A submersible control dam made of basalt fiber composite material

A technology of basalt fiber and composite materials, which is applied in the direction of coastline protection, jetty, pier, etc., can solve the problems of long construction period, high project cost, damage to ecological environment and coastal structure, and achieve strong wind and wave resistance and no secondary pollution , the effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

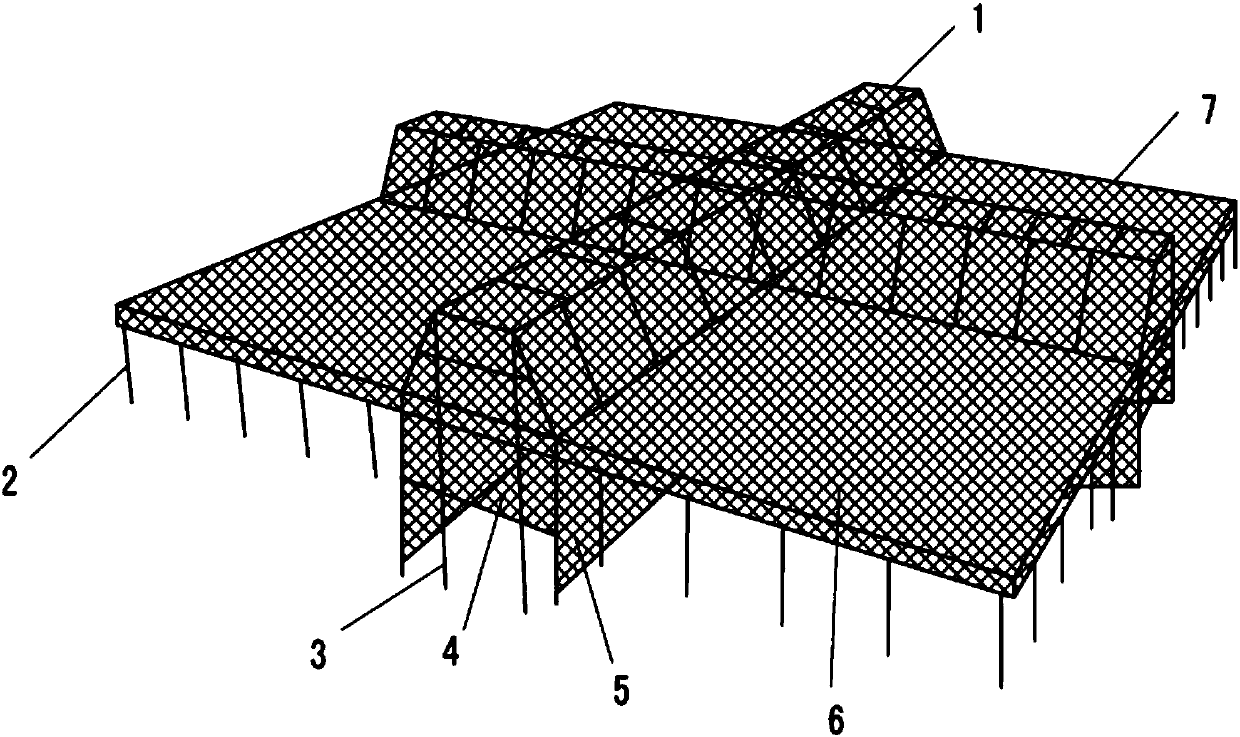

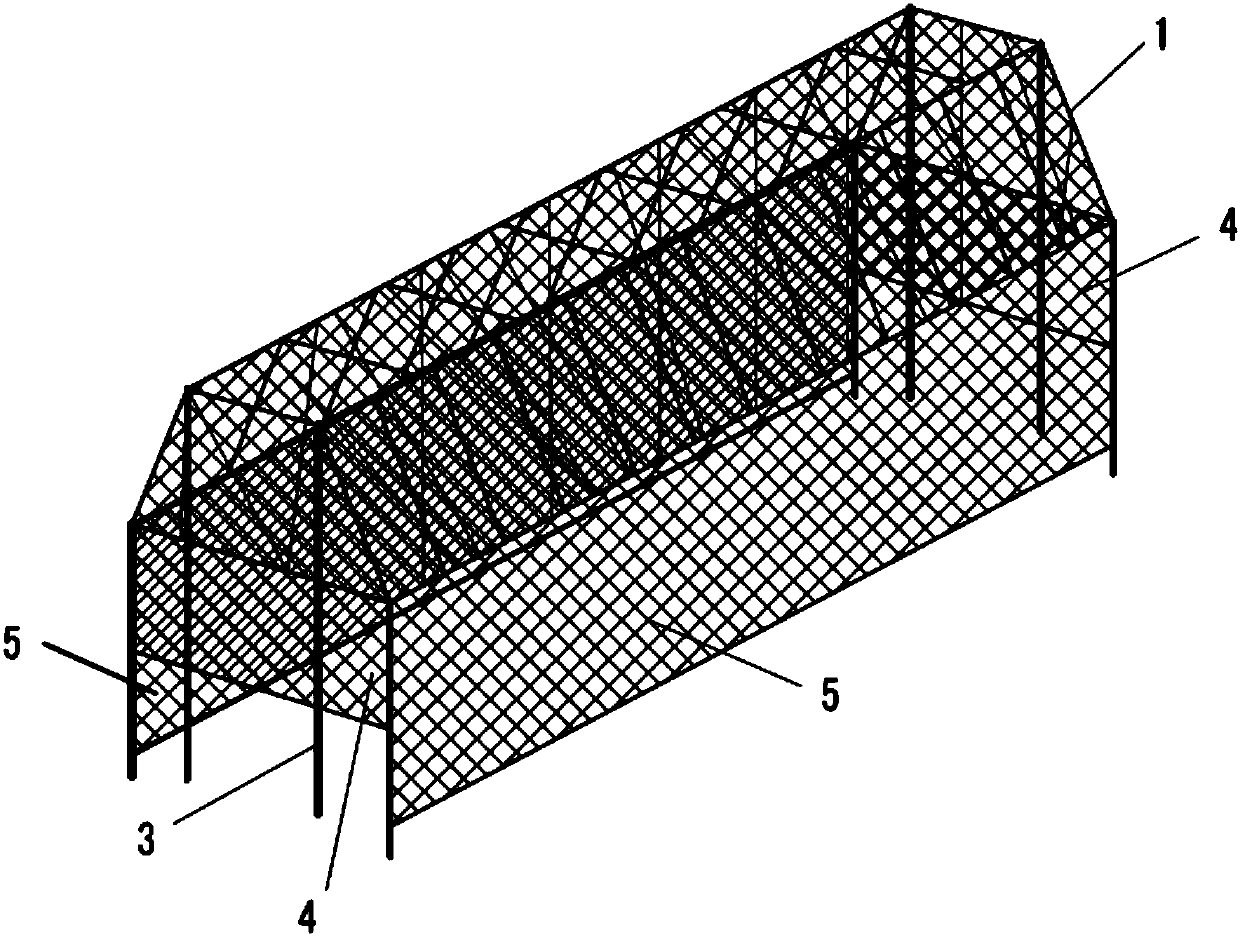

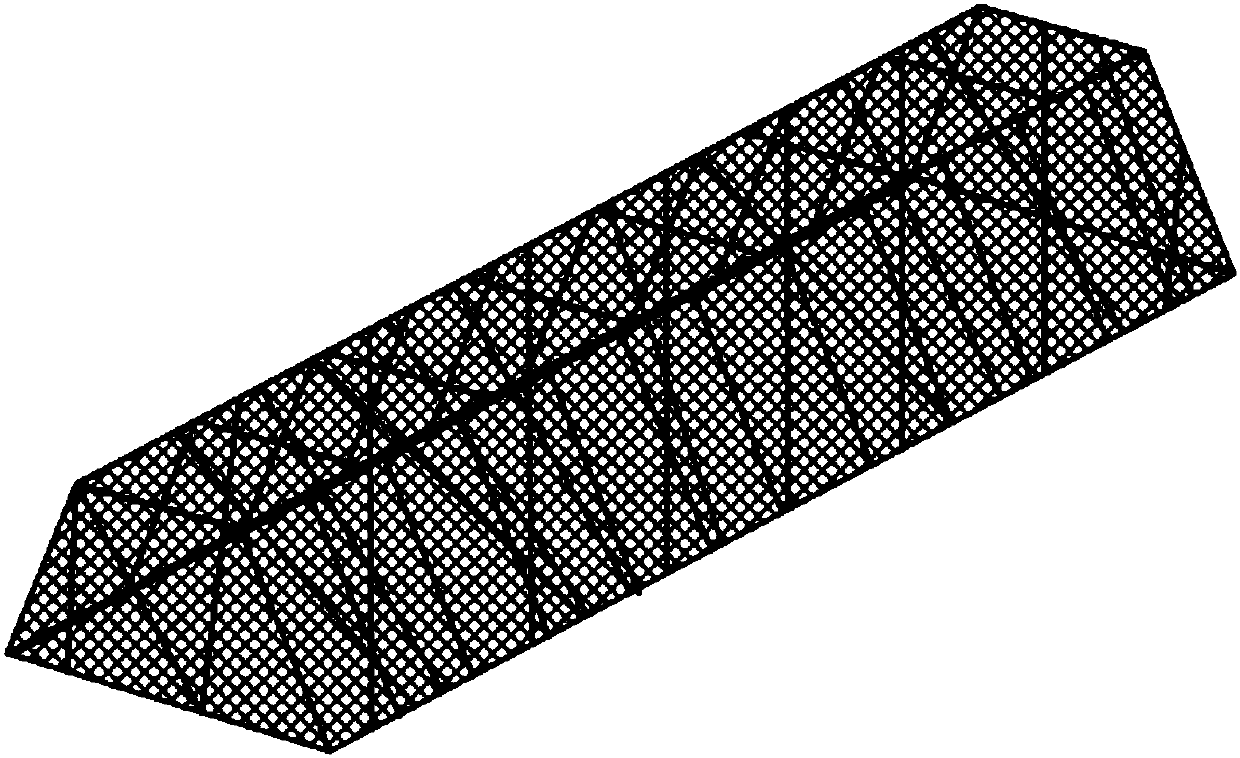

[0020] In order to describe in detail the technical content and structural features of the basalt fiber composite material submersible sand control dam of the present invention, the following will be further described in conjunction with the implementation and accompanying drawings.

[0021] Such as figure 1 , 2 , shown in 3 and 4, the basalt fiber composite material submersible sand-holding dam of the present invention comprises two trapezoidal structure sand-fixing frames 1 of the cross-shaped cross-arranged sand-holding dam, and the sand-fixing wing located at the sand-fixing frame 1 side of the sand-holding dam The net frame 7, the longitudinal sand baffle 5 arranged downwards on the long side of the bottom of the sand fixing frame 1 of the sand dam, and the horizontal sand baffle 4 arranged downward on the short side of the bottom of the sand fixing frame 1 of the sand dam; The bottom of 1 is evenly provided with the fixed column 3 of the sand-stopping dam, and the botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com