Automatic five-axis welding manipulator

An automatic welding and manipulator technology, applied in the field of automation, can solve problems such as high operator skill requirements, low equipment utilization, and inability to meet, and achieve the effects of good flexibility, convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

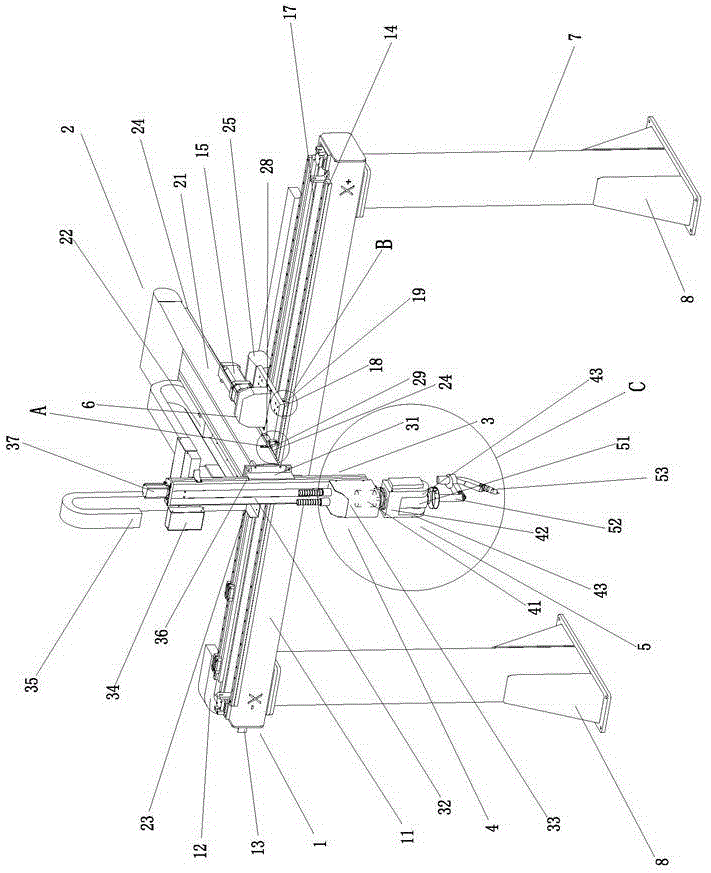

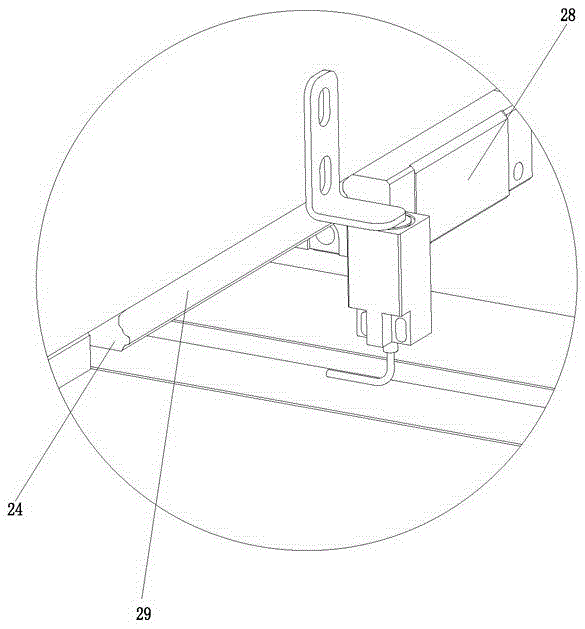

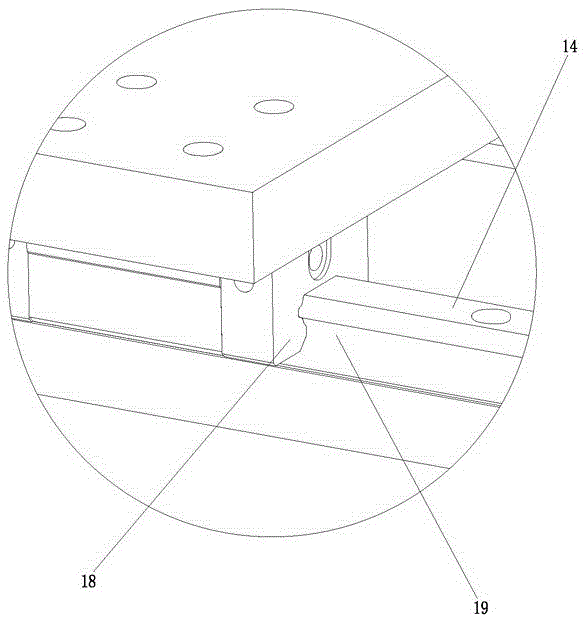

[0031] Such as Figure 1-7 As shown, a five-axis automatic welding manipulator includes a machine base 7, and also includes an X-axis mechanical arm 1 horizontally arranged on the upper end surface of the machine base 7, and also includes a movably arranged on the X-axis mechanical arm 1, and is perpendicular to The Y-axis mechanical arm 2 of the X-axis mechanical arm 1 also includes a Z-axis mechanical arm 3 that is movably arranged at one end of the Y-axis mechanical arm 2 and is vertically arranged, and also includes a movably arranged Z-axis mechanical arm 3 lower end. The end effector 4 also includes a welding device 5 arranged on the end effector 4;

[0032] The X-axis mechanical arm 1 includes a first mounting base 11 arranged on the machine base 7, and also includes a first wiring drag chain 12, and also includes a first wiring drag chain 12 fixed on one side of the first mounting base 11 to facilitate the transmission of the first wiring drag chain 12. A wiring towli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com