A four-wheel pure electric drive electric vehicle including a final drive and a differential

A main reducer and electric vehicle technology, applied in the direction of electric vehicles, control drives, motors, etc., can solve the problems affecting the battery layout space, low power density and efficiency, and large axial installation size, so as to reduce the center of gravity of the vehicle, The effect of reducing the unsprung mass and reducing the space occupied by the chassis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

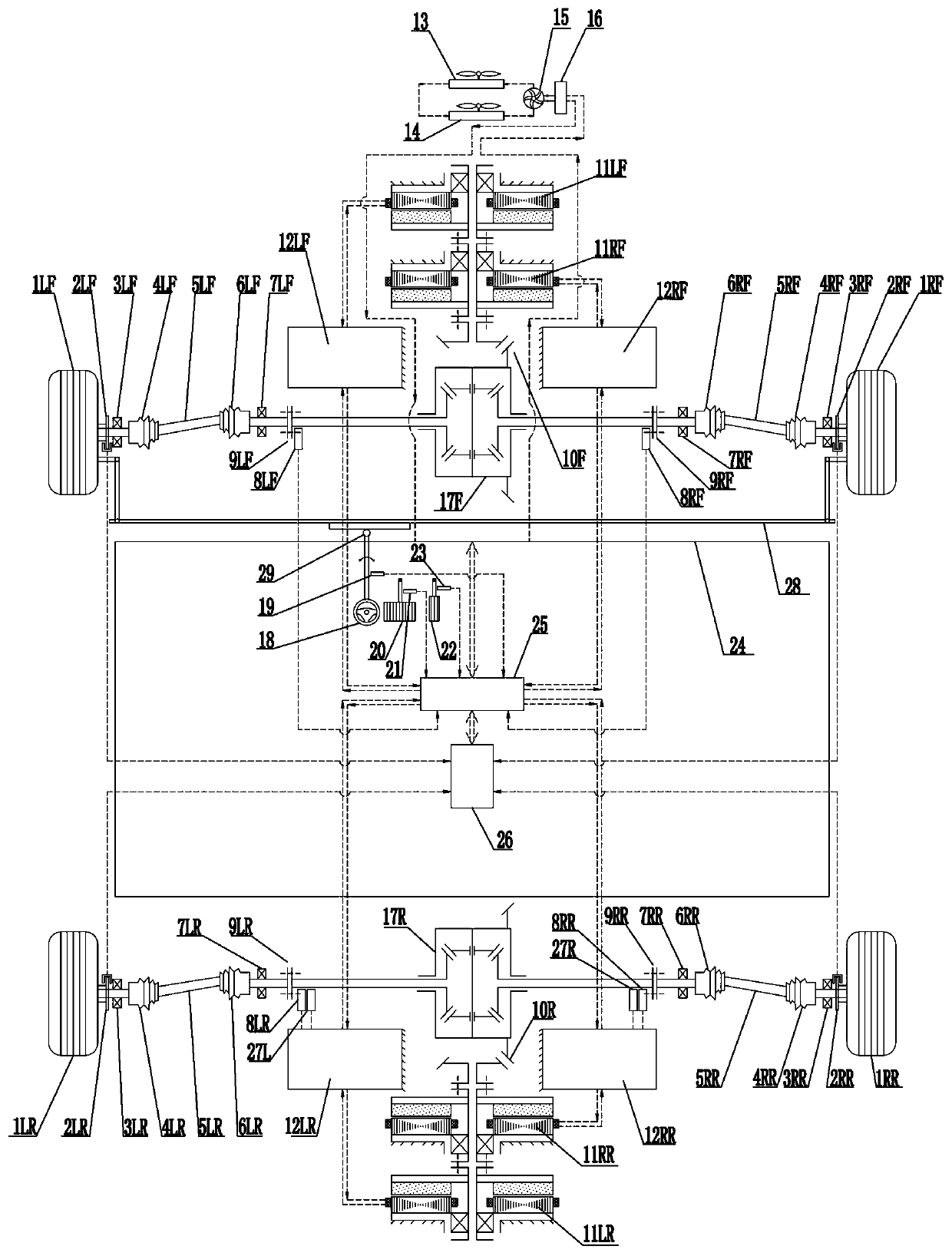

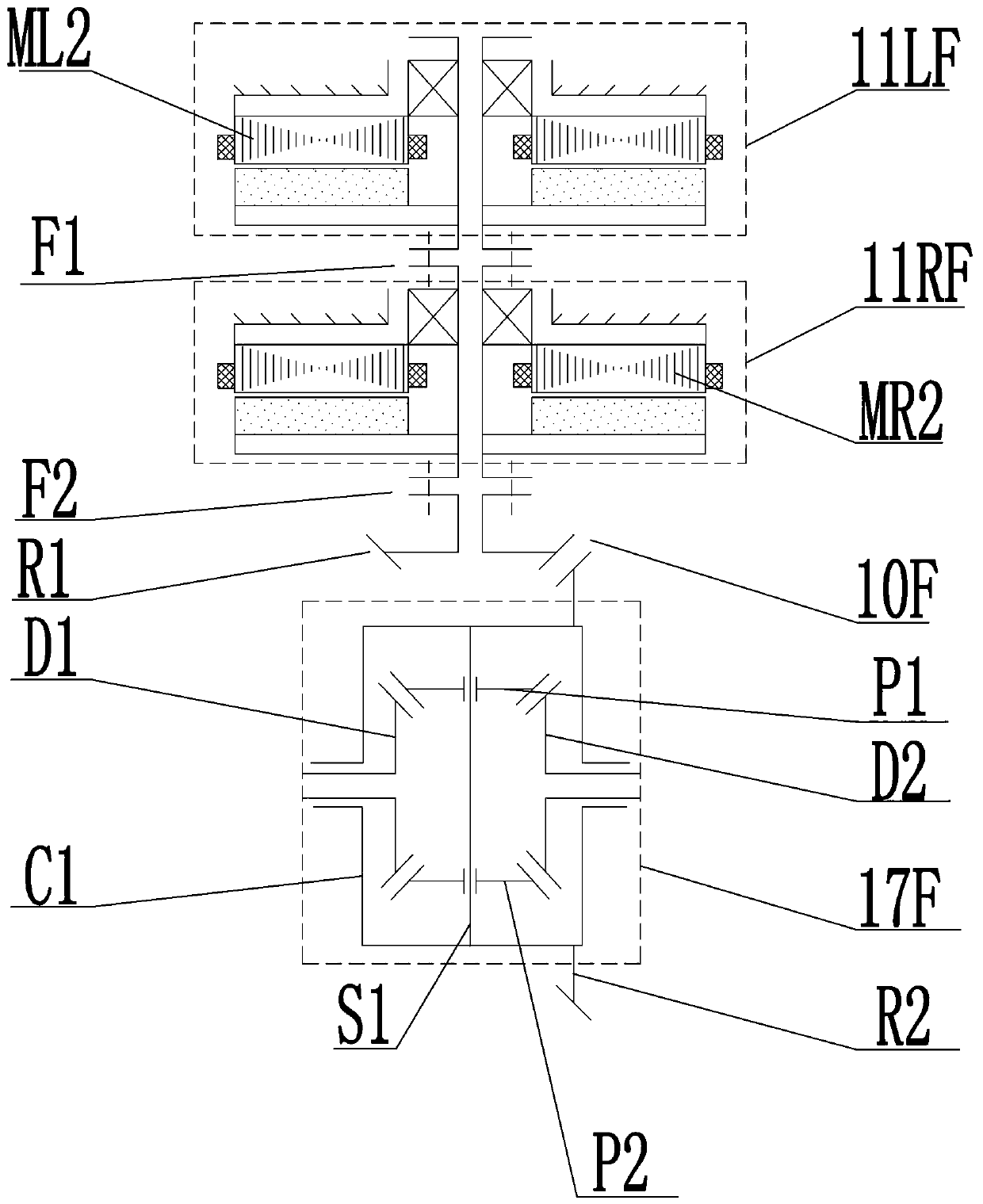

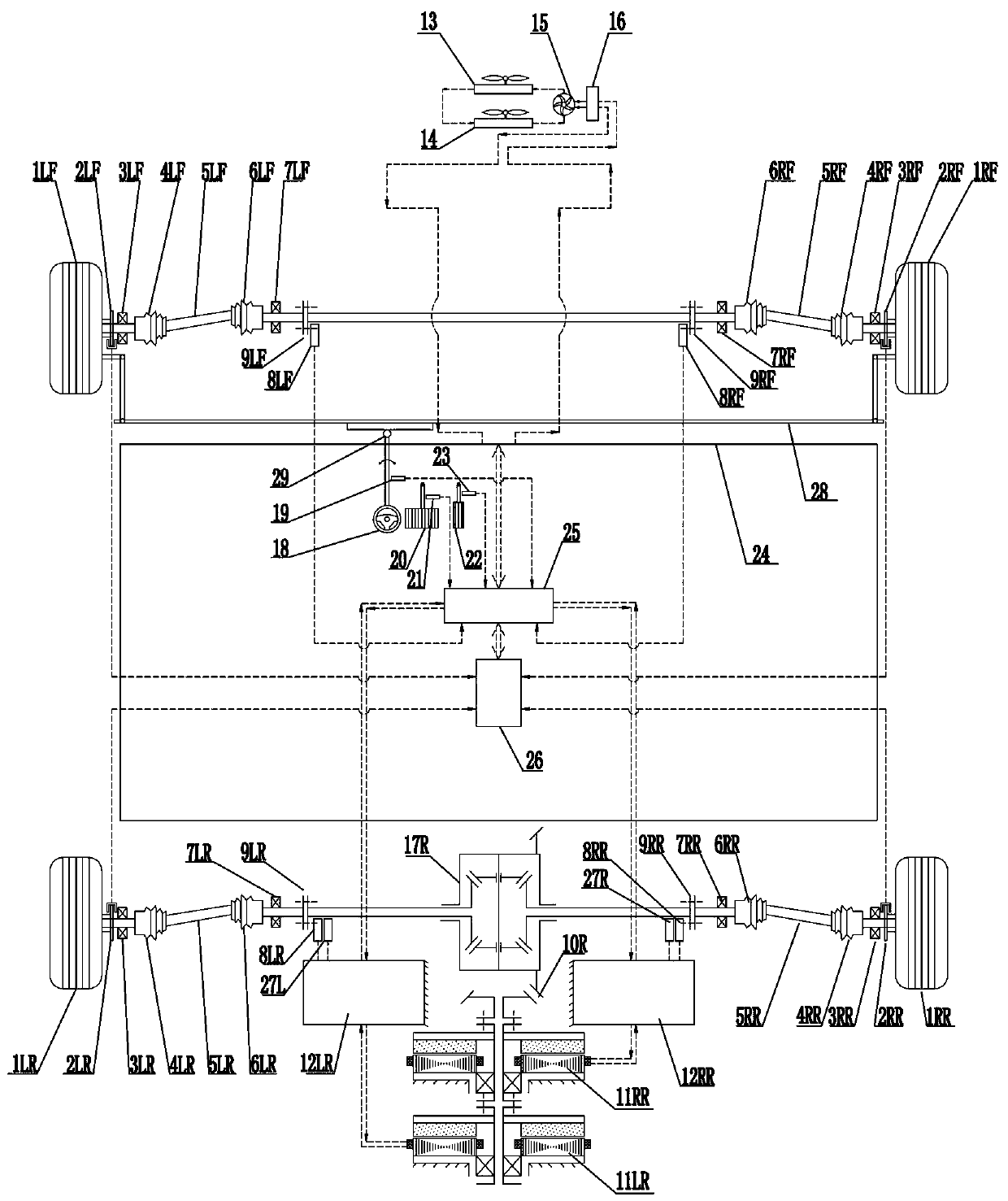

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Such as figure 1 with figure 2 As shown, the present invention is a four-wheel pure electric drive electric vehicle comprising a final drive and a differential. The vehicle layout structure of the present invention adopts the independent suspension design of the front and rear axles, and divides the front axle and the rear axle into four driving half axles respectively. Taking the front axle as an example, the front axle includes four drive half axles 5LF, P1, 5RF, P2, the drive half shaft P1 to which the left gear of the front differential 17F belongs and the left drive half shaft 5LF near the hub. The flange 9LF is connected; the driving half shaft P2 to which the right gear of the front differential 17F belongs is connected with the right driving half shaft 5RF near the wheel hub through the flange 9RF; the connection form of the rear axle is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com