Hydraulic climbing type elevator shaft finalization operation platform and construction method

An operating platform and elevator shaft technology, which is applied in the construction field of hydraulic self-climbing elevator shaft stereotyped operating platform, can solve the problems of inconvenient construction waste cleaning, difficult formwork support, troublesome dismantling, etc., so as to reduce labor costs and time costs. , The effect of simplifying the construction process and improving the construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

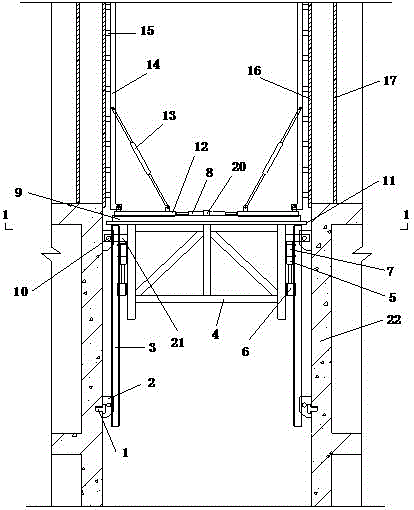

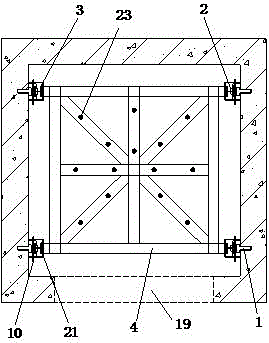

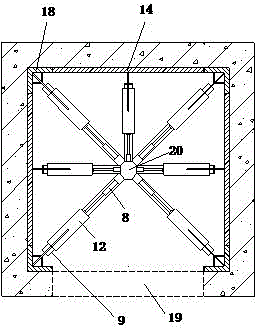

[0035] Such as figure 1 As shown, according to the design requirements, I-shaped steel or steel pipes are used to weld a double-layer truss structure operation platform 4, two connectors 21 are welded on both sides of the upper I-shaped steel beam of the operation platform 4, and two connectors 21 are welded on both sides of the upper I-shaped beam of the operation platform 4. Evenly weld the positioning bolts 23 for the installation of the ejection track 9 on the profiled steel beam; make the platform plate 11 according to the size of the operating platform, and the platform plate 11 can be selected from 5mm steel plate or 20mm wood plywood, and the prepared platform plate 4 is laid on the operating platform. On the platform 4; the ejection track 9 is fixed on the operating platform 4 by positioning bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com