A method of low-temperature fusion sealing between a device to be packaged and a glass insulating terminal and its application

A technology for encapsulating devices and glass insulation, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low air tightness, low efficiency, and high production costs, and improve the air tightness compliance rate and reliability. performance, reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

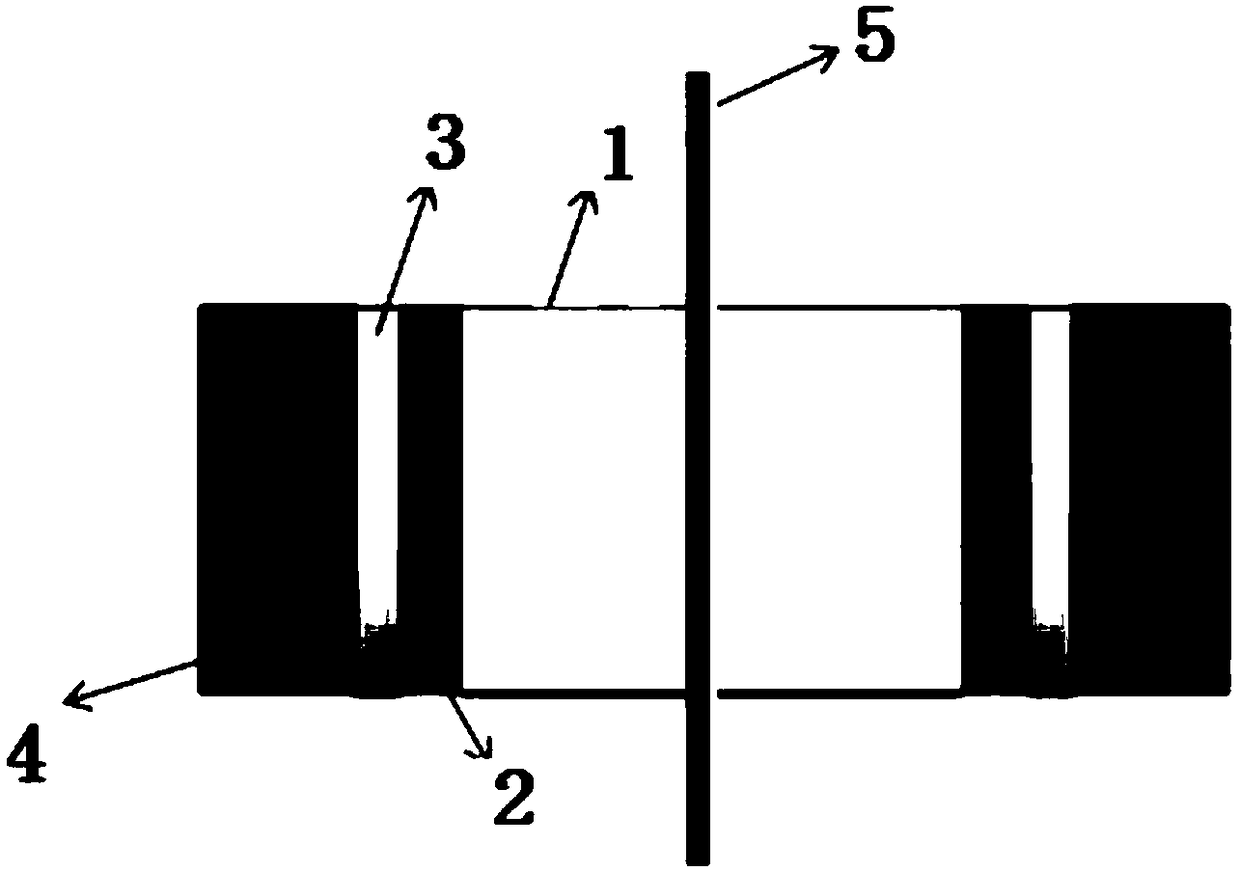

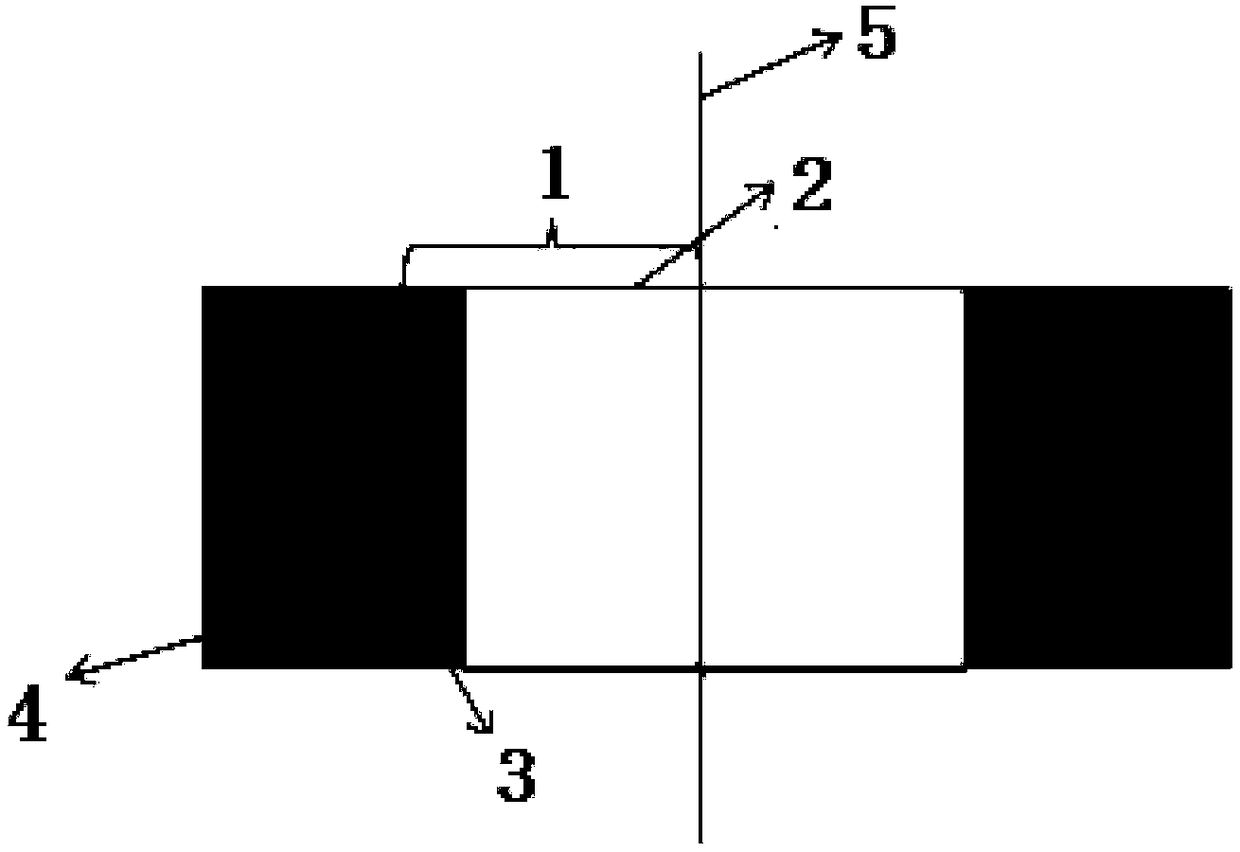

[0014] Specific implementation mode 1: In this implementation mode, a method for low-temperature fusion sealing of a device to be packaged and a glass insulating terminal is specifically carried out according to the following steps:

[0015] A layer of low-melting glass powder is sintered on the outer surface of the high-temperature glass column of the glass insulating terminal to obtain a composite glass column; then the composite glass column is placed in the end hole of the device shell to be packaged, assembled with a jig and directly sintered and packaged, that is Complete the sealing of the device to be packaged and the glass column; the material of the device to be packaged is high-silicon aluminum, aluminum alloy or aluminum-based composite material.

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that: the dielectric constant of the high-temperature glass column of the glass insulating terminal is 4-4.5. Others are the same as the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the melting point of the high-temperature glass column of the glass insulating terminal is 900°C-960°C. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com