Control method for hydraulic lifting equipment

A technology of hydraulic lifting and control methods, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of insufficient lifting capacity, limited lifting height and space, poor lifting synchronization, etc., to achieve convenient maintenance and balanced load distribution High performance and high synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

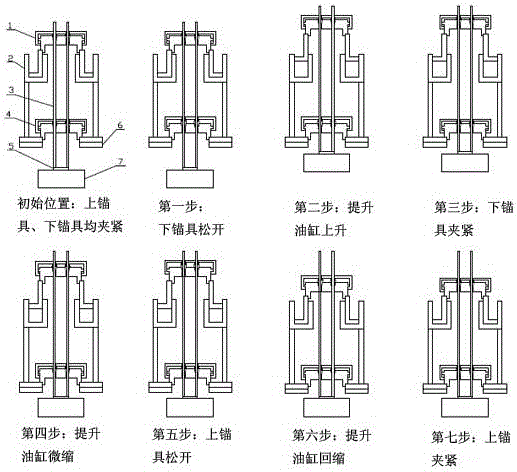

[0013] Next, the preferred embodiments of the present invention will be described in further detail with reference to the accompanying drawings.

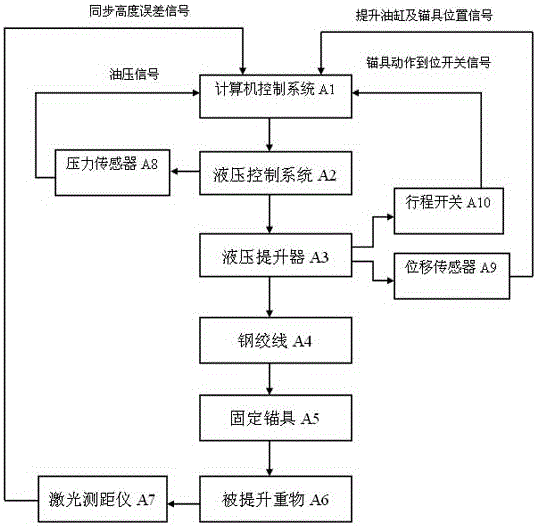

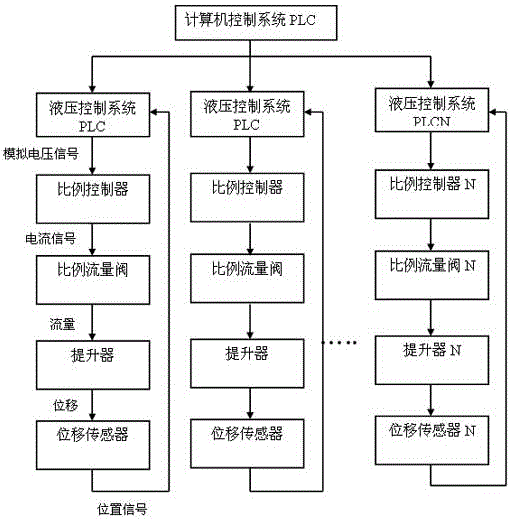

[0014] Such as figure 1 Shown is a schematic diagram of the composition and control relationship of the embodiments of the present invention. The control system includes a computer control system A1, a hydraulic control system A2, and a detection and monitoring system. The detection and monitoring system includes a laser rangefinder A7, a pressure sensor A8, and a displacement sensor. A9, and travel switch A10. The actuator mainly includes hydraulic lifter A3, steel strand A4, and fixed anchor A5. During the lifting construction, the hydraulic lifter A3 is installed on the lifting platform, and the lifting weight A6 is fixed to the steel strand A4 through the fixed anchor A5. When lifting, parameters such as the height of the lifting weight 6, the position signal of the lifting cylinder and the anchor, the pressure of the oil pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com