Garbage zero discharge method

A garbage, zero-discharge technology, applied in the field of solid waste disposal, can solve the problems of pollution damage to the air, water and land environmental quality and human and biological health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

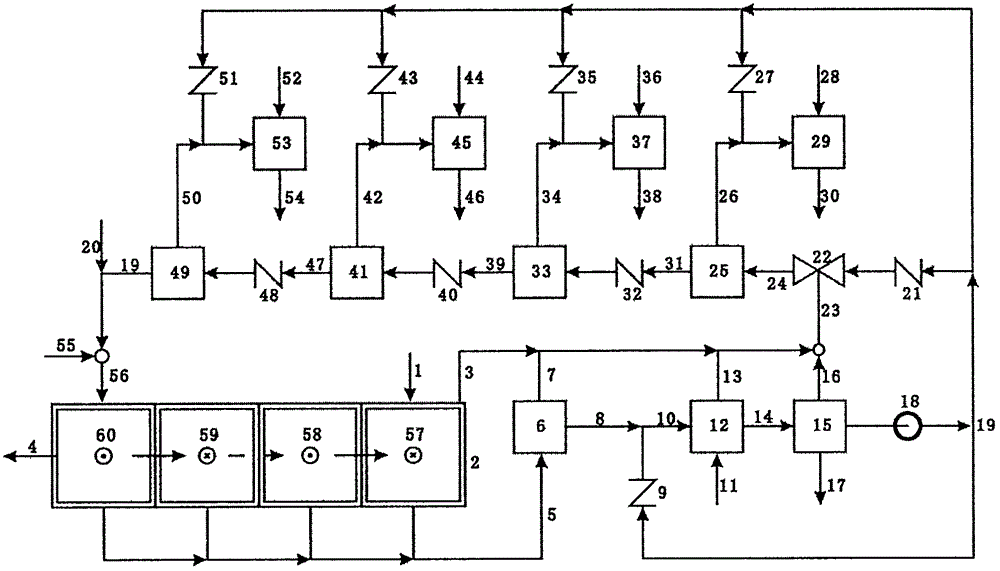

[0022] Garbage waste 1 is rotated in the vertical flow column well of washing channel 2 in this example, from washing 1 column 57 to washing 4 column 60, and convectively leaching with reused purified water 56, and reclaiming anaerobic garbage 3 and The scum and scum collected by the fence include washing waste purification scum and sludge. The bottom of the well outputs the waste solution 5 and its slag, and the closed waste liquid pool 6 liters slag filtering solution is used as the waste exhaust gas 7 and the ammonia nitrogen hydrolyzed Garbage sewage 8, and the circulating sewage 10 and oxidizing air 11 are diluted by circulating purified water 19, and the closed biochemical unit 12 and purification pool 15 are used for biochemical denitrification, decarbonization and phosphorus removal as biochemical exhaust 13, physical and chemical exhaust 16 and The system water source of the recycled purified water can be continuously reused by recycling the sludge 17.

[0023] Press car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com