Method for recombining cereal germ components

A germ and grain technology is applied in the field of recombination of grain germ components, which can solve problems such as poor utilization of grain germ, and achieve the effects of not easy to oxidize and corrode, stable performance, and improved utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

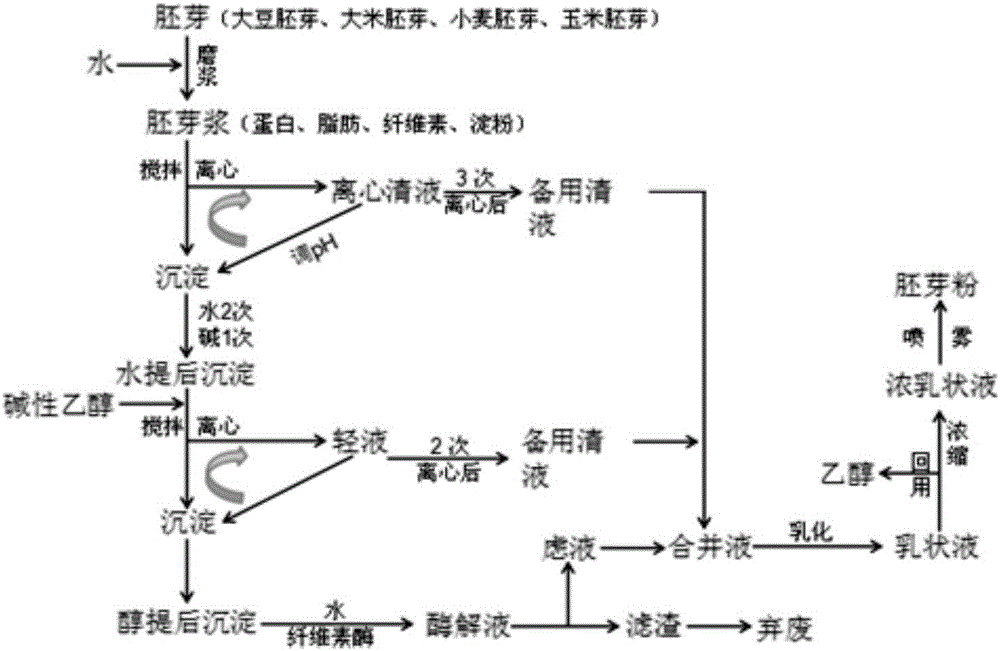

Method used

Image

Examples

Embodiment 1

[0029] A kind of corn germ powder made from corn germ in this embodiment, corn germ is used as feed after oil extraction, and we will add stevioside (dosage 0.03 %), made into fat-free, sugar-free meal replacement products to meet the nutritional needs of bodybuilders.

Embodiment 2

[0031] A kind of soybean germ powder of this embodiment is made with soybean germ as raw material. In soybean processing (soybean oil, soybean milk powder, soybean milk), the general peeling process is to remove soybean germ together, and the enterprise is to mix soybean skin and germ backfill into soybean meal The middle-dang soybean meal is sold or thrown away directly. The difference from Example 1 is that soybean germ contains a large amount of isoflavones and has a strong bitter taste, so it needs to be refined with a small amount of licorice; soybean lecithin and fructose syrup need to be added during emulsification and recombination. During the method, the soybean germ is refined, and after water and alcohol circulation extraction, in every 100 kilograms of soybean germ (dry weight), the addition amount of licorice is 0.3%, soybean lecithin is 0.1%, and fructose syrup is 15%; spray after sterilization and concentration Dried to make a sweet soybean germ powder. It is e...

Embodiment 3

[0033] A kind of composite germ powder of this embodiment is made of corn germ, soybean germ, wheat germ, and rice germ as raw materials, and the ratio of corn germ, soybean germ, rice germ, and wheat germ is 1:1:1:1. The germ powder has more comprehensive active functional components. The compound germ powder can also be added with 0.03% stevioside, 0.5% donkey-hide gelatin powder, and 2% red date powder to make it into a functional health food for middle-aged and old people to invigorate qi and activate blood.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com