Plastic-coated automatic powder feeding device for large-diameter steel pipes

A powder feeding device and large-diameter technology are applied in the field of automatic powder feeding devices for inner coating of steel pipes, which can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

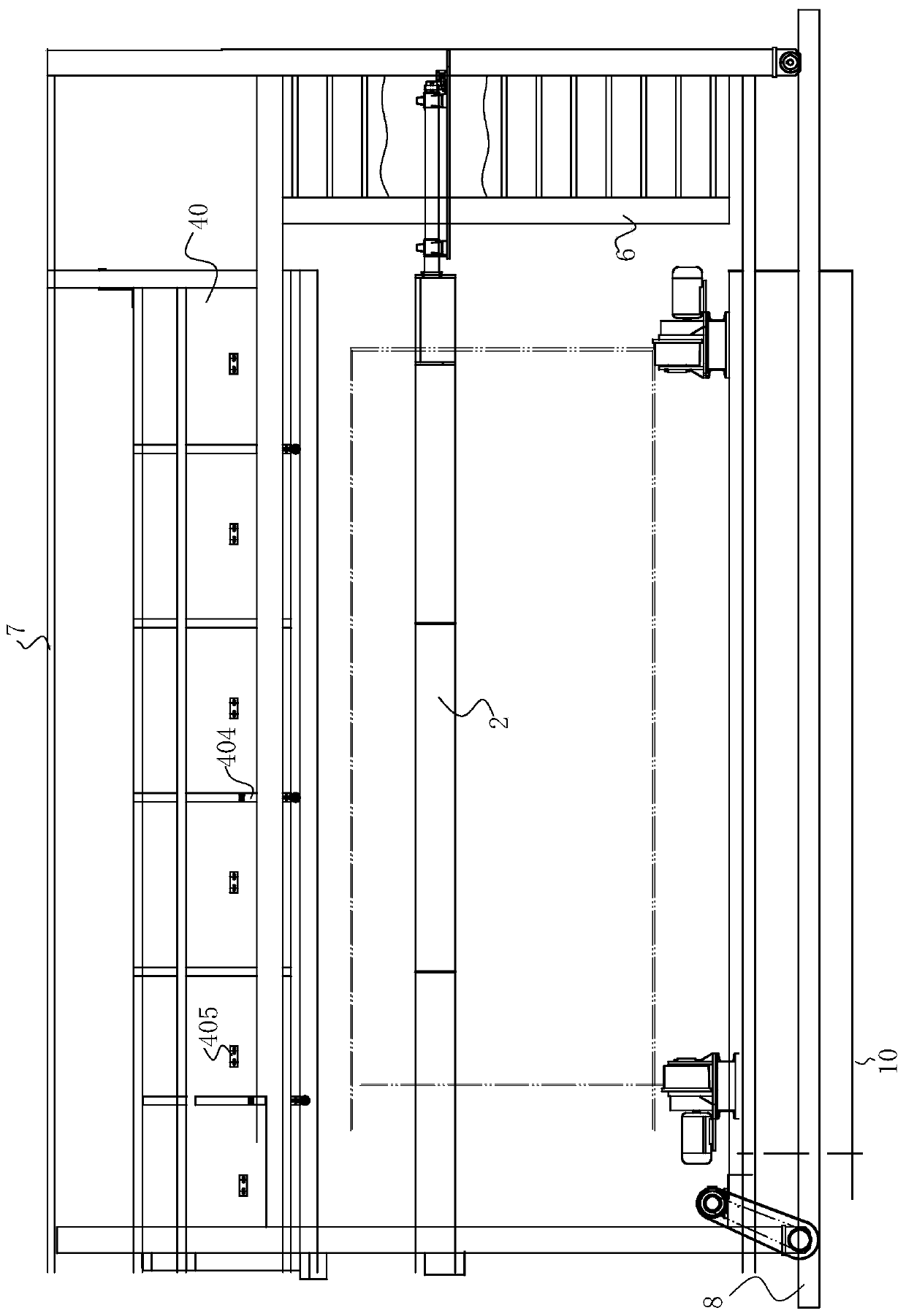

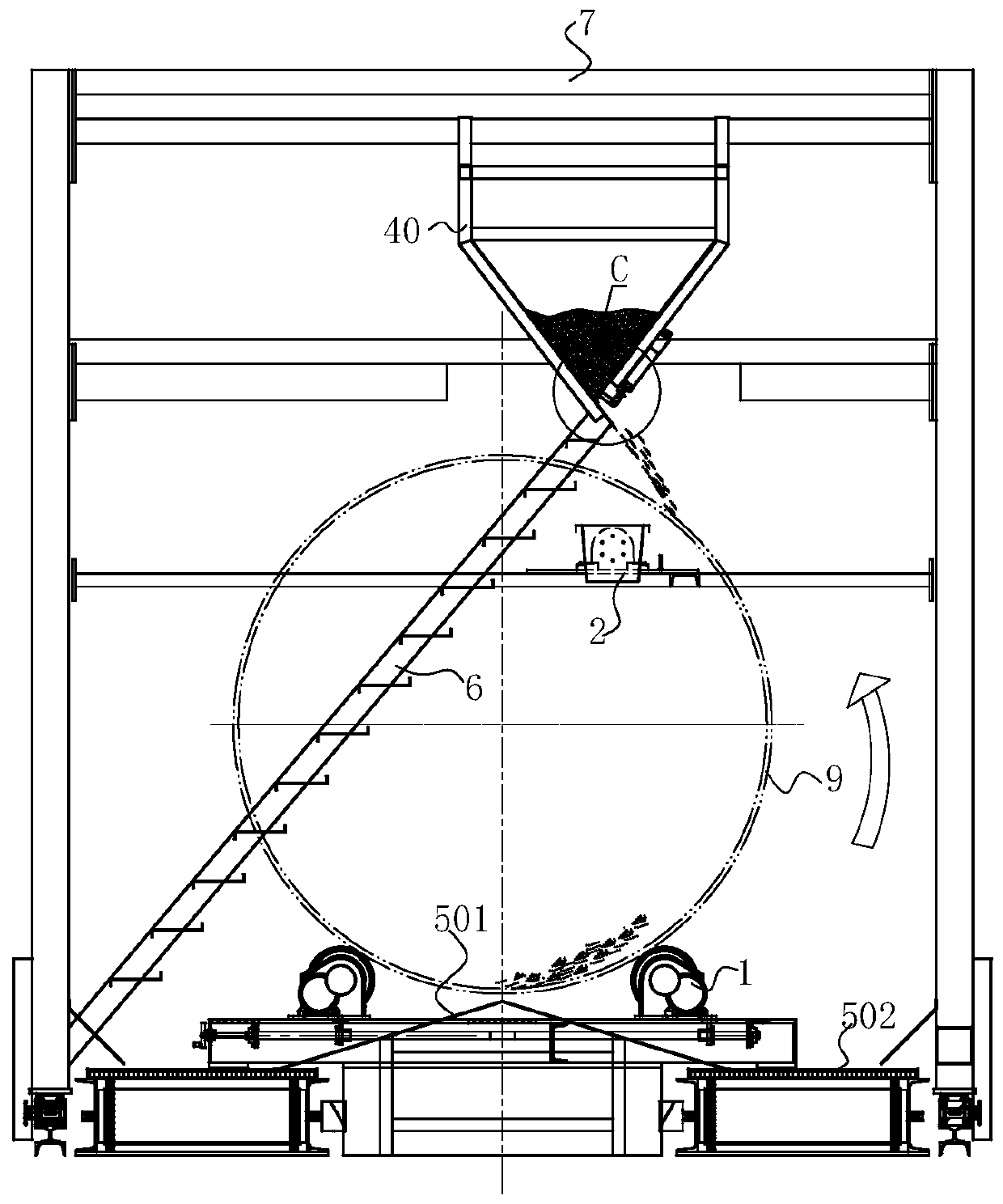

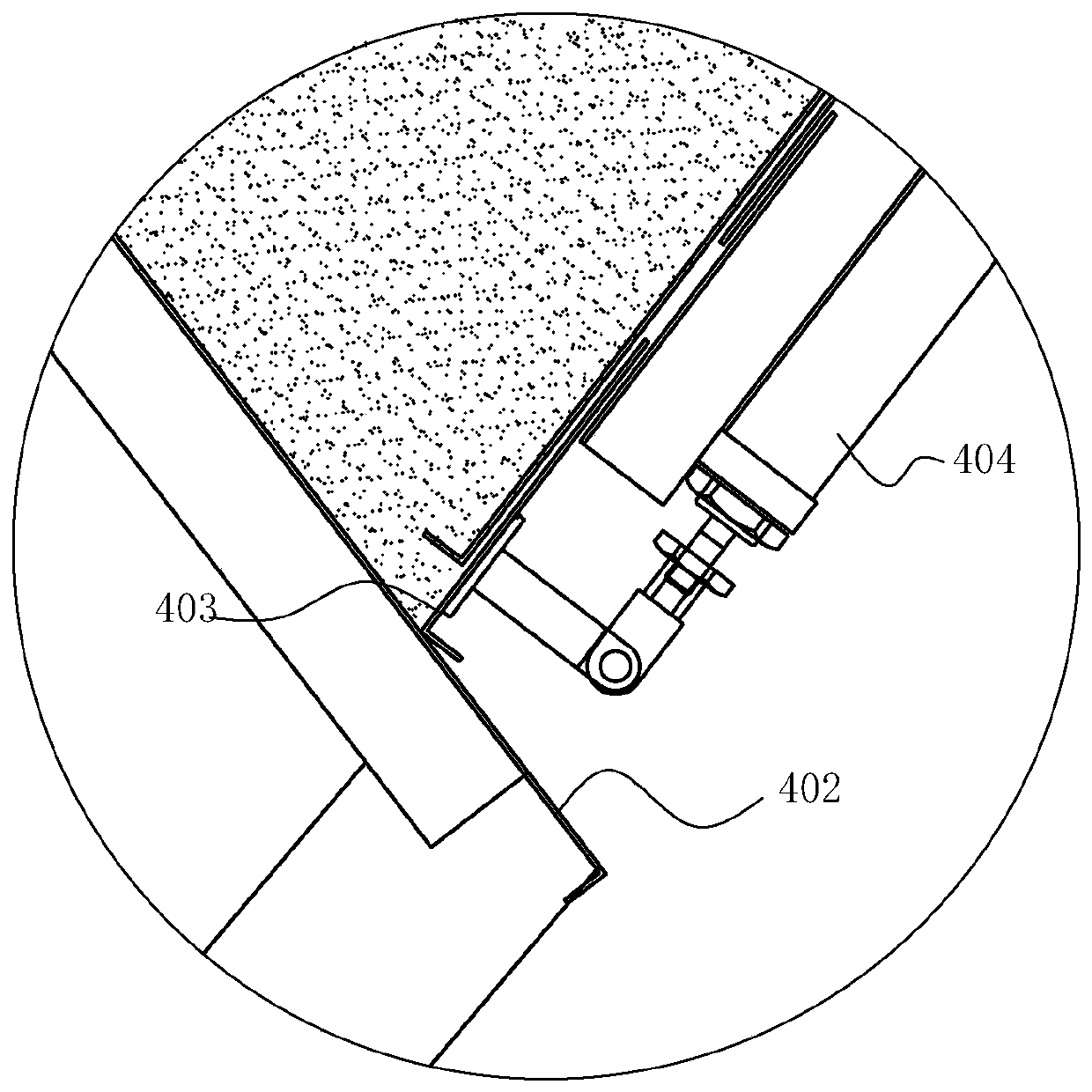

[0030] combine figure 1 , figure 2 , Figure 6 as well as Figure 7 As shown, a large-diameter steel pipe plastic coating equipment includes an underframe 10, and the underframe 10 is provided with a steel pipe rotating device 1. There are two sets of steel pipe rotating devices 1 for supporting both ends of the steel pipe 9. Each group of steel pipe rotating devices 1 includes a support seat 105, which is installed on the chassis 10. The support seat 105 is rotatably mounted with at least two side-by-side The rollers 103, at least one roller 103 is a driving roller 103 driven by a motor 104.

[0031] Anti-slip teeth 109 are provided on the outer peripheral surface of the roller 103, and grooves for accommodating plastic powder are provided between adjacent anti-slip teeth 109. When the steel pipe 9 is coated with plastic, the temperature is generally about 280°C to 320°C. When the steel pipe 9 is in contact with the roller 103, the plastic powder on the outer surface of ...

Embodiment 2

[0046] combine Figure 8As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that there are two turning shafts 21 and two turning hoppers 22 , and one turning shaft 21 is fixedly connected to one turning hopper 22 . The overturn driving device includes two gears 25, and the two gears 25 are connected to the two turning shafts 21 respectively. The rack 24 is slidably installed on the base and meshes with two gears 25 respectively, and the cylinder 23 is connected between the rack 24 and the base. In this embodiment, one cylinder 23 can be used to control the turning of two turning hoppers 22 , and it is possible to carry out internal plastic coating for two steel pipes 9 at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com