Preparation method of plateau highland barley water

A highland barley and plateau technology, applied in the field of highland highland barley water preparation, can solve problems such as process parameters of highland barley water that have not been seen, and achieve the effects of improving extract quality, huge market potential, and increasing extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 The preparation method of highland barley water comprises the following steps:

[0030] (1) After mixing highland barley broken to 30 mesh with water at a ratio of 1kg:15L, adjust the pH value to 11 with sodium bicarbonate with a mass concentration of 85% to obtain a mixed solution.

[0031] (2) Add 0.30 g of amylase and 0.350 g of cellulase in sequence to 1000 mL of the mixed liquid, and then perform ultrasonic extraction to obtain an extract.

[0032] Among them: the ultrasonic extraction conditions refer to the temperature at 55°C, the frequency at 35 kHz, and the extraction time at 15 min.

[0033] (3) The pH value of the extract was adjusted to 4.5 with 85% citric acid, placed at 4°C for 10 hours, and then filtered to remove the protein in the solution to obtain a supernatant.

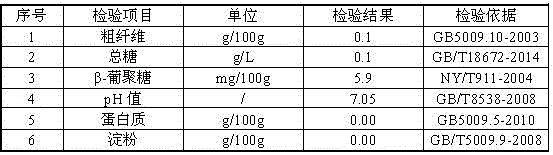

[0034] (4) After performing ultrafiltration on the supernatant, the highland barley extract rich in crude fiber and highland barley β-glucan is obtained by spray drying.

[0...

Embodiment 2

[0041] Embodiment 2 The preparation method of highland barley water comprises the following steps:

[0042] (1) Mix highland barley broken to 80 mesh with water at a ratio of 1kg:25L, and adjust the pH value to 11 with sodium bicarbonate with a mass concentration of 95% to obtain a mixed solution.

[0043] (2) Add 0.50 g of amylase and 0.50 g of cellulase in sequence to 1000 mL of the mixed liquid, and then perform ultrasonic extraction to obtain an extract.

[0044] Among them: the ultrasonic extraction conditions refer to the temperature at 65°C, the frequency at 45 kHz, and the extraction time at 25 min.

[0045] (3) The pH value of the extract was adjusted to 4.5 with 95% citric acid, placed at 4°C for 14 hours, and then filtered to remove the protein in the solution to obtain a supernatant.

[0046] (4) After performing ultrafiltration on the supernatant, the highland barley extract rich in crude fiber and highland barley β-glucan is obtained by spray drying.

[0047] A...

Embodiment 3

[0053] Embodiment 3 The preparation method of highland barley water comprises the following steps:

[0054] (1) After mixing highland barley broken to 40 mesh with water at a ratio of 1kg:20L, adjust the pH value to 11 with sodium bicarbonate with a mass concentration of 90% to obtain a mixed solution.

[0055] (2) Add 0.40 g of amylase and 0.40 g of cellulase in sequence to 1000 mL of the mixed liquid, and then perform ultrasonic extraction to obtain an extract.

[0056]Among them: the ultrasonic extraction conditions refer to the temperature at 60°C, the frequency at 40 kHz, and the extraction time at 20 min.

[0057] (3) The pH value of the extract was adjusted to 4.5 with 90% citric acid, placed at 4°C for 12 hours, and then filtered to remove the protein in the solution to obtain a supernatant.

[0058] (4) After performing ultrafiltration on the supernatant, the highland barley extract rich in crude fiber and highland barley β-glucan is obtained by spray drying.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com