An integrated reactor for asphalt modification

A technology of asphalt modification and reactor, which is applied in the field of integrated reactors, can solve the problems of reducing heat dissipation area, difficulty in oblique installation, poor heat preservation and energy saving effect, etc., so as to reduce heat dissipation area, improve production efficiency, and install convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

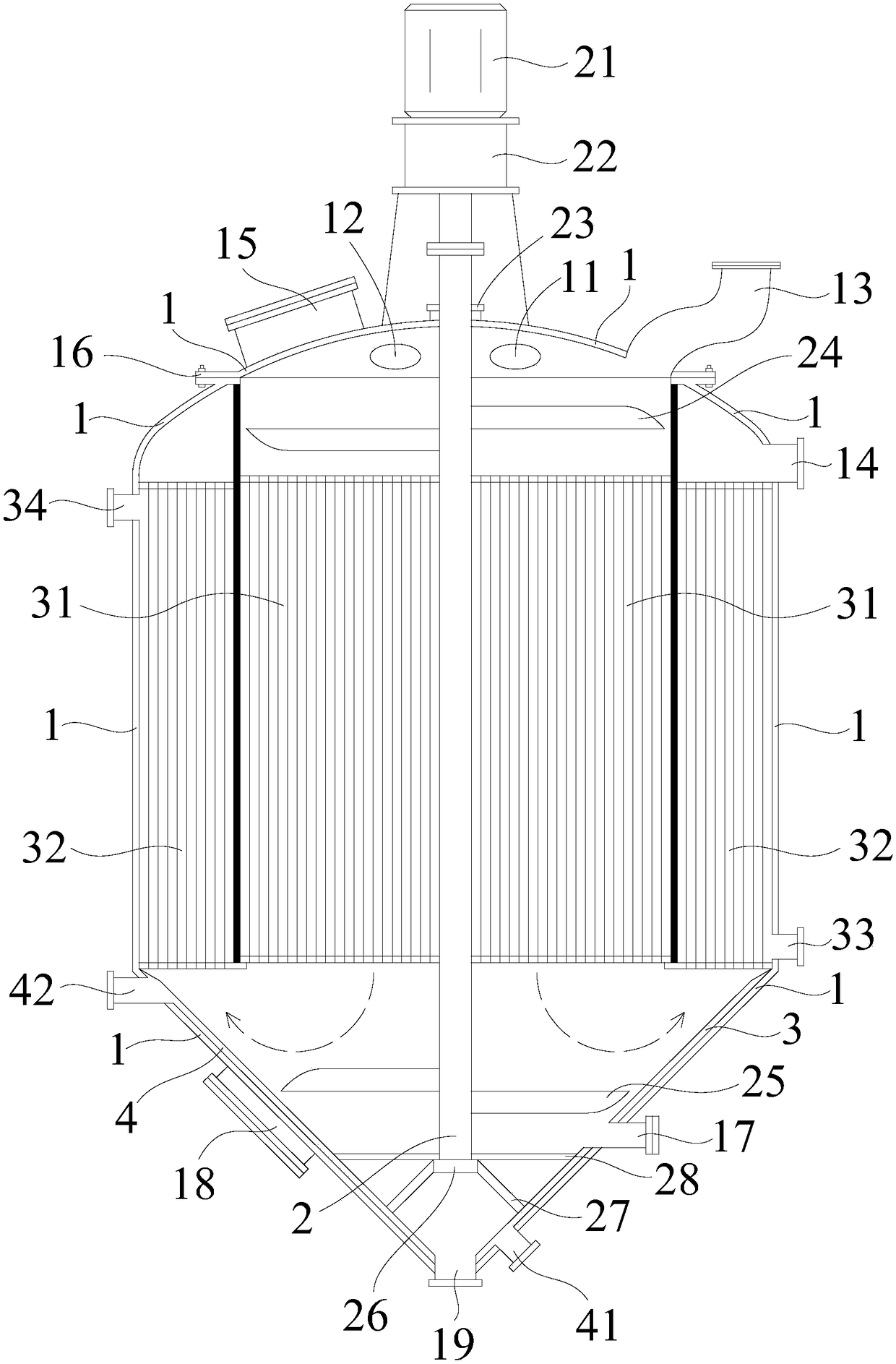

[0033] Such as figure 1 As shown, the structural schematic diagram of an integrated asphalt modification reactor according to the present invention includes:

[0034] The shell 1 is provided with an asphalt inlet 11, a modifier inlet 12, a smoke exhaust port 13, and a finished product outlet 14. The shell 1 is vertically arranged and has a circular cross section;

[0035] A stirring mechanism, which is arranged on the shell 1 and extends into the shell 1, and is used for stirring to mix the asphalt and the modifier;

[0036] The heat exchange reaction mechanism is arranged in the casing 1 and is used for heating the mixed asphalt and modifier to synthesize the reaction, and the stirring mechanism penetrates the heat exchange reaction mechanism;

[0037] The heat preservation mechanism is arranged in the casing 1 and located at the lower part of the heat exchange reaction mechanism, and is used to heat the asphalt and modifier after the synthesis reaction to maintain a viscous state;

...

Embodiment 2

[0046] Such as figure 1 As shown, a schematic structural diagram of an integrated asphalt modification reactor according to the present invention.

[0047] The difference from Example 1 is that in order to solve the problem that the design diameter of the reactor is restricted by the height of transportation (the height of road culverts in China is generally limited to 4.5 meters) and the width, it is also necessary to maximize the height of the reactor within the limited size. For the cross-sectional area of the heat exchange reaction mechanism, the cross section of the shell 1 is square. The tubular heat exchanger with this structure has the problem of uneven swelling and deformation of the shell 1 and can be pulled through Solved by nail-welding the tube heat exchanger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com