Perovskite catalytic persulfate, and preparation method and application thereof

A technology of persulfate and perovskite, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of low self-use rate of rare earths, and achieve the effect of ensuring water quality safety and improving water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

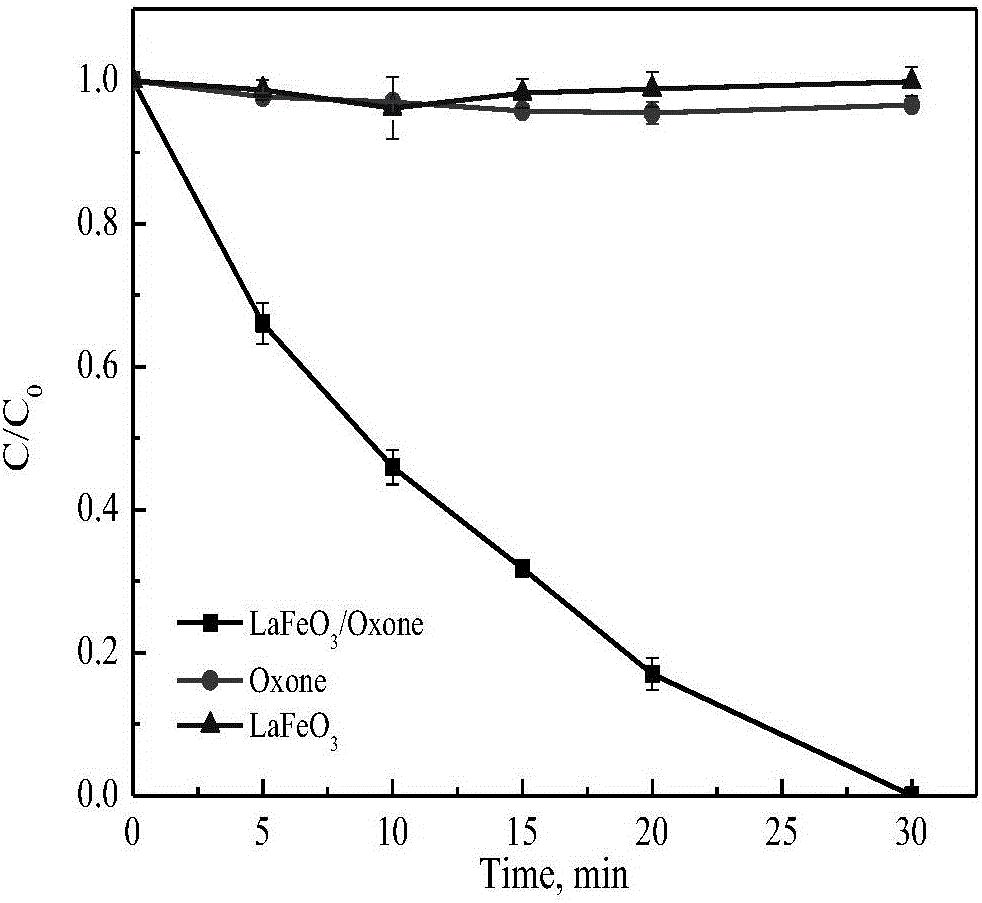

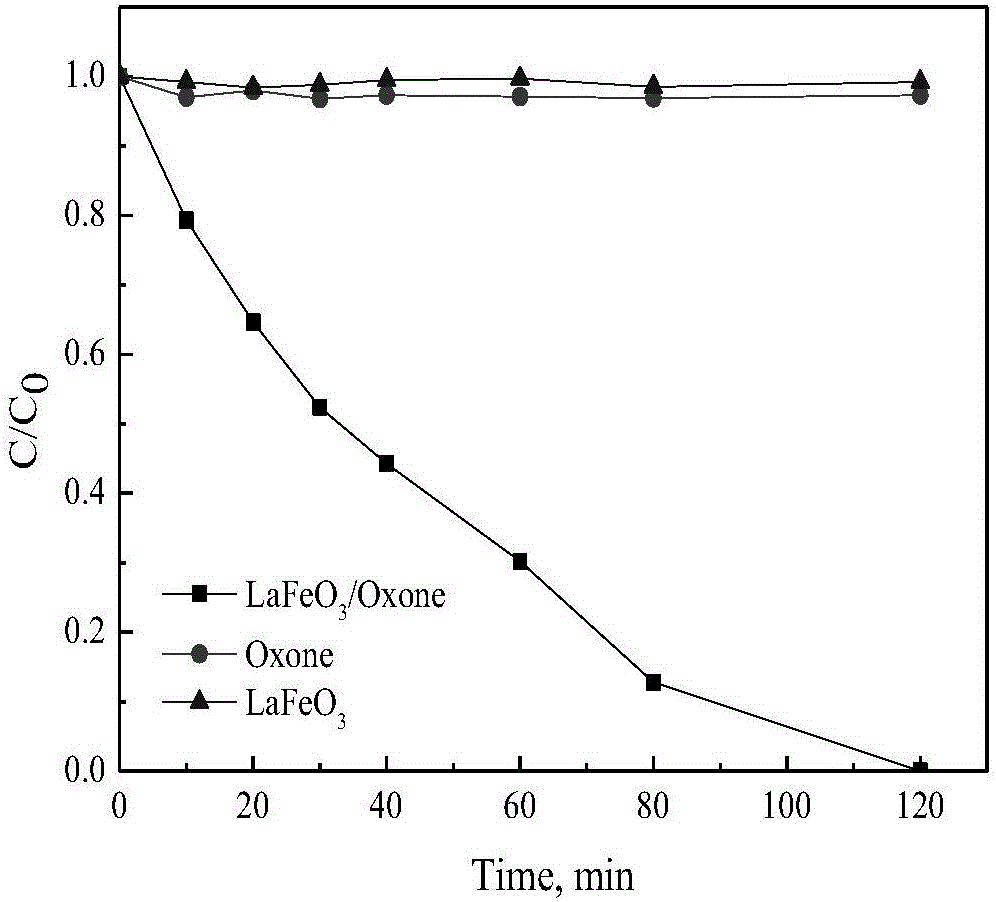

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

[0025] The preparation method of perovskite catalyzed persulfate of the present invention comprises the following steps: (1) according to the molar ratio, be La:Co:CA=1:1:2 and take appropriate amount of La (NO 3 ) 3 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O and C 6 h 8 o 7 ·H 2 O, add a small amount of water to dissolve, and stir at room temperature for 12 hours; (2) place the prepared precursor solution in a water bath heating pot at 80°C for 12 hours to make it completely gel; (3) at 80°C Place it in a vacuum drying oven for 12 hours to dry it; (4) raise the temperature of the muffle furnace to 500°C at a rate of 5°C / min, and calcinate for 3h to obtain the catalyst LaFeO 3 ; (5) the calcined LaFeO 3 The powder is ground to uniform fine particles for later use.

[0026] Catalyzed persulfate salt water treatment method of the present invention: the LaFeO of gained 3 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com