Dynamic sealing and pressure compensation structure for shear valve slurry pulser

A technology of pressure compensation and mud pulse, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of short working time of pressure compensation mechanism, complicated pressure compensation structure, inconvenient maintenance, etc., and achieve simple operation and maintenance , Reliable mechanical connection and effective sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present application will be described in detail below with reference to the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

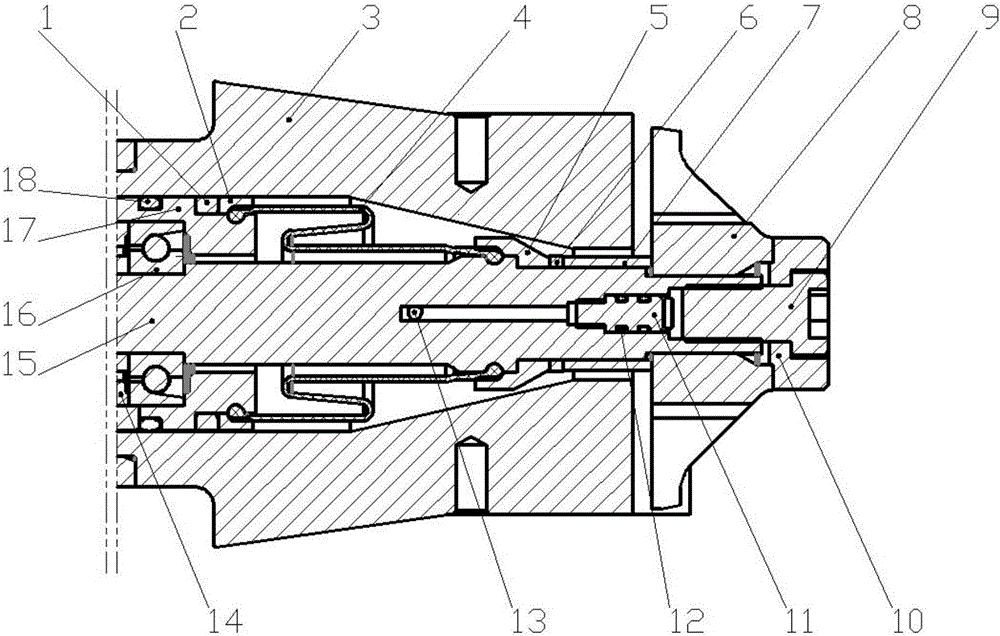

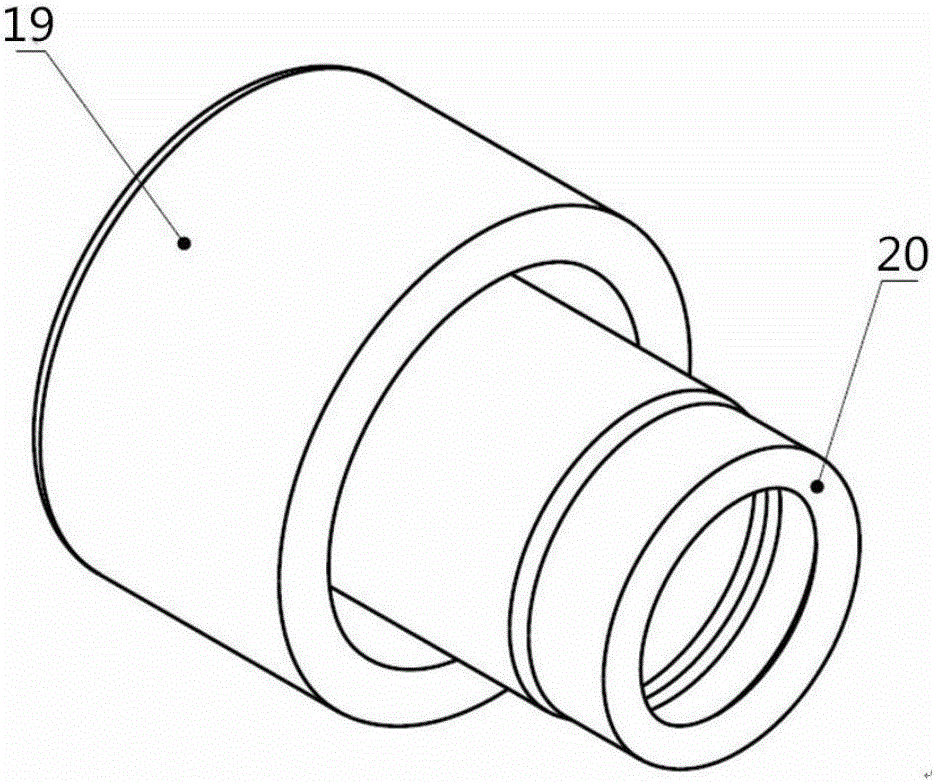

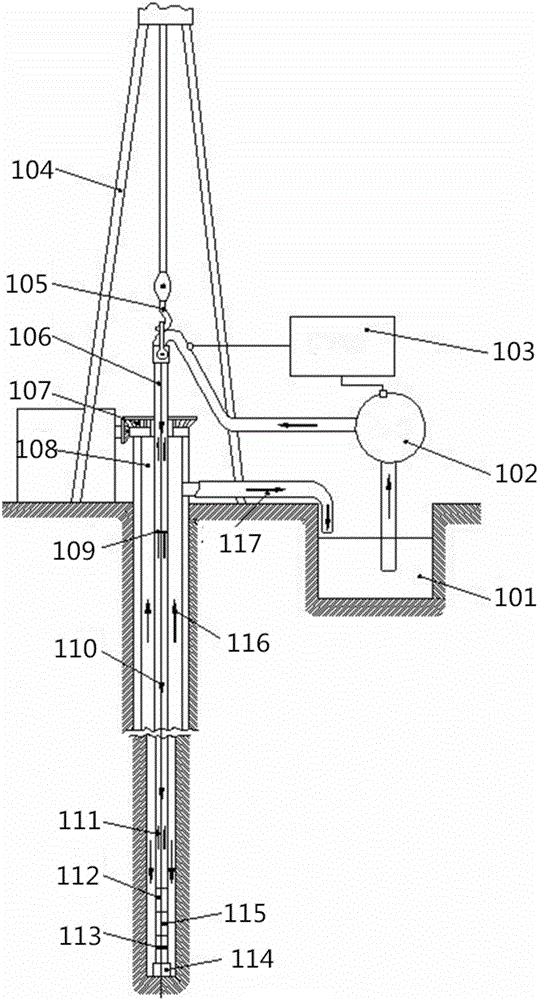

[0043] The present invention proposes the technical scheme by comprehensively considering dynamic sealing, pressure compensation, motor oil immersion, motor internal flow channel, rubber cartridge structure protection, etc.; among them, dynamic sealing, the rotor (valve plate) of the shear valve pulser When working, it swings back and forth. In the transmission system from the output shaft of the power end to the rotor, the rotor directly contacts the mud, and the output shaft of the motor must have a reliable seal. Structurally, a dynamic seal should be used. Pressure compensation, the shear valve pulser needs to bear the influence of the static pressure of the mud column, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com