Air-cooled engine and engine working machine

An engine, air-cooled technology, used in engine components, engine cooling, machine/engine, etc., to solve problems such as appearance defects, ablation, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

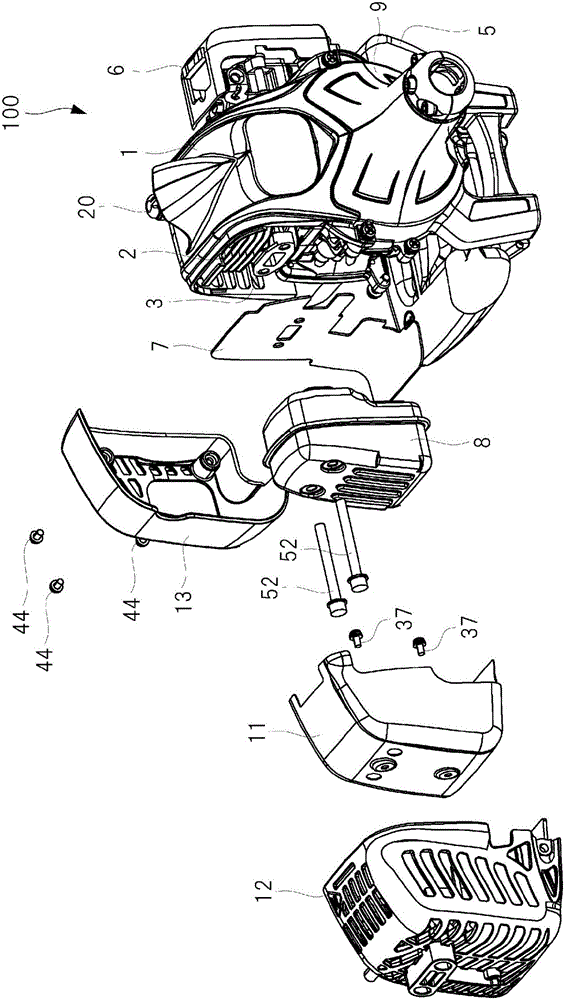

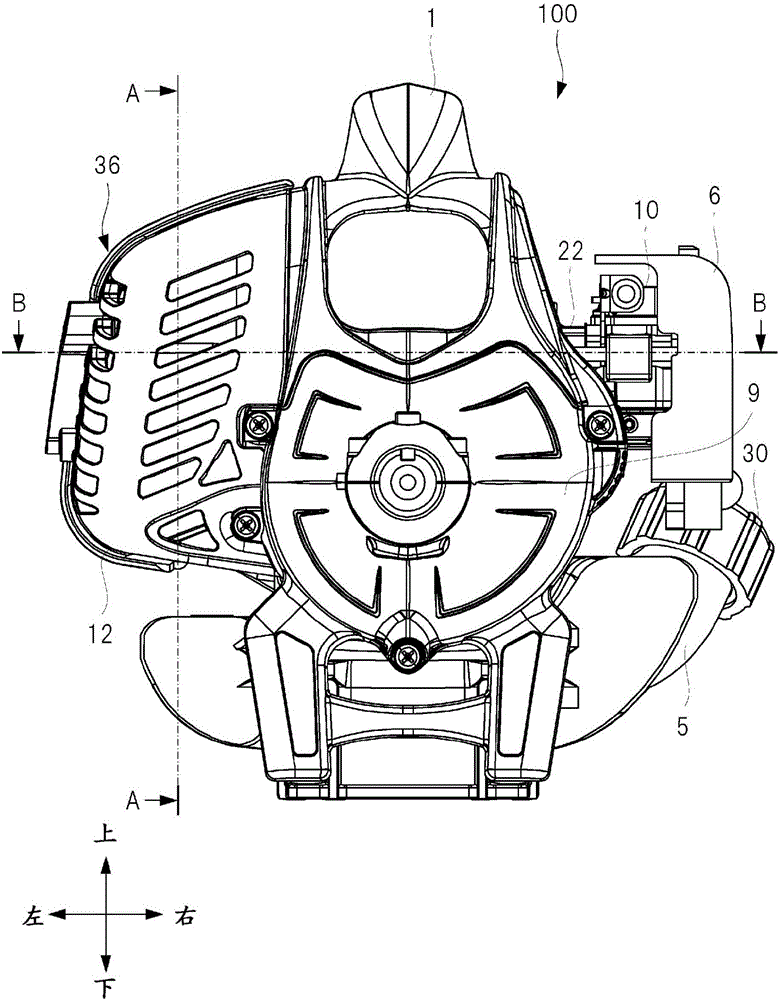

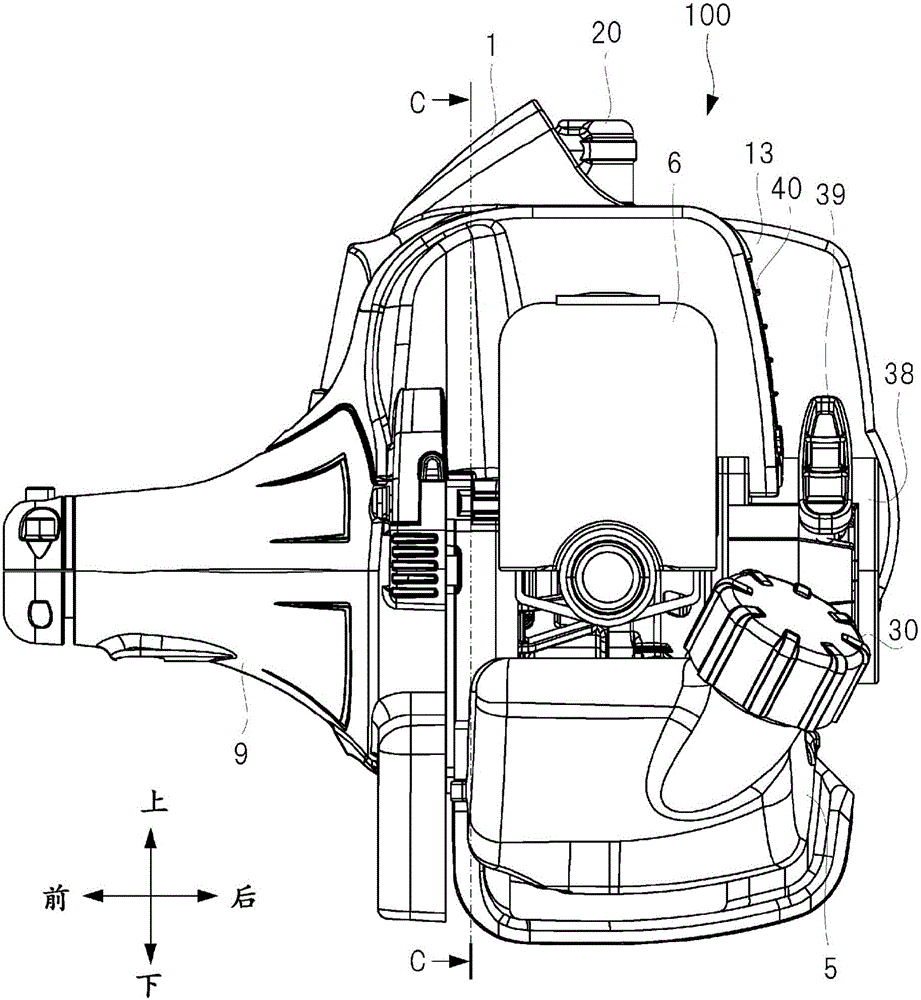

[0026] The structure of an air-cooled engine (engine) as an embodiment of the present invention will be described. Herein, the air-cooled engine includes a two-stroke engine main body having a cylinder block, a crankcase, and the like, and a block head that covers the cylinder block and the like. In the engine main body, a cooling fan is fixed to the drive shaft, and the cylinder block is cooled in the block head by cooling air generated by the rotation of the cooling fan. Further, in the cylinder, a plurality of cooling fins are formed on the outer surface of the cylinder portion formed in a substantially cylindrical shape, and the combustion chamber is formed inside the cylinder portion.

[0027] This engine is suitable for a portable work machine carried by an operator, such as a brush cutter and a blower, and the engine having the above structure is installed in the engine work machine. Therefore, actually, a speed reducer, etc. for driving the engine working machine are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com