Lever type pressurization mechanism of grinder

A pressurizing mechanism and lever-type technology, which is applied in the direction of grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems that the concentricity of the upper and lower axes cannot be guaranteed, and the normal processing state of the machine tool is affected, and the accuracy required by the machine tool is easy to maintain. The effect of long-term maintenance of precision and convenient transportation is required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

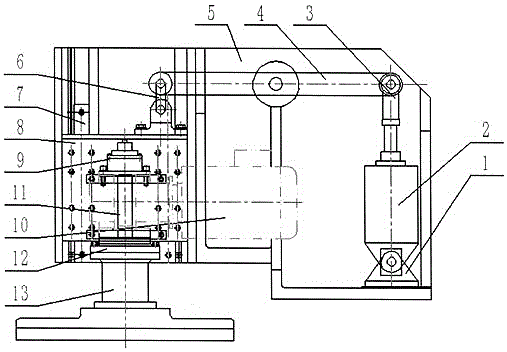

[0009] The embodiment is described in detail in conjunction with the above drawings. The connection structures involved in this technical solution include: connecting sleeve 3, lever 4, rocker arm 5, connecting rod 6, guide rail 7, carriage 8, upper bearing seat 9, upper main shaft 11 and lower Bearing seat 12 constitutes, specific embodiment such as figure 1 As shown, the support 1 is fixed on the rocker arm 5, its upper end is connected to the cylinder 2, the middle part of the lever 4 is connected and fixed on the fulcrum of the rocker arm, and the other end is connected to the connecting sleeve 3. Furthermore, the cylinder is connected to the lever 4 through the connecting sleeve 3 , the fulcrum of the lever is a point on the rocker arm, the other end of the lever is connected with the carriage 8 through the connecting rod 6, the carriage 8 is fixed on the guide rail 7 by bolts, the upper bearing seat 9 is installed on the carriage, and the bearing seat is equipped with Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com