Exhaust gas post treatment system

An exhaust gas post-treatment and exhaust gas technology, which is applied in exhaust gas treatment, exhaust devices, mechanical equipment, etc., can solve the problems of passive regeneration of unaided filter matrix, large heat loss, etc., to reduce the total mass and improve the starting performance. , the effect of reducing heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

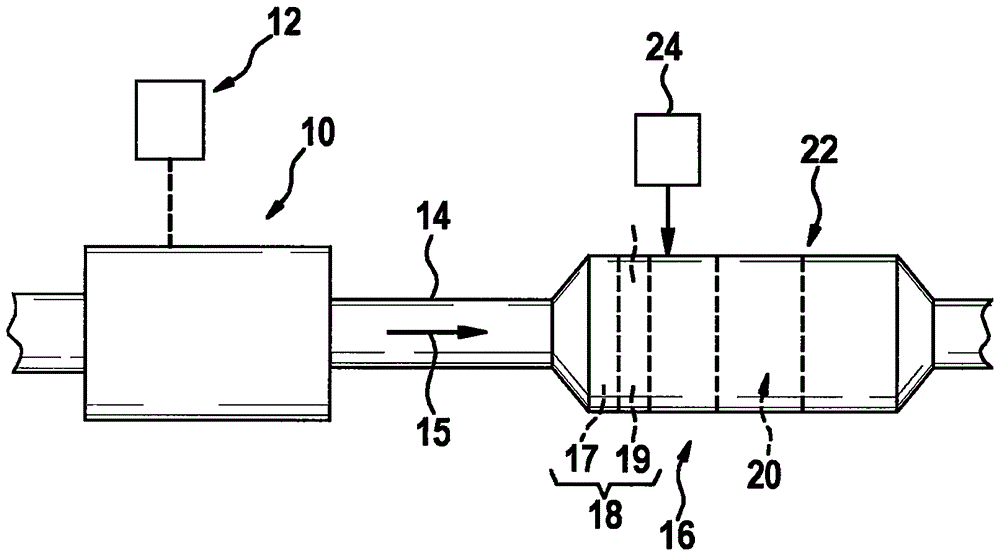

[0041] exist figure 1 The internal combustion engine is marked with the reference numeral 10 in FIG. 2 , which is controlled by a schematically shown control unit 12 via signal lines. Exhaust gases are discharged via an exhaust line 14 along a flow path 15 in which an exhaust gas aftertreatment system 16 is arranged. Exhaust gas aftertreatment system 16 is included in figure 1 Only the particle filter 17 and the device 19 with catalytic oxidation function are shown in a simplified manner, which can be combined to form a particle filter 18 with catalytic oxidation function.

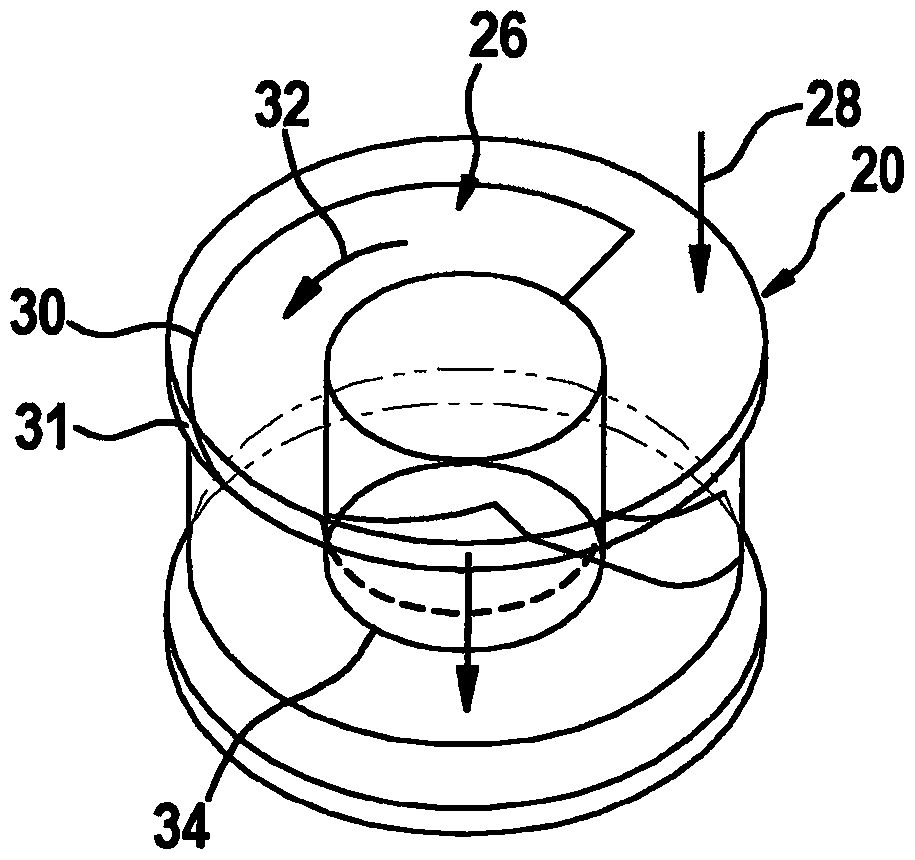

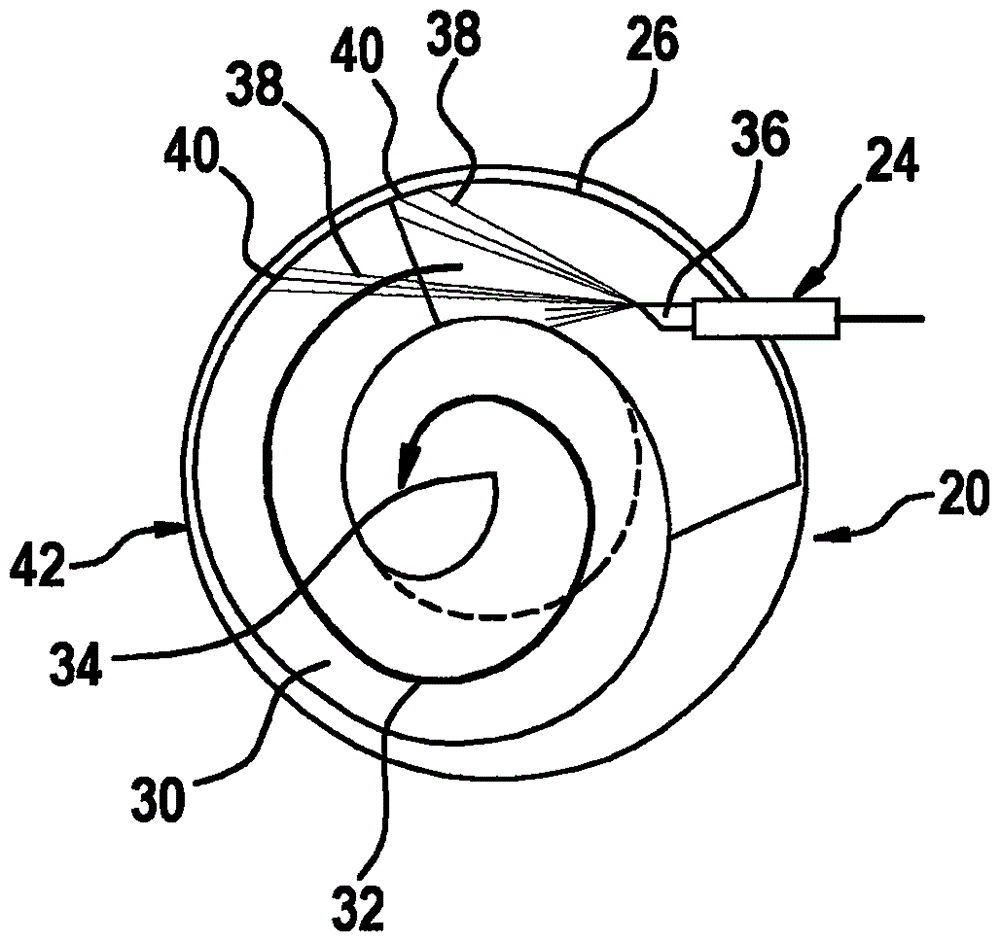

[0042] At least one mixing chamber 20 can also be combined with the particle filter 18 with catalytic oxidation function to form a structural unit 22 . On the one hand, particles can be filtered out of the exhaust gas flowing in the exhaust pipe 14 by means of the catalytic particle filter 18 and can also be activated at the catalytic converter integrated in the catalytic particle filter 18 Catalytic ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com