Mist convection type mining efficient wet dust collector

A wet dust collector and mine-used technology, applied in chemical instruments and methods, combination devices, separation devices, etc., can solve the problems of low dust reduction efficiency, achieve convenient processing, reasonable and reliable structural design, and enhance the effect of negative pressure capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

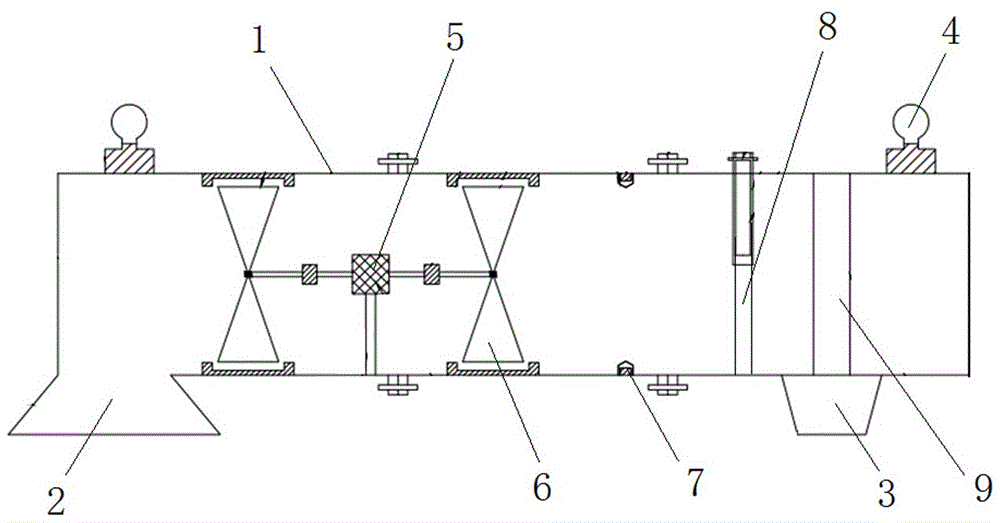

[0012] A wind-mist convection type high-efficiency wet dust collector for mining, including a columnar frame 1, a coal dust suction port 2 is provided at the left lower end of the columnar frame 1, a sewage collection pool 3 is provided at the right lower end of the columnar frame 1, and the columnar frame 1 Hanging lugs 4 are arranged on the left and right sides of the upper end; explosion-proof motor 5 is arranged in the columnar frame 1, fans 6 are arranged on the left and right output shafts of the explosion-proof motor 5, and the inner wall of the columnar frame 1 on the right side of the fan 6 is evenly arranged with The nozzle 7 located on the same plane, the columnar frame 1 on the right side of the nozzle 7 is provided with a filter screen 8, and the columnar frame 1 on the right side of the filter screen 8 is provided with a dehydration cylinder 9 communicated with the sewage collection tank 3.

[0013] The phase difference between the two fans 6 rotates counterclockw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com