Blast hole defender and manufacturing method and application method thereof

A manufacturing method and a technology of a hole protector, which are applied to drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve problems affecting the porosity rate, collapse, and large water volume, and achieve simple processing and manufacturing processes and reduce The effect of rinsing and soaking, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The production method of the blast hole protector unit:

[0035] 1) cutting, take an iron plate with a thickness of 4-6mm, and cut the iron plate into a rectangular iron plate with a width of 1.1-1.3m by water welding;

[0036] 2) Bending, bending the iron plate into a cylindrical structure with a plate rolling machine, the inner diameter of the cylindrical structure is 337-340mm, and the outer diameter is 347-350mm;

[0037] 3) Welding, the seams are welded by electric welding to make a hole protector unit.

[0038] Preferably, the manufactured hole protector unit has a height of 1.2m, a thickness of 5mm, an inner diameter of 338mm, and an outer diameter of 348mm. Design parameters determined according to drilling rig equipment

[0039] The diameter of the prepared hole protector unit is larger than the diameter of the blasthole and smaller than the broken diameter of the blasthole. The so-called broken diameter of the blasthole is the diameter of the smallest circl...

Embodiment 2

[0041] Application of Blast Hole Protector

[0042] The blast hole protector is welded up and down by two hole protector units, and the method for applying the blast hole protector in the blast hole includes the following steps:

[0043] a) Drill holes to a depth of 2m with drilling equipment;

[0044] b) Place one hole protector unit vertically at the blasthole opening so that the center of the cross-section of the hole protector unit coincides with the center of the blasthole cross-section;

[0045] c) On the upper end cover iron plate of the hole protector unit, use the drill bit of the drilling equipment to press down the hole protector unit until the upper end of the hole protector unit is at a height of 0.2-0.4m from the ground;

[0046] d) Continue drilling to 4m with drilling equipment;

[0047] e) Weld the second hole protector unit on the upper end of the first hole protector unit, cover the upper end of the second hole protector unit with an iron plate, and press ...

Embodiment 3

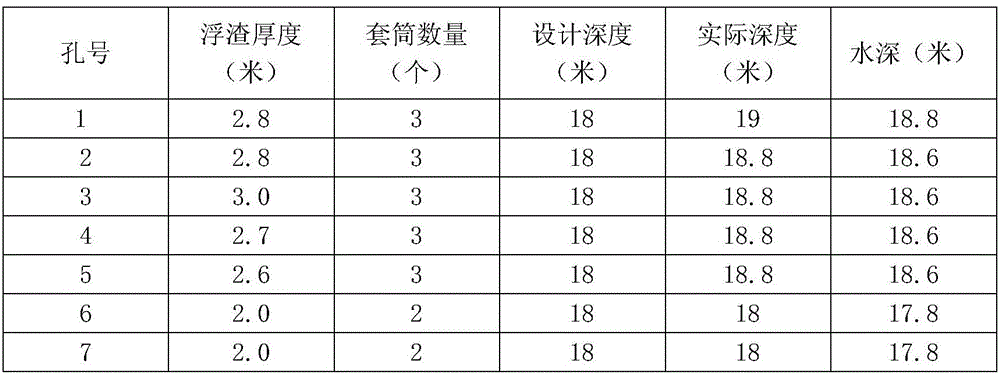

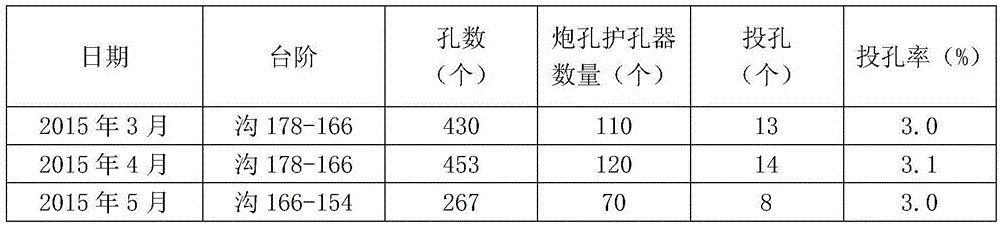

[0051] On-site test of blast hole protector

[0052] Test 7 groups of blast hole protectors in the horizontal tooth 10 penetration area of ditch 178-166, and measure the holes on site after blasting (see the table below).

[0053]

[0054] It can be seen from the above table that although the efficiency of the roller cone drilling machine is reduced by about 85% when using the technology of the blast hole protector, the hole formation rate of the piercing area (referring to the blast hole drilled by the roller cone, one drilling can reach The percentage of blastholes required by the design to the total blastholes in the piercing area) is 3-5 times that of the original, and the blasting quality has been greatly improved in the trench digging and other key blasting areas with thick scum and a lot of water, which is a good example for subsequent blasting. Both shoveling and production advancement have played a positive role.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com