Concentration gradient generator capable of generating any linear and secondary curve profile

A quadratic curve, concentration gradient technology, used in laboratory containers, laboratory utensils, chemical instruments and methods, etc., to achieve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

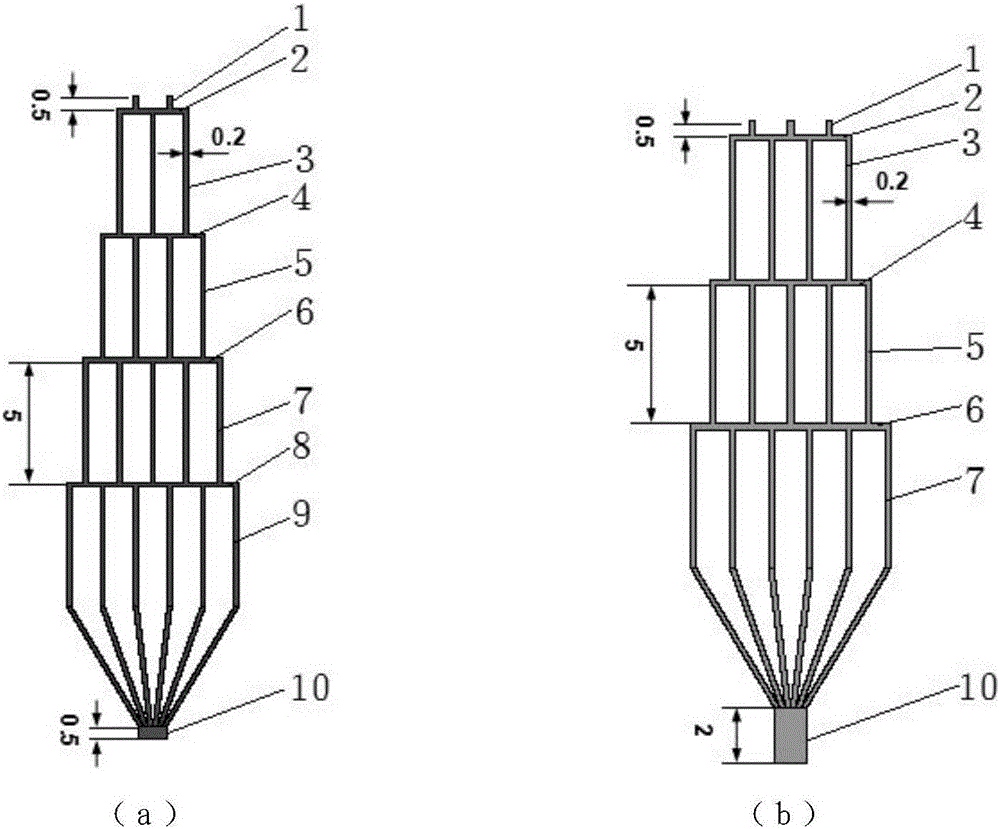

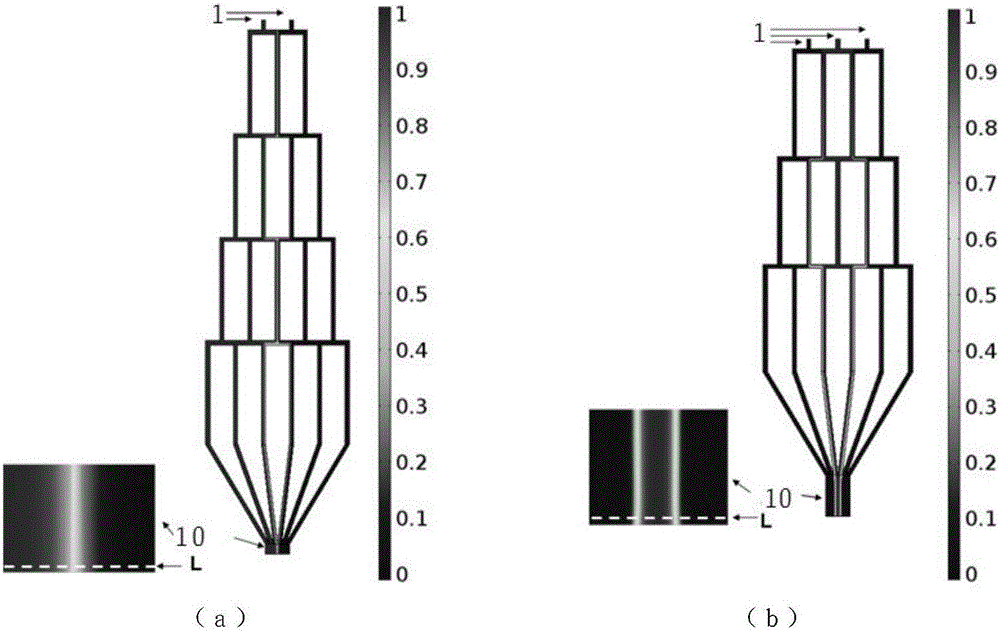

[0019] Such as figure 1 As shown, the present invention provides a concentration gradient generator capable of producing arbitrary linear and quadratic profiles, including 2 or 3 inlet ports 1, such as figure 1As shown in (a), when two inlet ports 1 are included, the two inlet ports 1 communicate with the first transverse channel 2 through the channel wall of the first transverse channel 2, and the first transverse channel 2 and the three The upper ports of the first vertical passages 3 are connected, and the three first vertical passages 3 are distributed at equal intervals in order from left to right, and the first vertical passage 3 at the leftmost end is connected to the first transverse passage 2 The left ends of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com