Lightweight aggregate concrete small hollow block with a large doping amount of fly ash slag and production method thereof

A technology of lightweight aggregate concrete and hollow blocks, which can be applied to other household appliances, sustainable waste treatment, solid waste management, etc., can solve the problems of high production cost and low feasibility of products, and achieve large waste utilization and earthquake resistance Good effect and large amount of waste slag utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for producing a lightweight aggregate concrete small-sized hollow block, comprising:

[0040] Stir 20 parts of fly ash, 70 parts of furnace bottom slag, and 8 parts of cement with water, vibrate, press, form, and cure to obtain a small hollow block of lightweight aggregate concrete.

Embodiment 2

[0042] A method for producing a lightweight aggregate concrete small-sized hollow block, comprising:

[0043] Mix 50 parts of fly ash, 35 parts of furnace bottom slag, and 15 parts of cement with 7 parts of water, vibrate and press to form, and naturally maintain to obtain a small hollow block of lightweight aggregate concrete.

[0044] During the vibration and pressure molding operation, the power of the molding host is 40kW, the vibration frequency is 100Hz, and the amplitude is 1.2mm.

Embodiment 3

[0046] A method for producing a lightweight aggregate concrete small-sized hollow block, comprising:

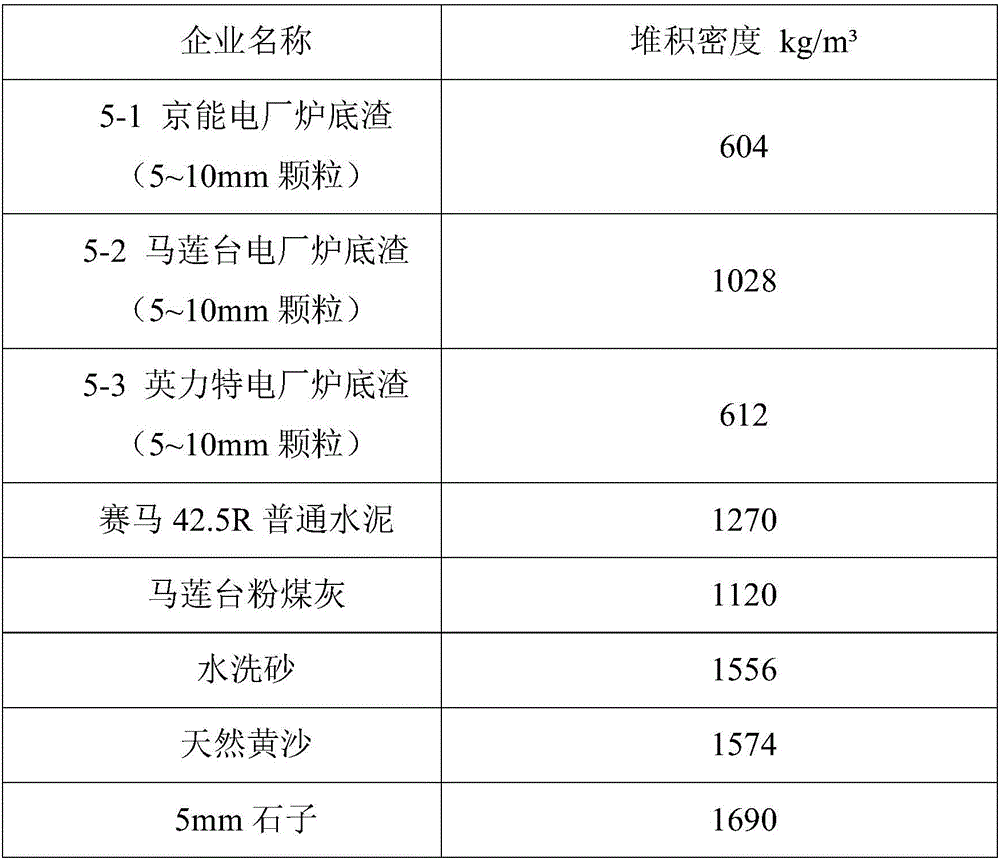

[0047] Stir and mix 30 parts of undisturbed fly ash produced by a thermal power plant, 58 parts of furnace bottom slag with a particle size of 5-10mm, 10 parts of ordinary 42.4R Portland cement and 14 parts of water, vibrate and press to form, and steam curing The light aggregate concrete small hollow block is obtained.

[0048] During the vibration and pressure molding operation, the power of the molding host is 80kW, the vibration frequency is 55Hz, and the amplitude is 1.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com