Micropower slow-release type aeration structure and method

A slow-release, micro-dynamic technology, applied in water aeration, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of insufficient utilization of oxygen, limited promotion and application, and high operating costs. Achieve the effect of avoiding excessive sludge agglomeration, flexible installation methods, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

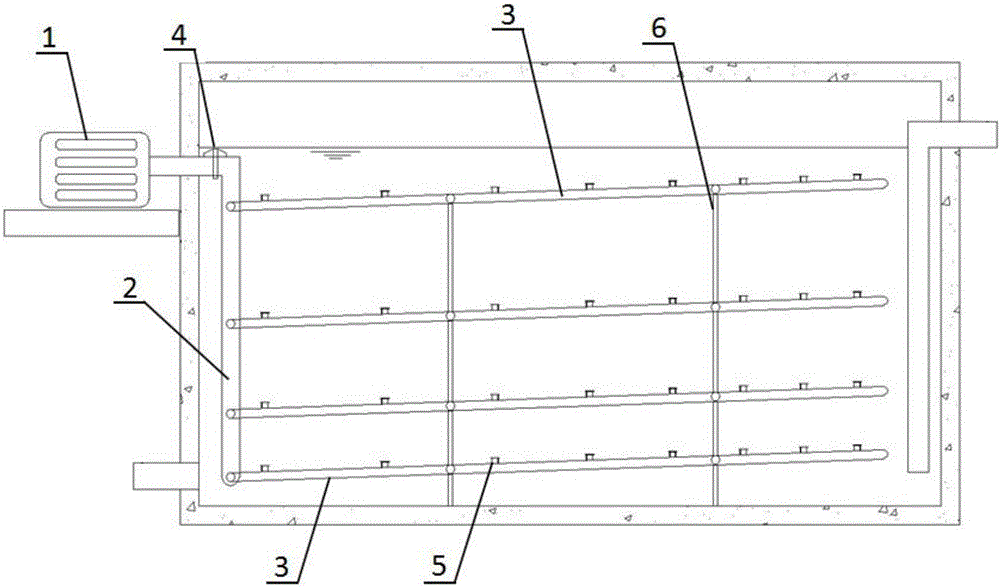

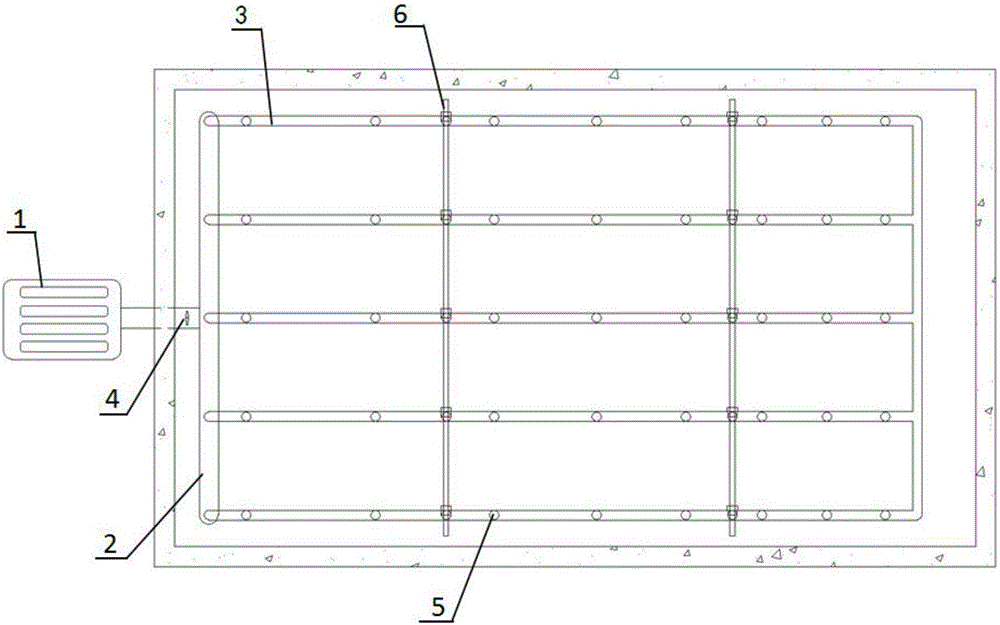

[0053] Specific embodiment 1, such as figure 1 Shown:

[0054] An optimized design of the present invention is that it is installed in a sewage treatment tank with an effective volume of 20m3, the diameter of the aeration main pipe 2 of the aeration system is 60mm, and the check valve 4 is installed. The diameter of the aeration branch pipe 3 is 10mm, and the inclination angle of 3° upwards should be taken from the horizontal when installing, and 4 layers of aeration branch pipes 3 should be installed with a distance of 150-350mm, and 5 aeration branch pipes 3 should be laid evenly on each layer. In the sewage treatment tank.

[0055] The diameter of the air aeration holes 8 on the aeration branch pipe 3 is 2-5mm. Along the air flow direction in the aeration branch pipe 3, the diameter of the aeration holes 8 gradually increases, and the spacing between the holes is 200-400mm, along the aeration branch pipe 3 The distance between the air flow directions gradually decreases. The l...

specific Embodiment 2

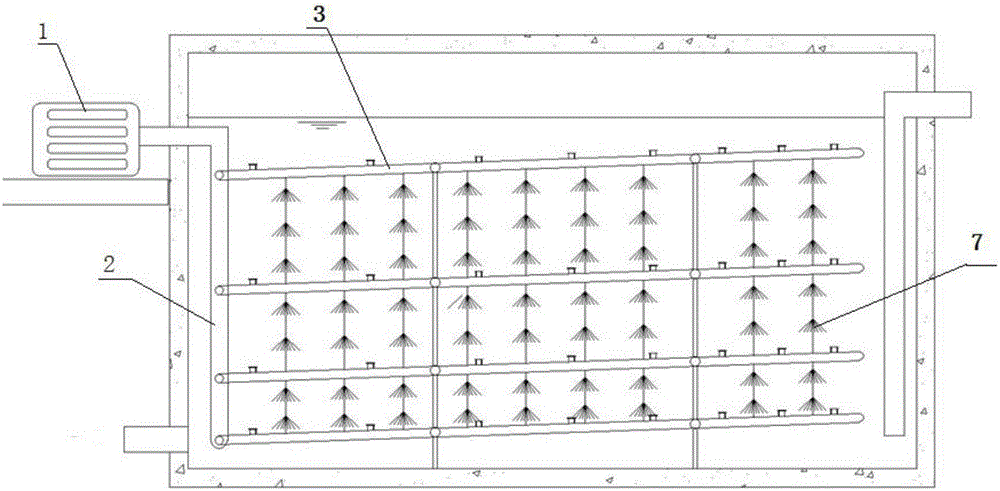

[0057] Specific embodiment 2, such as image 3 Shown:

[0058] Another optimized design of the present invention is that, installed in a sewage treatment tank with an effective volume of 50 m3, the diameter of the aeration main pipe 2 of the aeration system is set to 80 mm, and a check valve 4 is installed. The diameter of the aeration branch pipe 3 is 10mm, and the inclination angle should be 5° upward when installing. The sewage treatment tank is installed with 4 layers of aeration branch pipes 3, and the layer spacing is 150-000mm. Each layer is evenly laid with 5 aeration branch pipes 3 Distributed in the sewage treatment tank; and the aeration branch pipe 3 is used as the filler 7 support, and the filler 7 is installed on the aeration branch pipe 3.

[0059] To cooperate with the realization of the method of the present invention, based on the same inventive concept, such as Image 6 As shown, the present invention also provides a micro-dynamic slow-release aeration method, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com