A fully automatic detection system based on microscope

A detection system and fully automatic technology, applied in microscopes, instruments, optics, etc., can solve the problems of inability to realize the automatic movement of the slides to be inspected and the low degree of automation, so as to reduce subjectivity and inexperience, and reduce the labor intensity of personnel , The effect of simplifying the testing procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

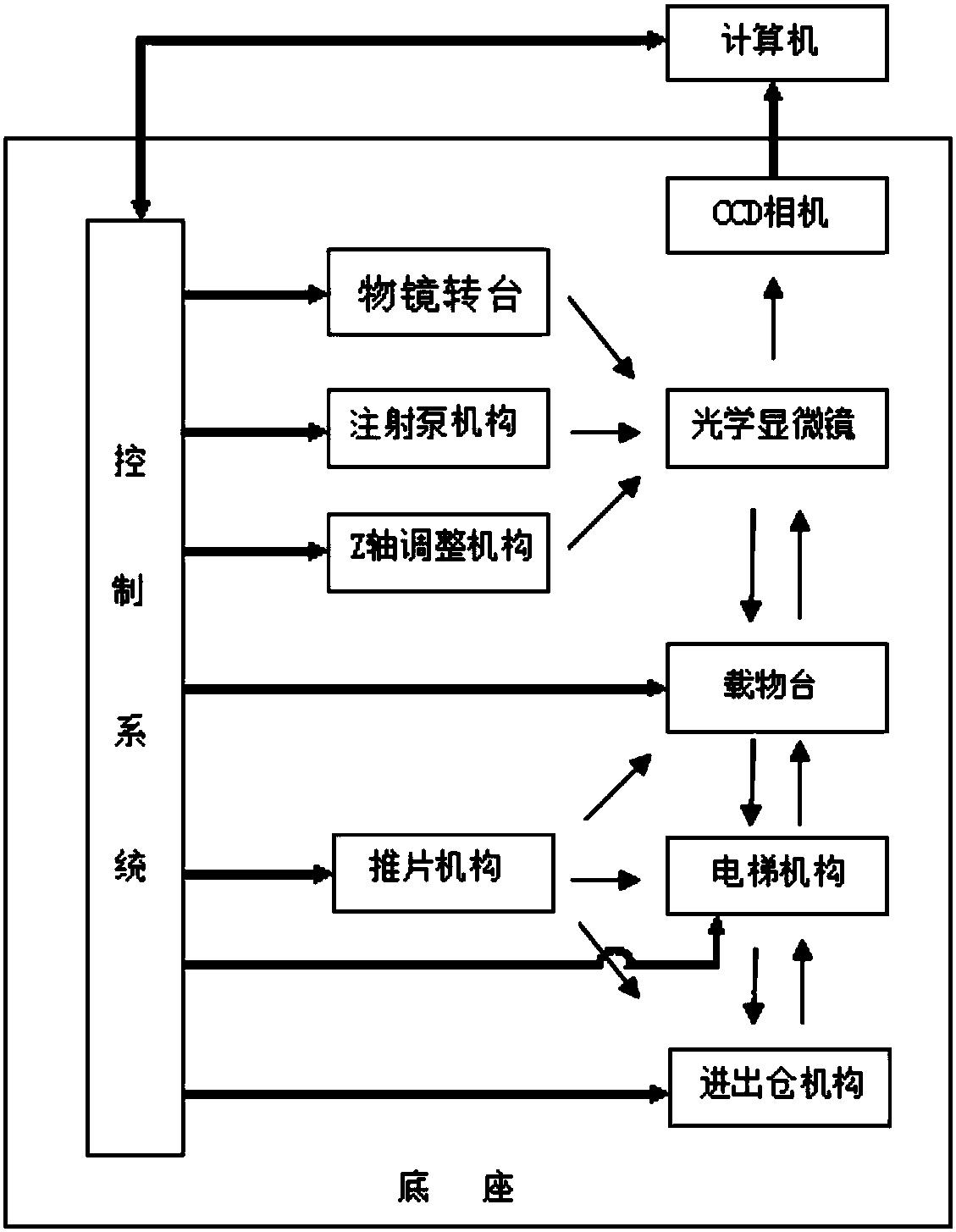

[0021] A fully automatic detection system based on a microscope, its composition is as follows: figure 1 As shown, it includes the mechanical system mounted on the base, the optical microscope and the control system used to control the stepping motors that power the mechanical system. computer for data processing. The mechanical system moves the smear of the inspected object to the optical microscope. The light emitted by the light source of the optical microscope passes through the smear of the inspected object and is focused and imaged on the electronic eyepiece of the CCD camera through the objective lens. The CCD camera converts the imaged optical signal to After the electrical signal is sent to the computer for image processing and detection.

[0022] The mechanical system includes an in-out mechanism installed on the base for moving and placing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com