Small-particle ore X fluorescence dressing machine based on belt transmission

A mineral concentrator and small particle technology, which is applied in the field of fluorescent mineral concentrators, can solve the problems of poor selection and selection effects, and achieve the effects of fast execution, reduced radiation leakage, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with accompanying drawing:

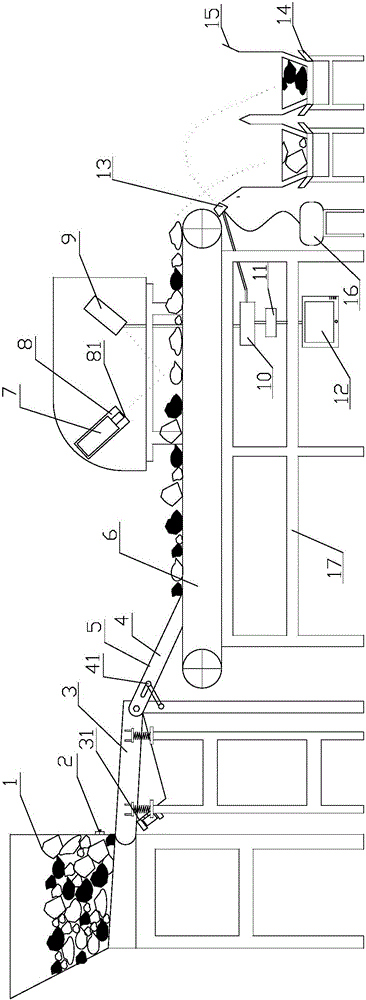

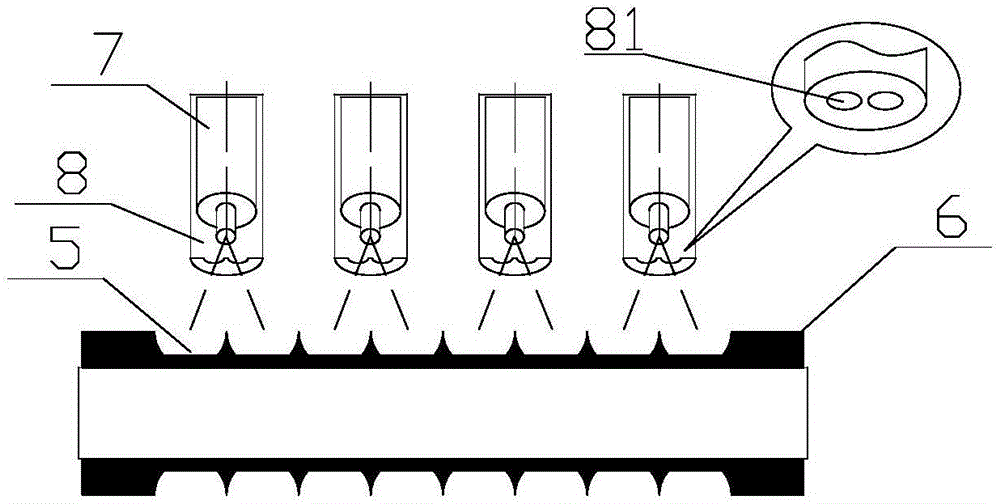

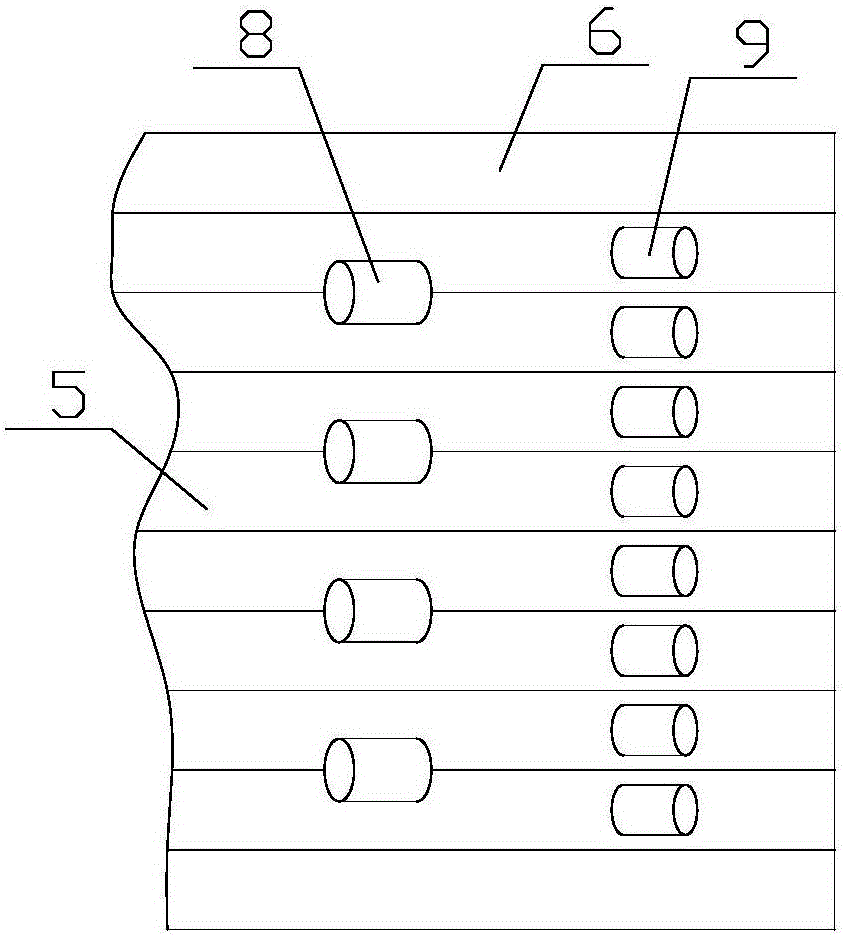

[0026] A small particle ore X-fluorescent concentrator based on belt transmission includes a feeding bin 1, a vibrating feeder 3, a feeding slide 4, a scanning conveyor belt 6, an X-ray source 7, an X-ray source protective cover 8, and an X-ray fluorescent Receiver 9, signal processing device 10, industrial computer 11, display 12, air separation device 13, separation conveyor belt 14, separation feeding protection 15, air storage tank 16, frame 17. The vibrating feeder 3 is used to feed the material in the feeding bin 1 into the scanning conveyor belt 6. An X-ray source 7 and an X-fluorescence receiver 9 are arranged above the scanning conveyor belt 6, and an air separation device 13 is arranged at the end to feed the material Be divided into the path of free fall and the path away from free fall and fall into the material separation conveying belt 14 respectively.

[0027] A g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com