Efficient steam and hot water boiler

A hot water boiler and steam technology, applied in the field of hot water boiler and high-efficiency steam, can solve the problems of small furnace, low thermal efficiency, insufficient heat supply, etc., achieve faster manufacturing speed, increase heat exchange area, and clean up ash convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

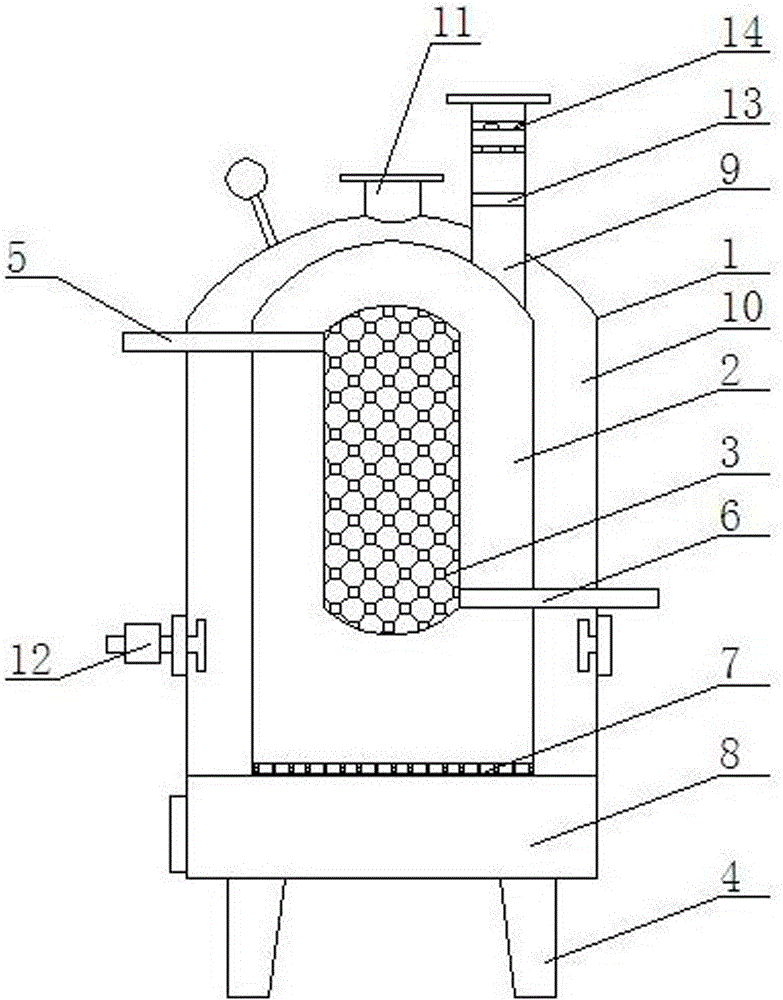

[0014] As shown in the figure, a high-efficiency steam and hot water boiler includes a furnace body 1, a combustion chamber 2, a heating water tank 3, and support feet 4. The bottom end of the furnace body 1 is supported by a plurality of support feet 4, and the furnace body 1 internal device combustion chamber 2, the internal device of the combustion chamber 2 is the heating water tank 3, the cold water inlet pipe 5 passing through the furnace body 1 is installed on the left upper end of the heating water tank 3, and the hot water outlet pipe 6 passing through the furnace body 1 is installed on the right lower end; The fire grate 7 is installed at the bottom end of the combustion chamber 2, and the lower end of the fire grate 7 is an ash chamber 8; the smoke exhaust pipe 9 is installed on the right side of the top of the combustion chamber 2, and the smoke exhaust pipe 9 passes through the top surface of the furnace body 1 A steam chamber 10 is formed between the furnace bod...

Embodiment 2

[0016] Described steam room 10 inner device sprinkler 12, described sprinkler 12 is made of water pipe, hydraulic pump, annular water supply tank, water pipe, a plurality of shower heads; The right end of the hydraulic pump is connected to an annular water supply tank through a water pipe, and the annular water supply tank is welded on the lower end of the outer wall of the body of heater 1, and connected to a plurality of shower heads in the steam chamber 10 by the water pipe.

Embodiment 3

[0018] One layer of stainless steel metal filter screen layer 13 and two layers of activated carbon adsorption filter screen layer 14 are installed inside the exhaust pipe 9 from bottom to top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com