Online dynamic vision laser precise processing method

A technology of precision machining and laser machining, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem that cannot meet the requirements of high-precision laser precision machining of pipeline-type moving workpieces, and the sensor accuracy and sensitivity have high requirements and influence. Processing efficiency and other issues, to achieve the effect of improving production and processing efficiency, increasing production capacity, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is a detailed description of the embodiments of the present invention. In order to make the technical means, features and effects of the present invention easy to understand, the implementation and specific operation process of this embodiment of the present invention will be described in conjunction with the diagrams, but the protection of the present invention The scope is not limited to the examples described below.

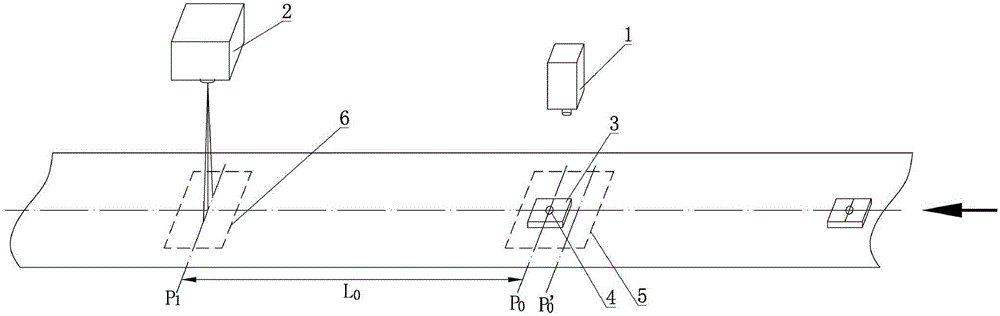

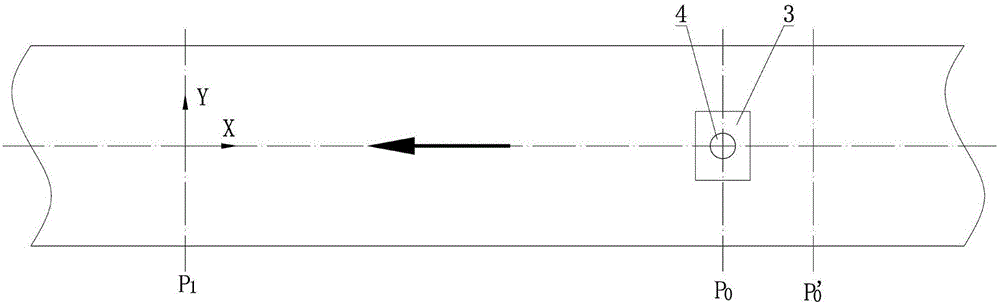

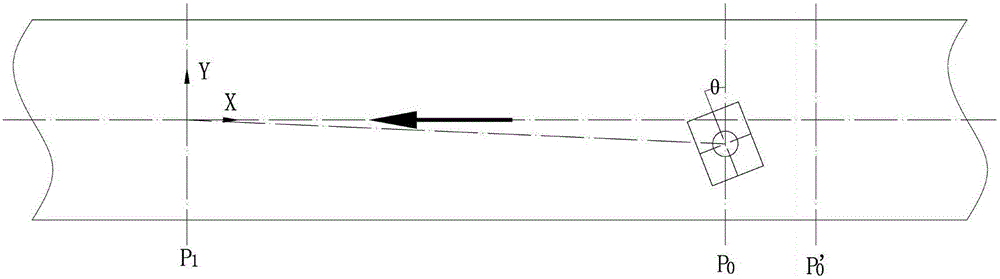

[0029] An on-line dynamic visual laser precision machining method of the present invention is to collect the position and time information of the workpiece in real time through the CCD high-speed camera when the workpiece is moving at an average speed on the assembly line, and calculate the workpiece from the designated detection position of the CCD high-speed camera to the The time required by the laser processing center. When the workpiece reaches this time point, the laser is triggered to irradiate the surface of the workpiece, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com