Assembly type concrete column partially and externally wrapped by H-shaped steel and energy dissipation steel plate shear wall structure

A technology of outsourcing concrete and steel plate shear walls, applied in the direction of walls, building components, building types, etc., can solve the problems of insufficient ductility and energy dissipation capacity, decreased bearing capacity, buckling instability of steel plates, etc., to improve the seismic performance and deformation. capacity, compressing the base cost, and reducing the effect of the structure's own weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

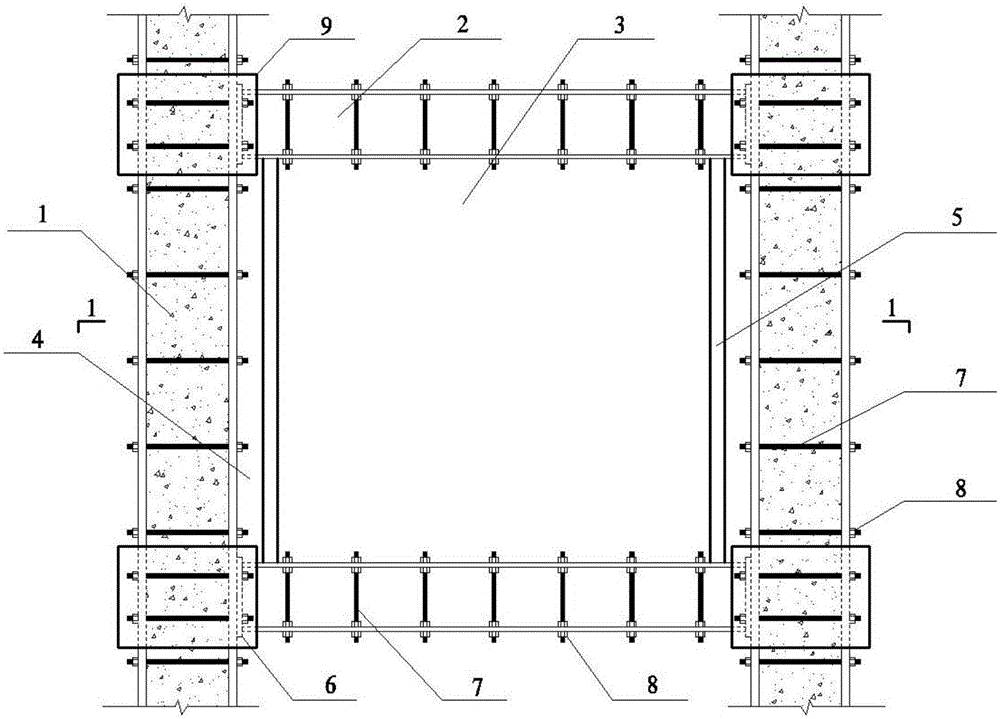

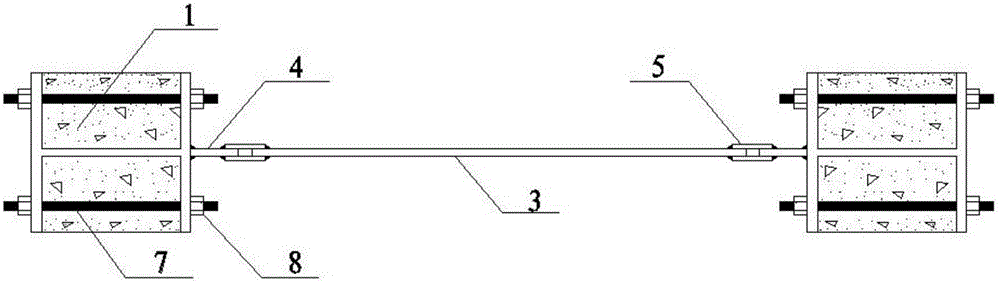

[0017] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides a kind of fabricated H-shaped steel partially outsourcing concrete column-energy-dissipating steel plate shear wall structure including vertical frame column 1, horizontal frame beam (transverse beam) 2 and the frame beam and frame column Steel plate shear walls between 3.

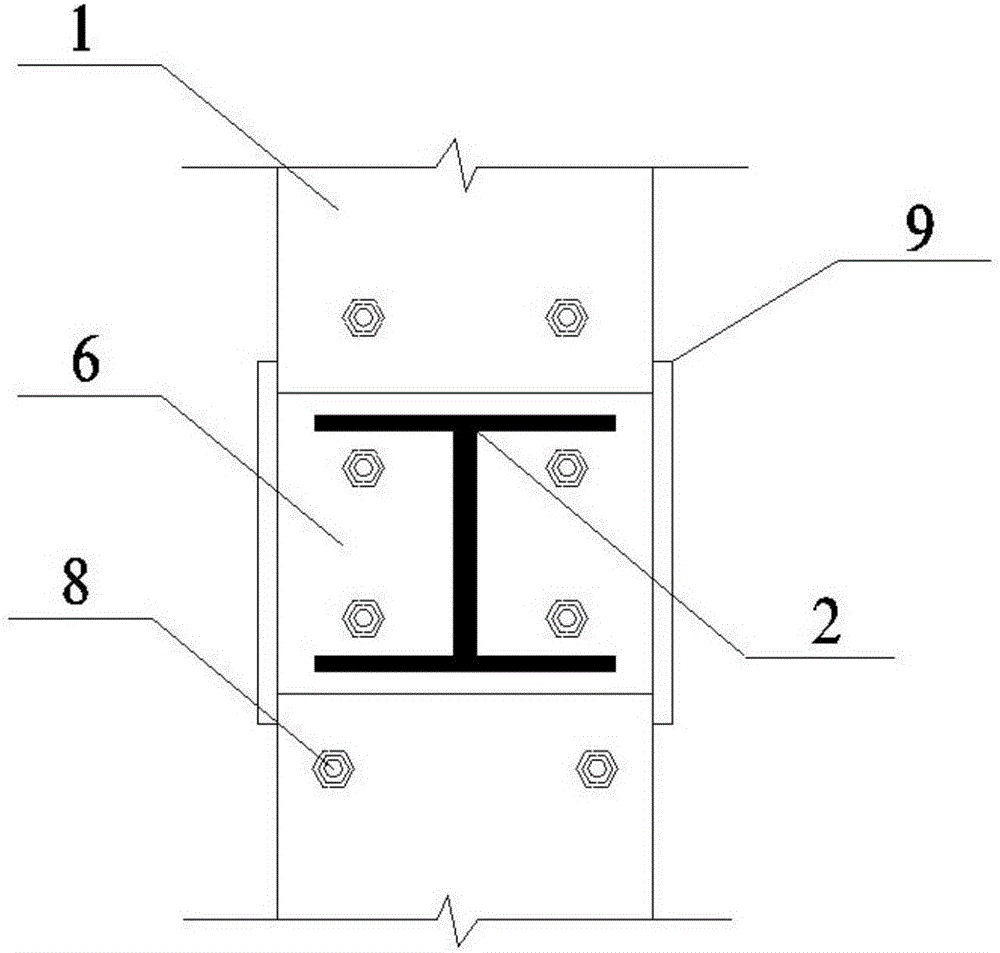

[0018] Among them, the steel plate shear wall adopts steel with low yield strength and high ductility, and the frame column adopts H-shaped steel concrete column with double-sided flange and tie rod 7. The horizontal beam adopts H-shaped steel beams with upper and lower flange plates and restraint rods. The restraint rods on the H-shaped steel flange plates of the beams and columns are drilled on the flange plates and penetrated by full-thread screws and connected with high-strength friction bolts 8 . The end of the H-shaped steel beam is provided with an end plate 6, and the end plate is welded to the H-shaped st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com