Three-level-roots-water ring intelligent frequency converting control vacuum system and control method thereof

A frequency conversion control and vacuum system technology, applied in pump control, non-variable pumps, liquid fuel engines, etc., can solve the problems of large backflow, low operating efficiency, high energy consumption, etc., and achieve obvious energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

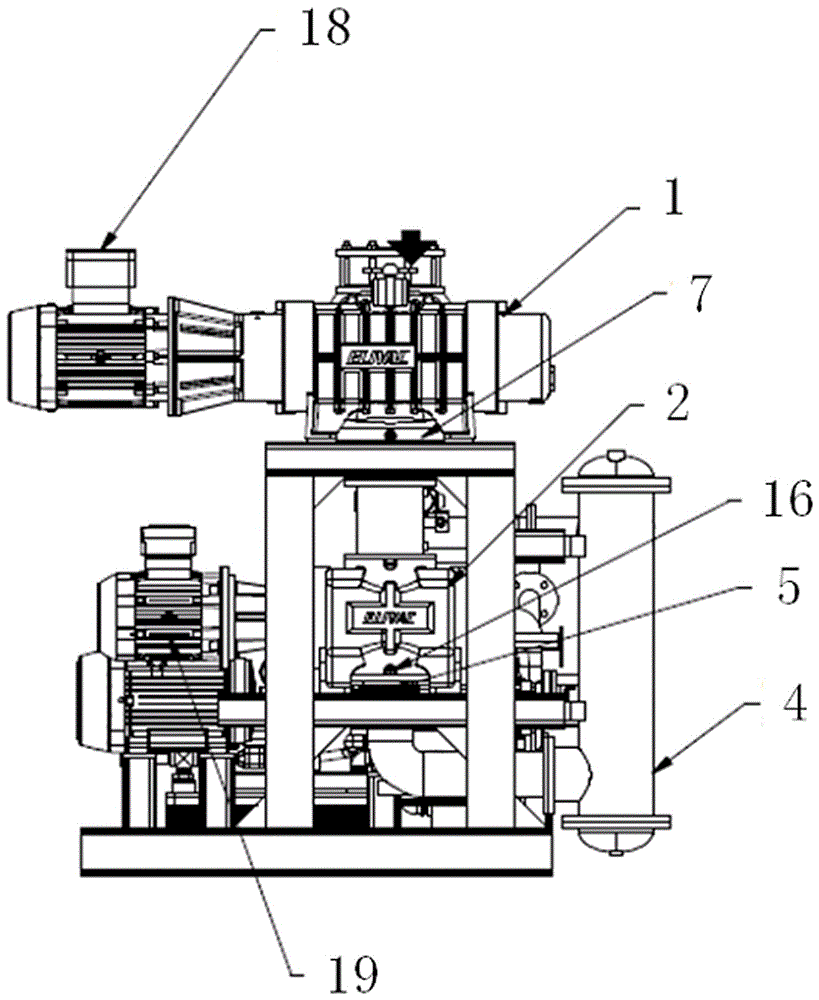

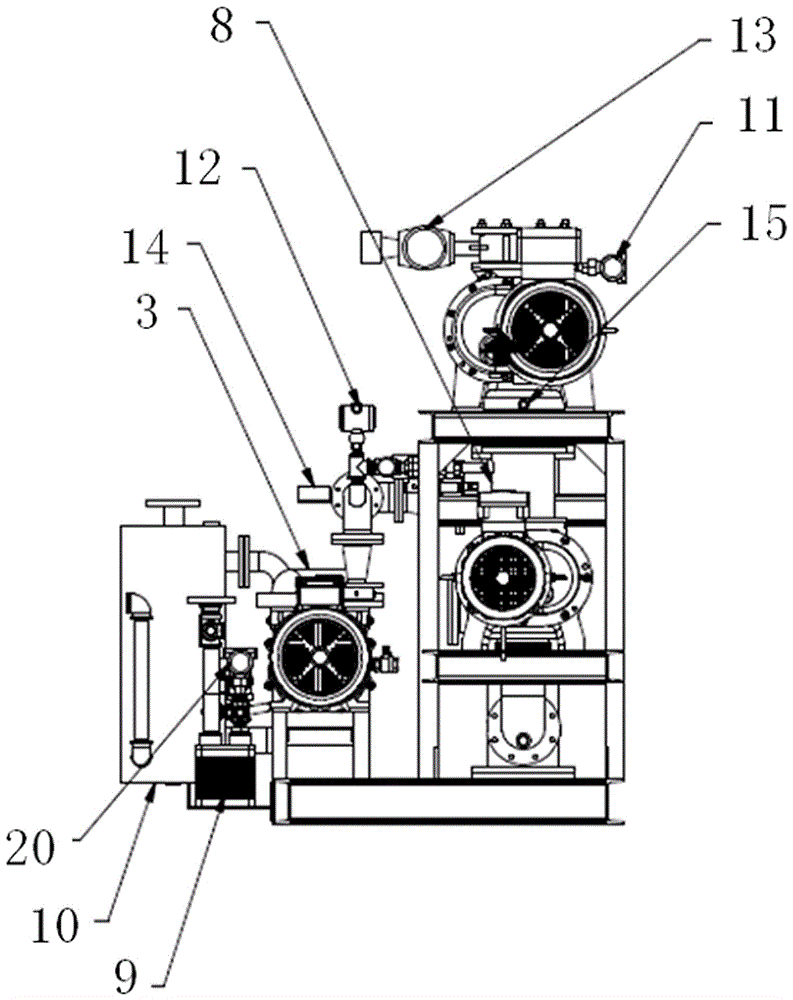

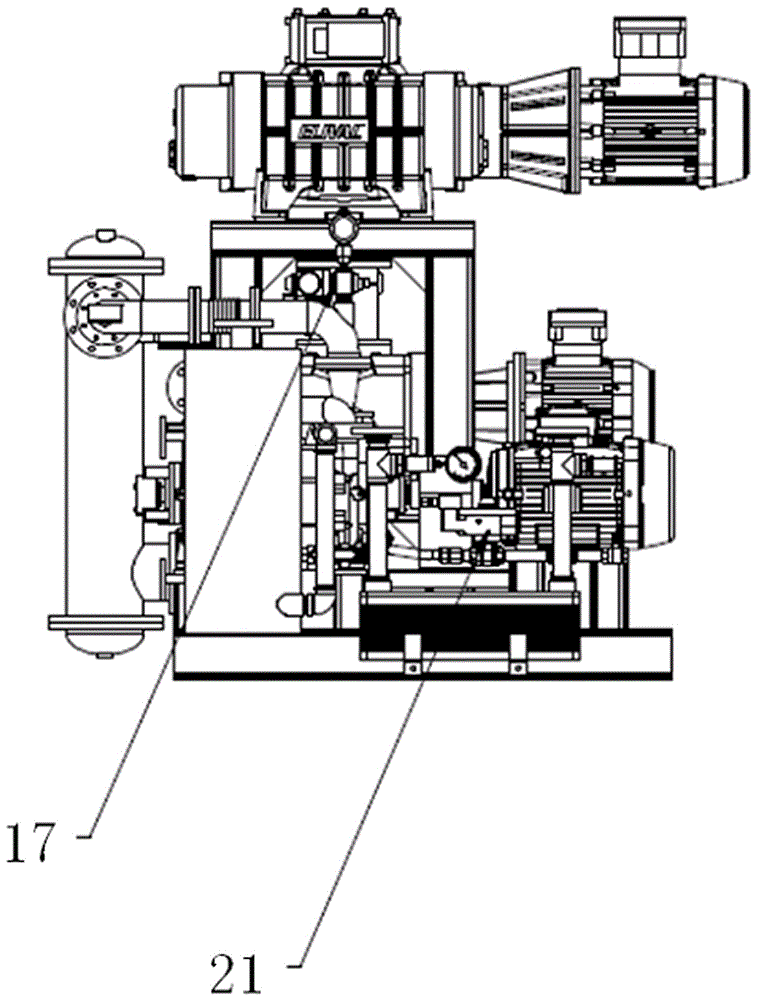

[0026] The figure includes the first-stage Roots mechanical vacuum pump 1, the second-stage Roots mechanical vacuum pump 2, the front-stage traction pump double-stage liquid ring pump 3, the second-stage Roots mechanical vacuum pump exhaust outlet cooler 4, the first-stage Roots mechanical vacuum pump Built-in spiral coil cooler 7 of the mechanical vacuum pump, exhaust cooler of the first-stage Roots mechanical vacuum pump 8, circulating fluid heat exchanger 9, gas-water separator 10, vacuum pressure transmitter at the inlet of the first-stage Roots mechanical vacuum pump 11. 2-stage Roots mechanical vacuum pump outlet pressure transmitter 12, vacuum inlet pneumatic shut-off valve 13, liquid ring pump suction inlet temperature transmitter 14, 1-stage Roots mechanical vacuum pump exhaust cavity temperature transmitter 15, 2 Stage 1 Roots Mechanical Vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com