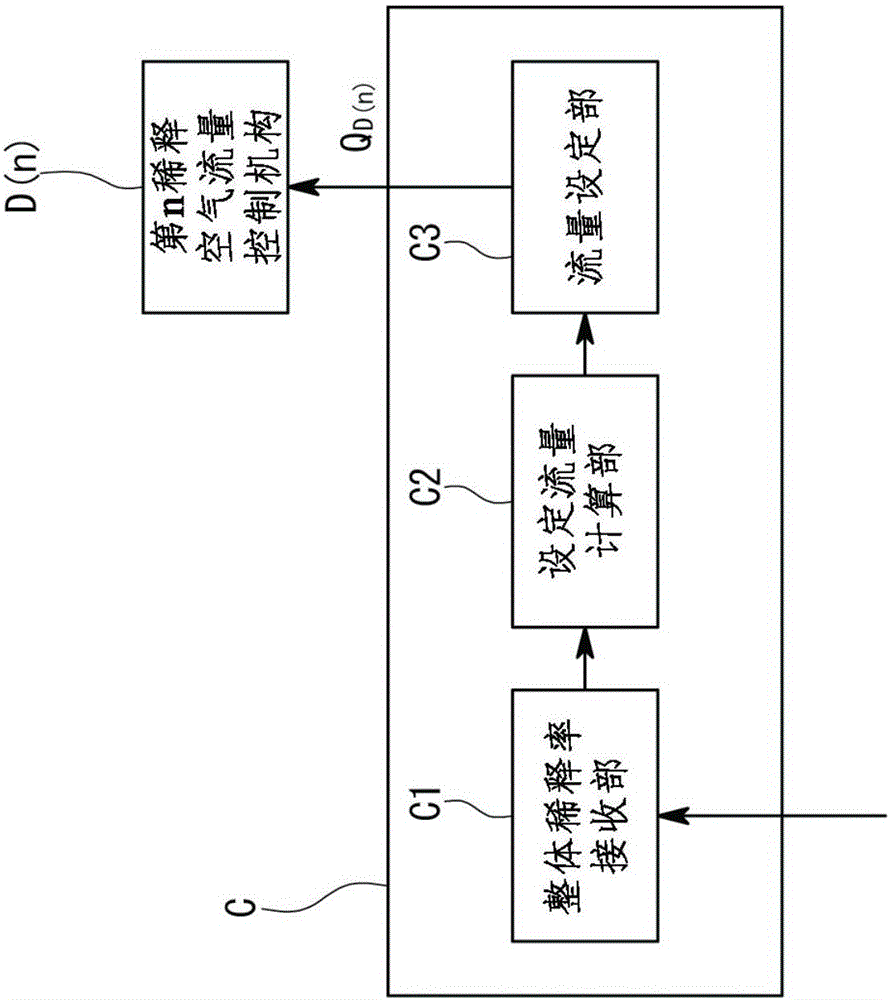

[0048] refer to figure 1 and figure 2 An exhaust gas analysis system 200 and an exhaust gas sampling device 100 according to one embodiment of the present invention will be described.

[0049] Such as figure 1 As shown, the exhaust gas sampling device 100 of this embodiment constitutes a part of an exhaust gas analysis system 200 for measuring the amount of particulate matter (hereinafter also referred to as PM) having a predetermined particle diameter contained in exhaust gas. More specifically, for example, for the installation pipe installed on the exhaust pipe of the vehicle V that is tested on the chassis dynamometer 101, the sampling pipe S of the exhaust gas sampling device 100 is inserted from the side of the installation pipe to the inside. . Then, a part of the original exhaust gas discharged from the vehicle V is sampled by the sampling pipe S, and diluted to a predetermined concentration by the exhaust gas sampling device 100 . The diluted exhaust gas diluted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com