Multifunctional integrated cap pressing type pressure chamber in rock coupling penetration test and test method

A pressure chamber, multi-functional technology, used in permeability/surface area analysis, suspension and porous material analysis, measurement devices, etc. Achieve the effect of enhanced capacity expansion, improved safety performance, and convenient installation of temperature control equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

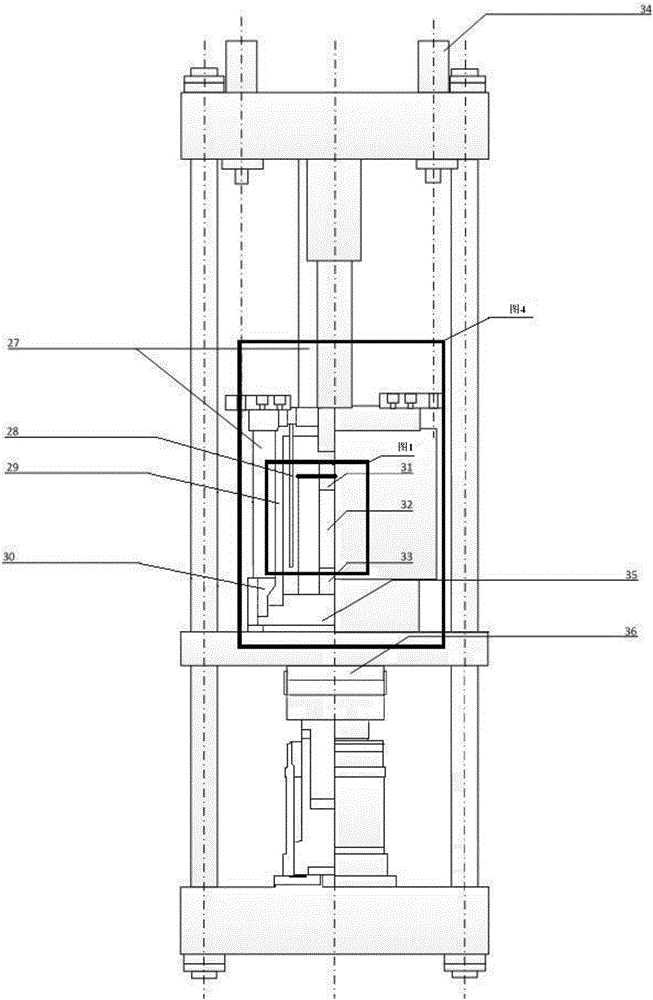

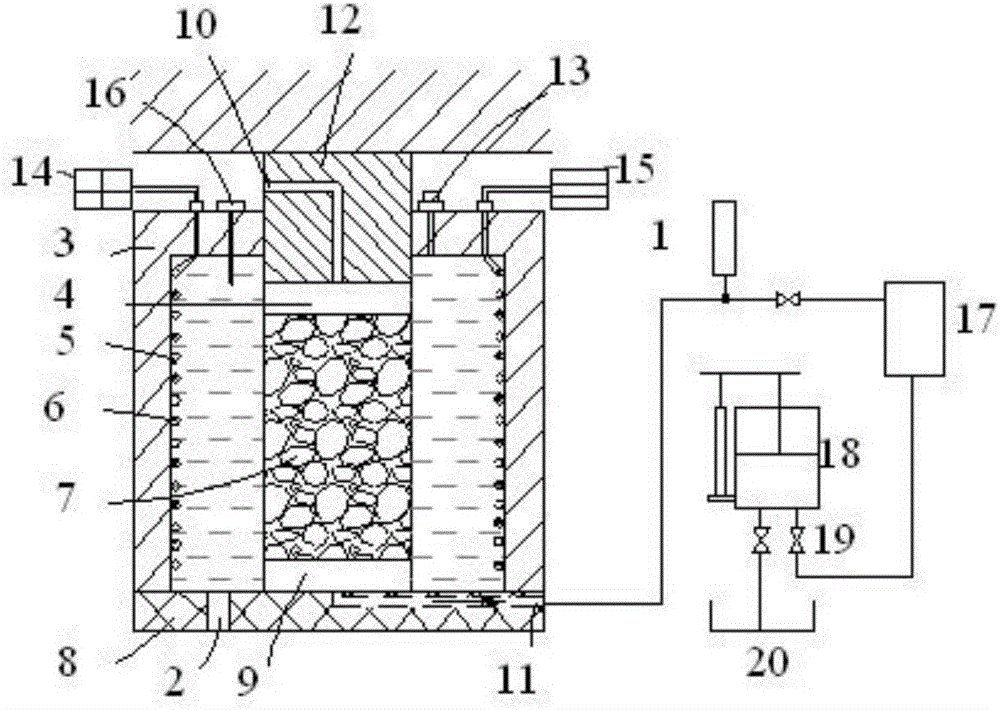

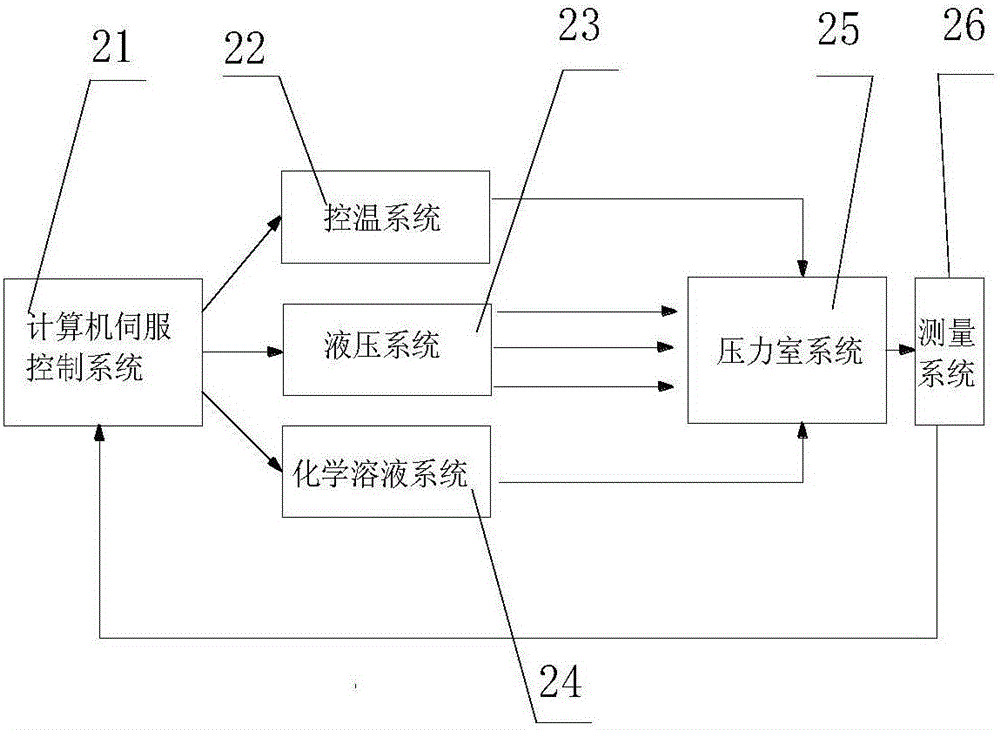

[0048] according to Figure 1 to Figure 5 , the multi-functional integral pressure cap type pressure chamber in the rock coupled permeability test, including a pressure chamber body 3, a pressure chamber base 8 (also 35) positioned at the bottom of the pressure chamber, a pressure chamber cover 39 positioned at the top of the pressure chamber, and a pressure chamber located at the pressure chamber The confining pressure oil inlet hole 2 and the seepage outlet 11 (also the permeate water outlet 46) at the bottom of the chamber, the seepage inlet 10 (also the permeate water inlet 37) near the top of the pressure chamber, are located outside the pressure chamber base and connected to the pressure chamber base The pressure chamber lock cap 44 (also 31), the lift cylinder 28 arranged on the top of the pressure chamber, the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com