Gas-liquid distribution disk for hydrogenation reactor

A technology for hydrogenation reactors and gas-liquid distribution, applied in chemical instruments and methods, hydrocarbon oil cracking, petroleum industry, etc., can solve the problems of concentration, uneven distribution, low reactor efficiency, etc., to avoid uneven distribution, The material is evenly distributed and the effect of improving the splashing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

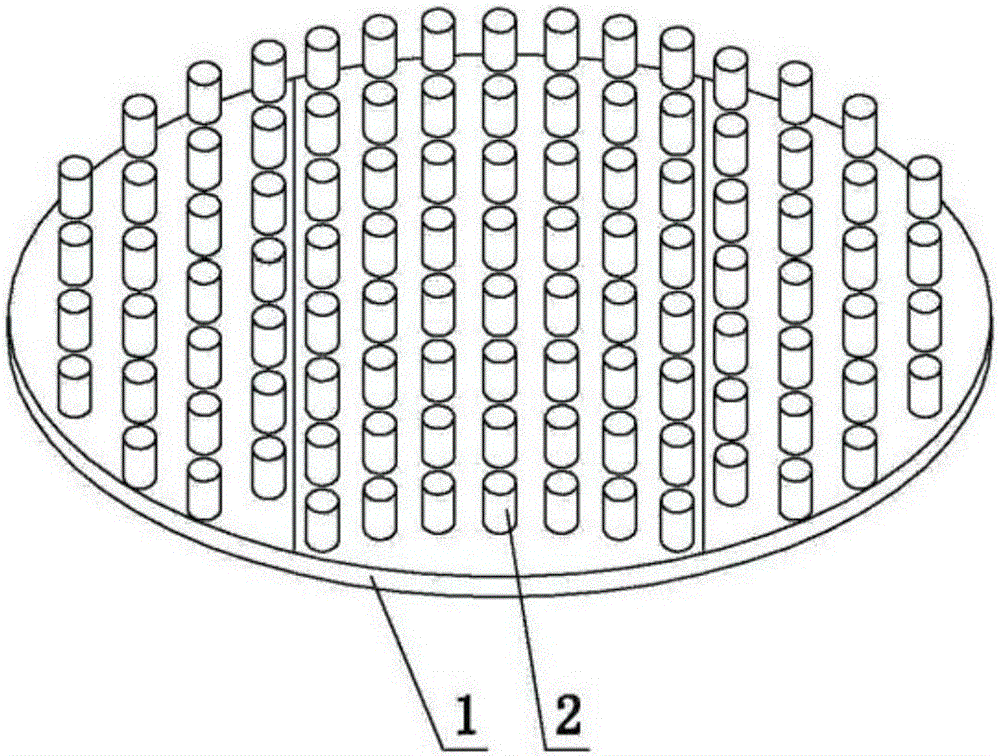

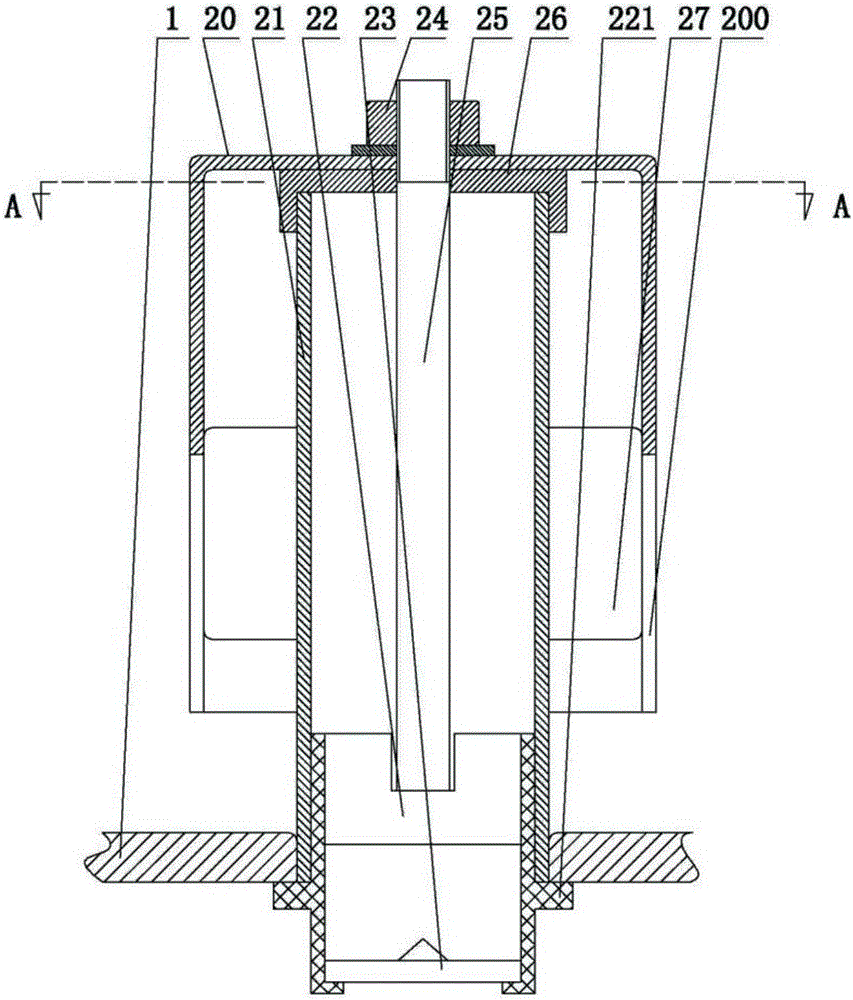

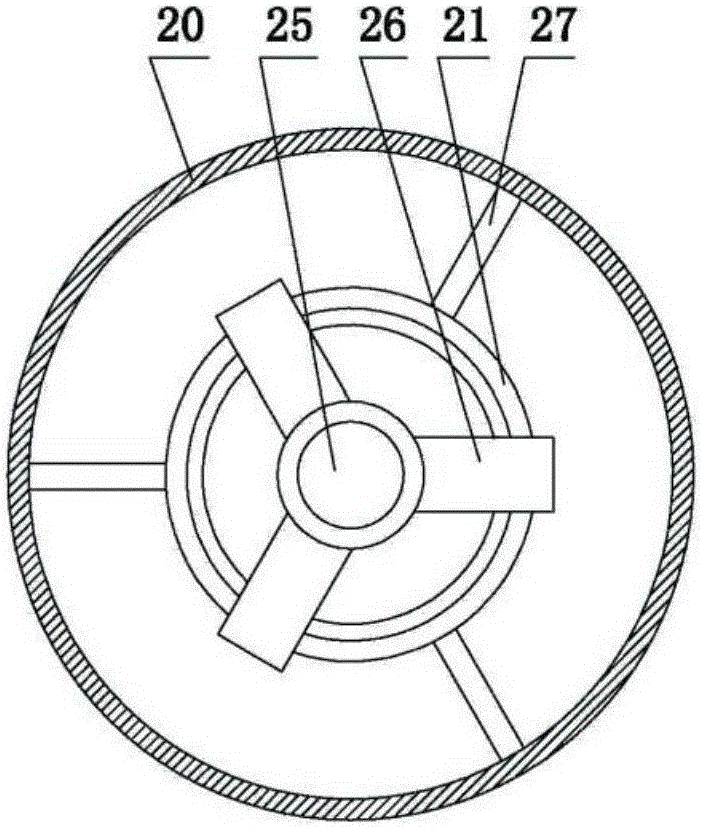

[0017] figure 1 It is a structural schematic diagram of the present invention, figure 2 is a schematic diagram of the allocator structure, image 3 It is the A-A sectional view of the distributor, Figure 4 It is a schematic diagram of the broken flow plate, Figure 5 yes Figure 4 Bottom view of the broken flow plate shown, Image 6 is another schematic diagram of the broken flow plate, Figure 7 It is a schematic diagram of the structure of a multi-layer broken flow plate. It can be seen from the figure that the gas-liquid distribution plate includes a plate 1 on which a plurality of distributors 2 are arranged. The distributor 2 is composed of a bubble cap 20, a central tube 21, a bubble cap support 26, a clamping plate 22, a broken flow plate 23, a bubble cap auxiliary positioning plate 27, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com