Radiation curable coating decorative board

A radiation-cured and decorative board technology, applied in the field of building decoration materials, can solve the problems of narrow application, weak decoration, and low cost, and achieve the effects of low cost, rich color patterns, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

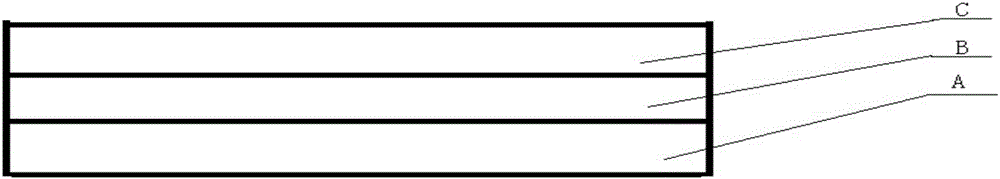

[0028] A radiation-cured paint decorative board is produced according to the following steps: (1) the oriented strand substrate A is subjected to thickness-setting treatment and surface treatment through a thickness-calibrating sander; (2) a colored primer layer B is coated on the substrate A (3) radiation curing; (4) surface sanding and dust removal on the basis of step (3); (5) coating color coating or ink layer C on the basis of step (4); (6) radiation curing ; (7) inspection; (8) paste protective film; (9) packaging.

Embodiment 2

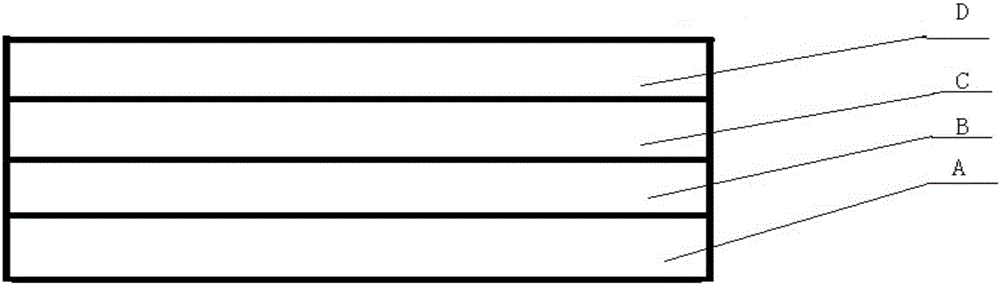

[0030] A radiation-cured paint decorative board is produced according to the following steps: (1) a wood wool substrate A is subjected to thickness-setting treatment and surface treatment through a thickness-calibrating sander; (2) a color primer layer B is coated on the surface of the substrate A; (3) radiation curing; (4) surface sanding and dust removal on the basis of step (3); (5) coating color coating or ink layer C on the basis of step (4); (6) radiation curing; (7) coating the transparent varnish layer D on the basis of step (6); (8) radiation curing; (9) inspection; (10) sticking a protective film; (11) packing.

Embodiment 3

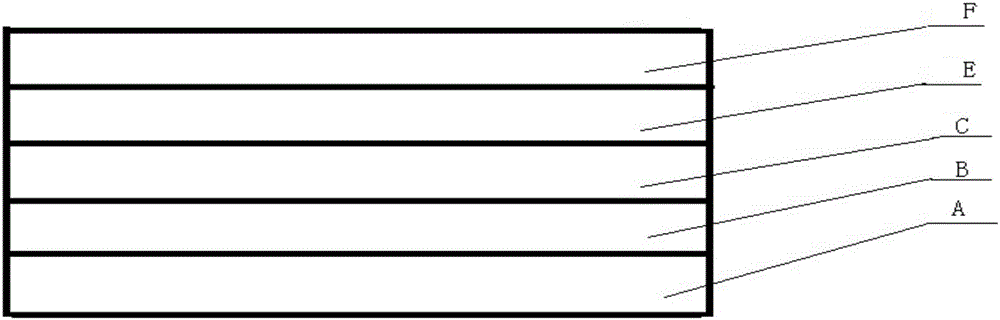

[0032] A radiation-cured paint decorative board is produced according to the following steps: (1) the straw substrate A is subjected to thickness-setting treatment and surface treatment through a thickness-calibrating sander; (2) a color primer layer B is coated on the surface of the substrate A; ( 3) radiation curing; (4) surface sanding and dust removal on the basis of step (3); (5) coating color coating or ink layer C on the basis of step (4); (6) radiation curing; ( 7) coating water-based inorganic gel layer E on the basis of (6); (8) coating water-based photocatalyst sterilization, sterilization, antifouling layer F on the basis of (7); (9) inspection; (10) Paste protective film; (11) packing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com