Integrated displacement amplifying mechanism and moving method thereof

A displacement amplification mechanism and integrated technology, which is applied in the direction of machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve the problems that the displacement is difficult to meet the requirements, the natural cooling speed is slow, and the response time of the mechanism is slow. High weight ratio, faster action speed, and simple appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

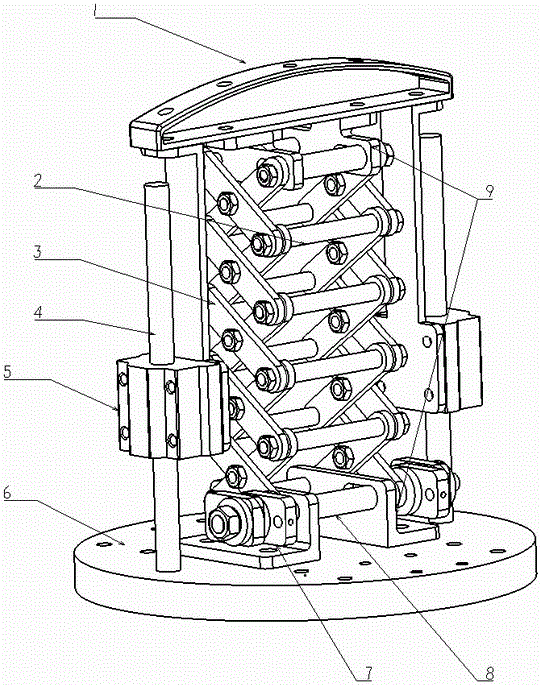

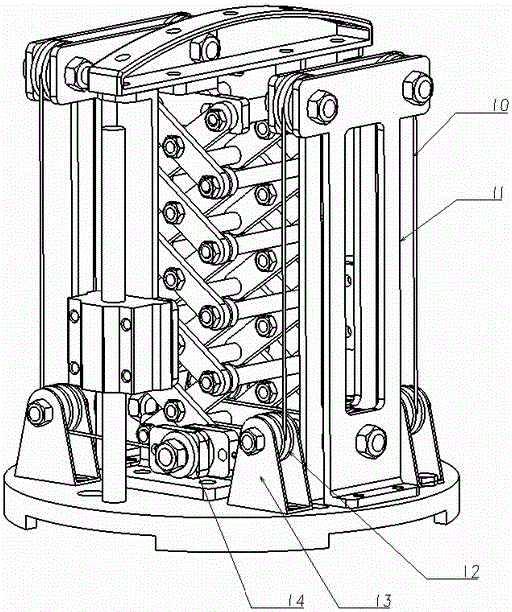

[0039] The integrated displacement amplification mechanism driven by shape memory alloy provided by the present invention includes the base 6, the top seat 1 and the displacement system between the base 6 and top seat 1, and the displacement system includes a mechanical motion system and a shape memory alloy wire drive system;

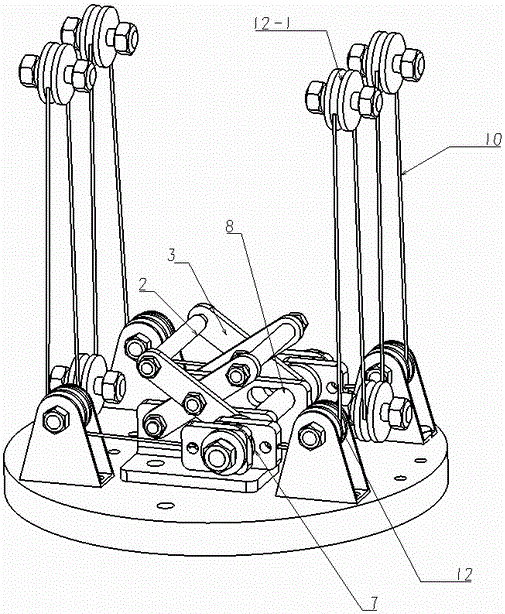

[0040]The mechanical motion system is fixedly connected between the base and the top seat, adopts a scissor-type lifting displacement structure, and is provided with a displacement input end, which is connected to the shape memory alloy wire drive system; the mechanical motion system includes a bottom chute support Seat, top chute support, transverse shaft 2, scissor arm 3, horizontal movement shaft 8 and terminal 7 bottom chute supports are fixed on the base in pairs, and the bottom chute supports are connected with horizontal movement shafts 8. The top chute support and the bottom chute support are correspondingly arranged and fixed on the top seat 1,...

Embodiment 2

[0045] As a preferred embodiment of the present invention, a sleeve is set on the outside of the integrated displacement amplifying mechanism. The sleeve includes a sleeve box body and a baffle 17. The mechanical movement system and the shape memory are connected by the baffle 17 inside the sleeve. The alloy wire driving system is separated; on the top surface of the sleeve, the middle part is open, and end caps are arranged on both sides. The end caps are divided into two layers. The cover plate of the trachea 15; several base ventilation holes 16 are distributed on the base.

[0046] Figure 4 and Figure 5 The overall mechanism is installed and inserted into the sleeve, and a groove is opened in the middle of the sleeve to facilitate the operation of the amplification mechanism. Secondly, two U-shaped grooves are opened on the side of the baffle plate 17 to separate the mechanical motion system from the drive system by passing the SMA wire, and to close the drive system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com