Novel box girder bottom die system

A bottom form and box girder technology, which is applied in ceramic forming machines, auxiliary forming equipment, lifting devices, etc., can solve the problems that the bottom formwork cannot be moved effectively and cannot be directly applied to the construction of ultra-high twisted body segment box girder, etc. The effect of convenient processing and use, shortening construction period and reducing construction strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

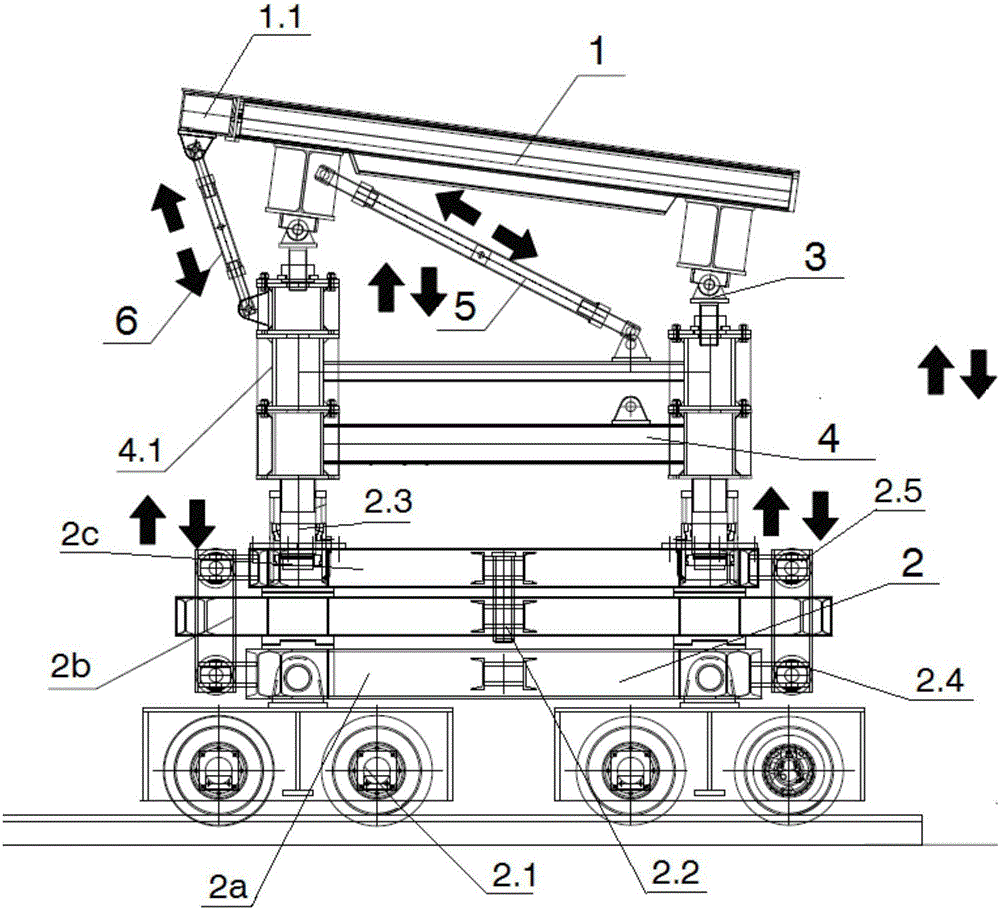

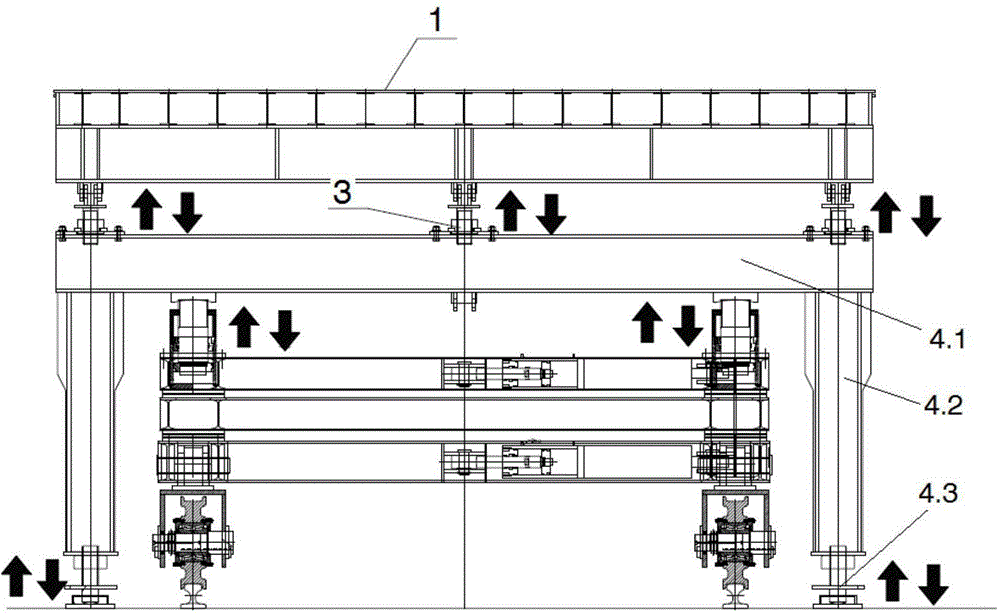

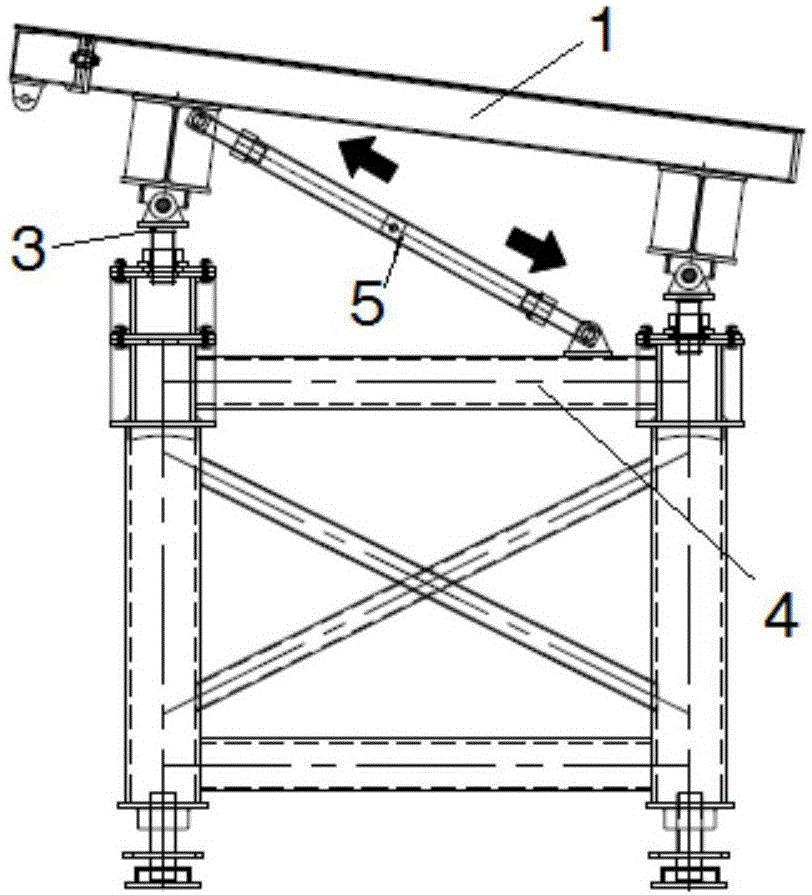

[0034] by Figure 1 to Figure 2 As shown in a new type of box girder bottom mold system, the present invention includes a bottom mold trolley 2 installed on a preset track; the bottom mold trolley 2 is connected with a bottom mold 1; the bottom mold trolley 2 is provided with The hydraulic jacking cylinder 2.3 for lifting the bottom mold, the hydraulic horizontal moving cylinder 2.4 for translating the bottom mold and the hydraulic rotating cylinder 2.5 for rotating the bottom mold; a bottom support 4 is provided between the bottom mold trolley 2 and the bottom mold 1. ; Between the bottom sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com