Accumulating type shield grid MOSFET integrating schottky diodes

A schottky diode, accumulation type technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of large leakage, complicated process steps, etc., achieve small on-resistance, reduce process steps, and reduce conduction voltage drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

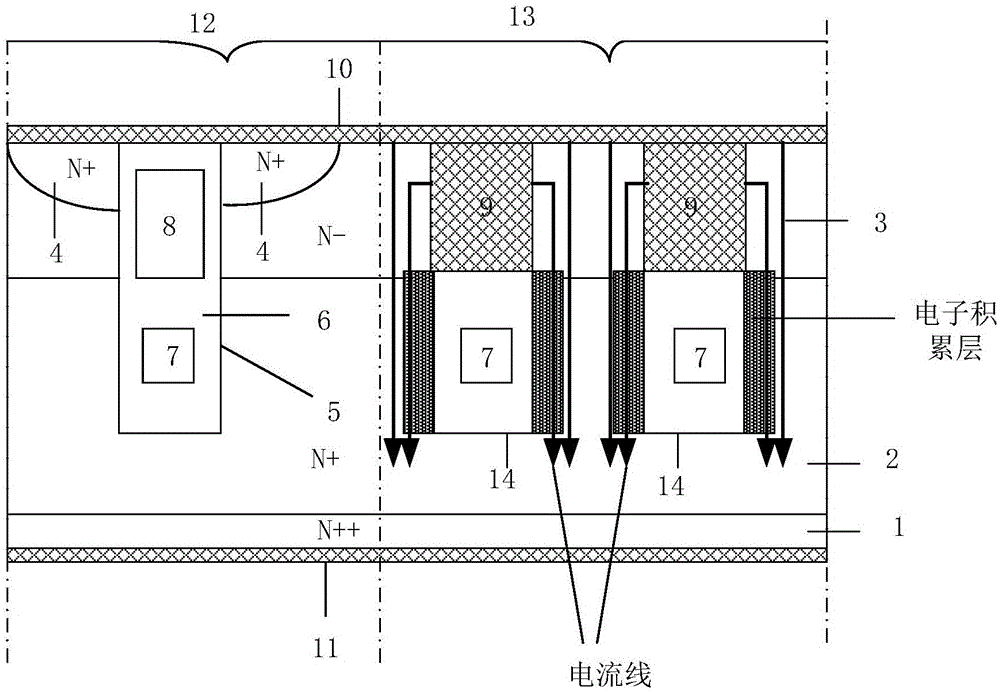

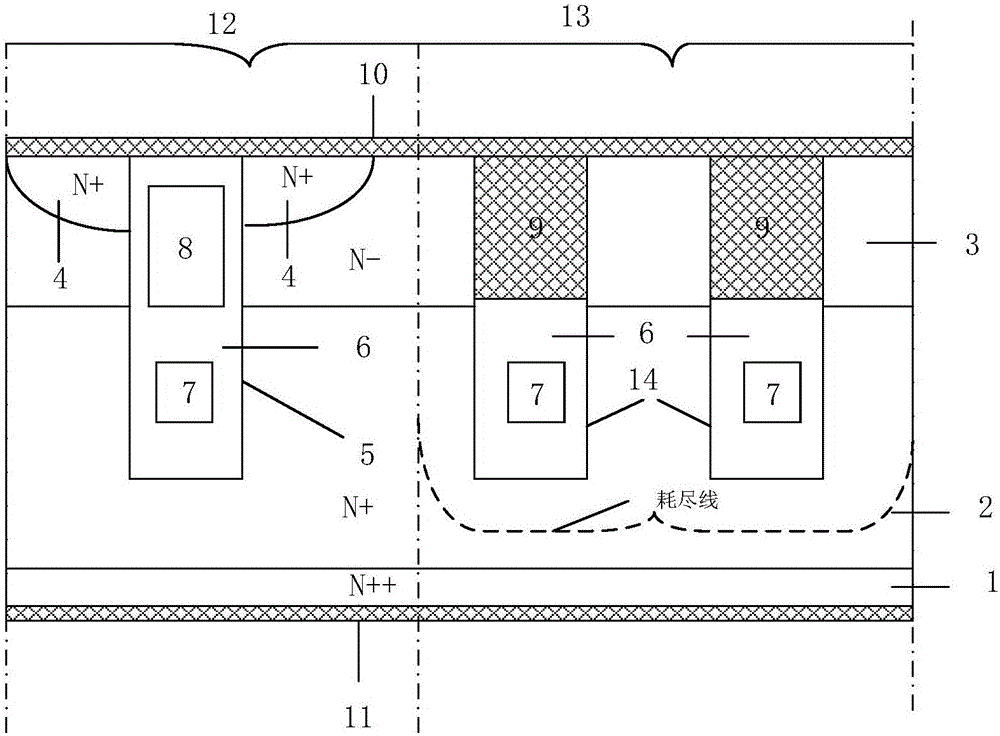

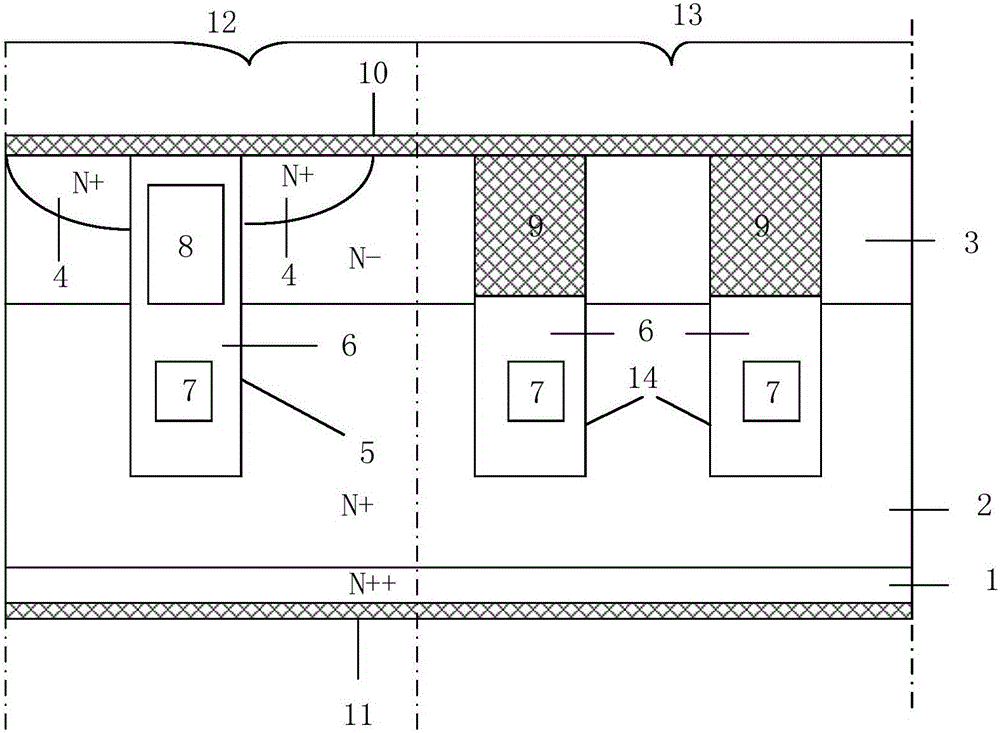

[0018] An accumulation-type shielded gate MOSFET integrating Schottky diodes according to the present invention, such as figure 1 As shown, it includes a MOSFET region 12 and a Schottky region 13; the MOSFET region 12 and the Schottky region 13 both include a first metal layer 11, an N++ type heavily doped substrate 1, an N+ type drift region 2, N-type doped region 3 and second metal layer 10; the N-type doped region 3 of the MOSFET region 12 has a first groove 5 and an N+ type heavily doped region 4; the N+ The upper surface of the type heavily doped region 4 is in contact with the second metal layer 10; the first groove 5 is located between the N+ type heavily doped region 4, and the lower end of the first groove 5 extends into the N+ type drift region 2; The upper surface of the first groove 5 is in contact with the second metal layer 10, the first groove 5 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com