Intelligent three-dimensional garage control system based on CAN bus and control method

A CAN bus, three-dimensional garage technology, applied in general control systems, control/regulation systems, program control in sequence/logic controllers, etc., can solve problems such as poor display and word processing capabilities, insufficient testing, and too many wiring harnesses , to achieve high-speed and reliable data transmission, reduce the amount of electrical construction, and simplify the system wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

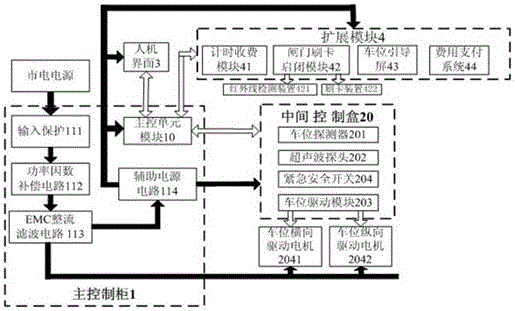

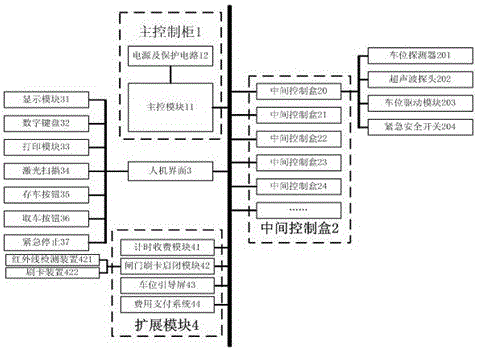

[0031] like figure 1 As shown, according to an embodiment of the present invention, this embodiment discloses a CAN bus-based intelligent three-dimensional garage control system, including a main control cabinet 1 for controlling the entire garage electrical system, and the main control cabinet 1 includes a power supply A protection circuit 11 and a main control module 10, the power protection circuit 11 includes an input protection circuit 111, a power factor compensation circuit 112, an EMC rectification filter circuit 113 and an auxiliary power supply circuit 114, wherein one end of the input protection circuit 111 is connected to the commercial power supply Connected, the other end is connected with the power factor compensation circuit 112, one end of the EMC rectification filter circuit 113 is connected with the power factor compensatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com