Comprehensive stress acceleration test method

A comprehensive stress and accelerated test technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high cost and long test cycle, achieve small number of samples, reduce test cycle and cost, and ensure accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below:

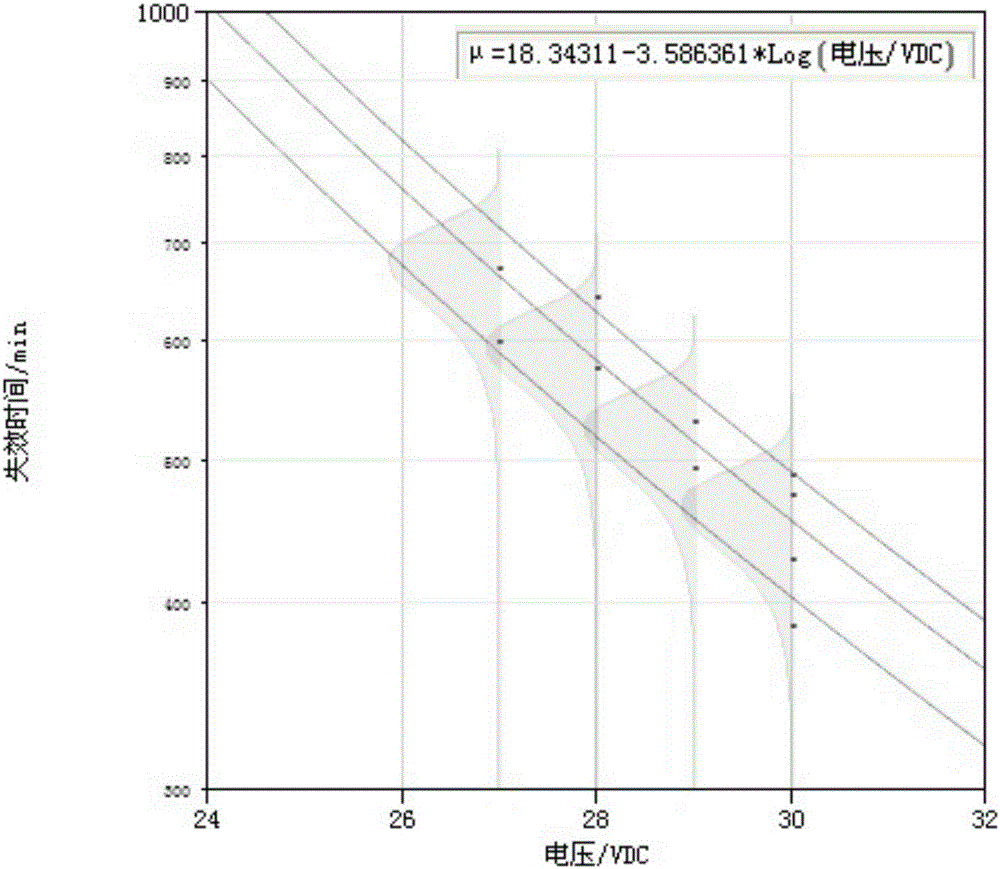

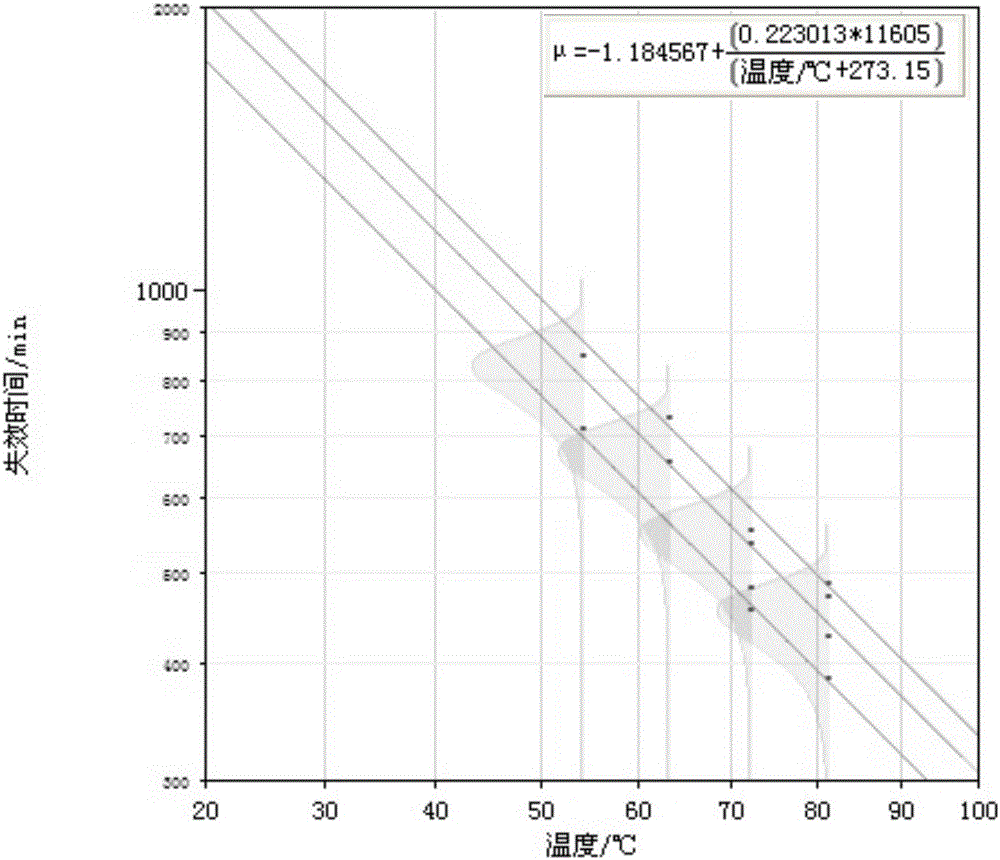

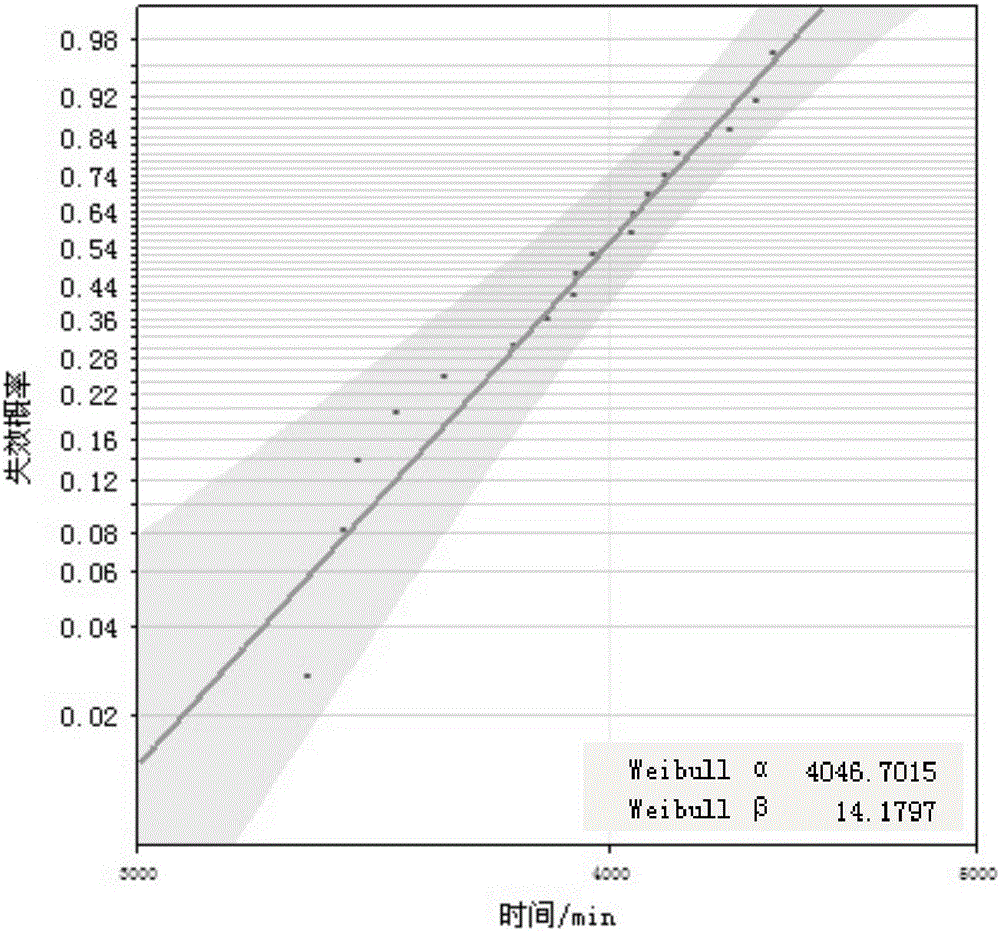

[0022] This implementation takes the simultaneous application of temperature and voltage as an example. Through the HALT test of the tested product, it is determined that its high temperature working limit is 90 °C, and through the performance limit test, its voltage limit is determined to be 32 VDC. If the stress exceeds these limit levels , which will lead to changes in the failure mechanism. In this implementation, the two stress levels are 4 test stress levels, so the test samples are divided into 7 groups, and the number of samples in each group varies from 2 to 4. According to the orthogonal test table , apply temperature-voltage comprehensive stress to each group of samples until all the tested samples in each group of samples fail, and record the failure time. The specific grouping and failure time (unit: min) are shown in the following table:

[0023]

[0024] the temperature S A =81℃ unchanged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com