Multifunctional composite filter core

A composite filter element, multi-functional technology, applied in filtration separation, filtration treatment, membrane filter and other directions, can solve the problems of large occupied space, complex assembly, poor purification effect, etc., to reduce the overall size, improve the filtration efficiency, save filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

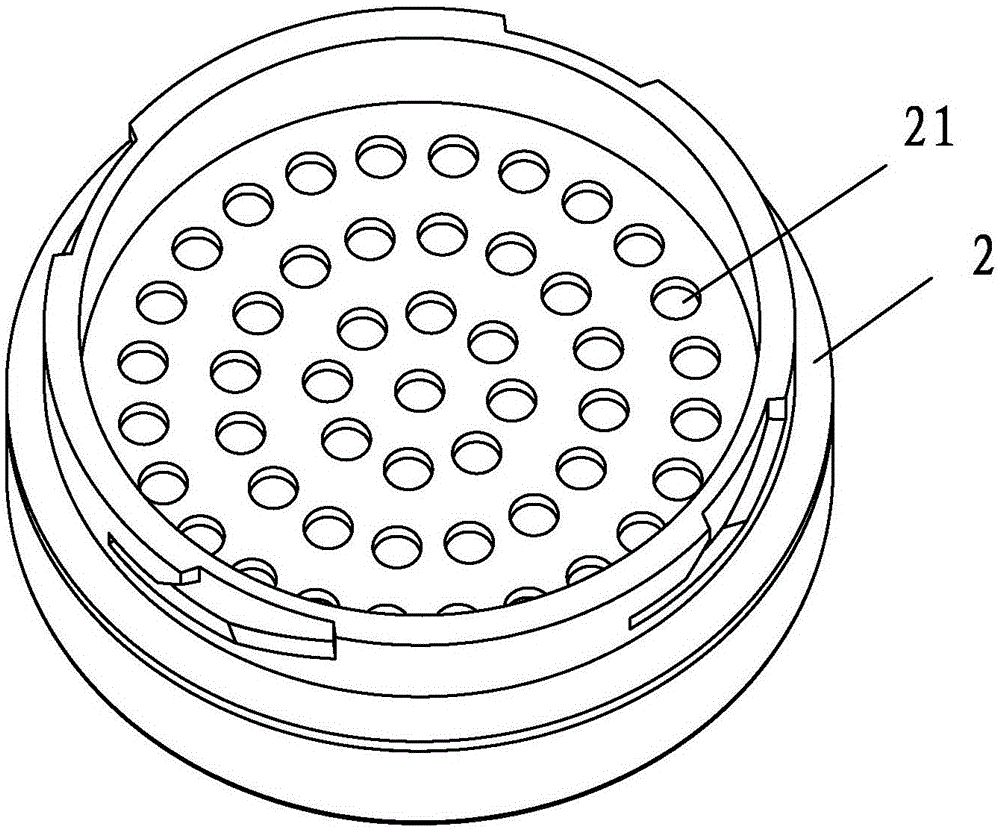

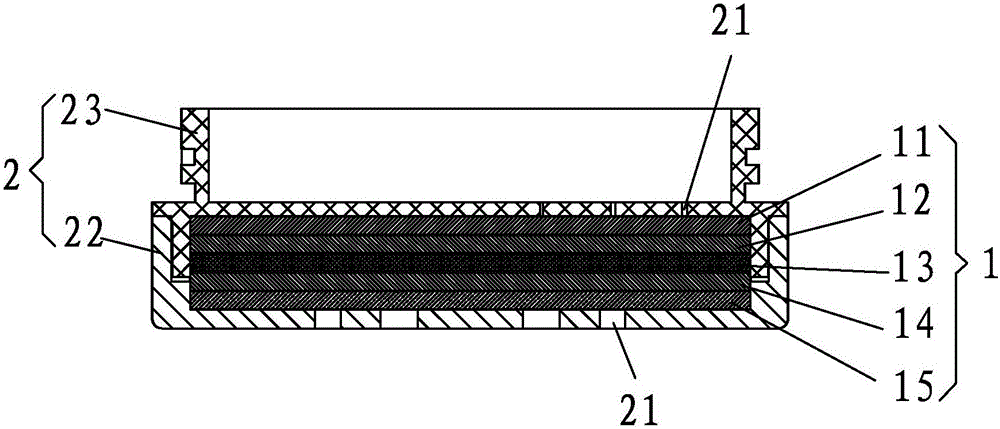

[0067] Such as figure 1 and figure 2 As shown, this embodiment also includes a filter housing 2, the filter housing 2 can be made of non-filtering materials such as rubber into a cover shape, and the top of the filter housing 2 is provided with a bayonet structure. When in use, the filter housing 2 is connected through the bayonet structure on the container body. The bottom of the filter housing 2 is provided with an accommodating cavity, and various filter materials are arranged in the accommodating cavity, and the upper and lower shell walls of the filter housing 2 are respectively provided with filter holes 21 for the media to be filtered to pass through. Specifically, the filter housing 2 includes an outer shell 22 and an inner shell 23 that are interlocked with each other inside and outside. The lower end of the inner shell 23 extends into the outer shell 22 and is assembled with the outer shell 22 in a detachable manner such as tight fitting or fitting. . The upper e...

Embodiment 2

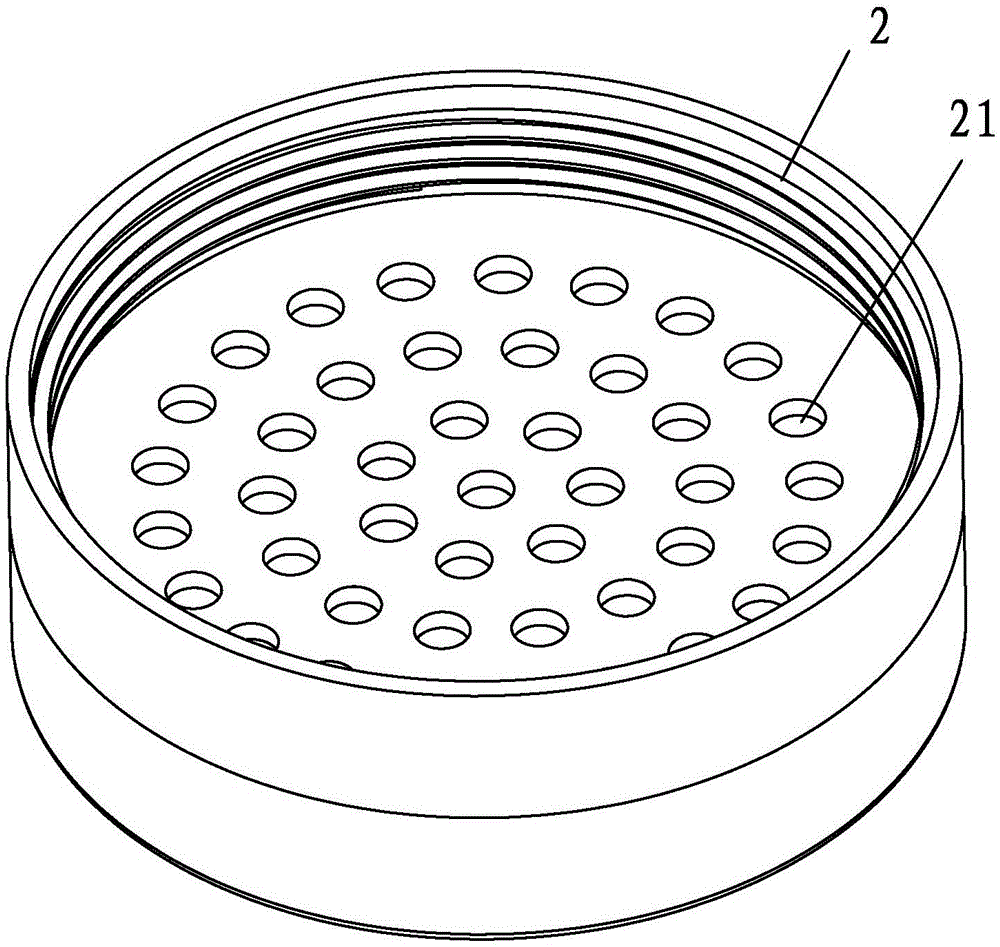

[0073] Such as image 3 and Figure 4 As shown, the main difference between this embodiment and the first embodiment is that the top of the filter housing 2 is provided with a screw structure, and when in use, the filter housing 2 is connected to the container body through the screw structure.

[0074] The first layer of filter material 11, the second layer of filter material 12, the third layer of filter material 13, the fourth layer of filter material 14, and the fifth layer of filter material 15 from top to bottom in the filter housing 2 are non-woven fabric, ion Exchange fiber membrane, activated carbon fiber membrane, ion exchange fiber membrane and non-woven fabric.

Embodiment 3

[0076] Such as Figure 5 and Figure 6 As shown, the main difference between the present embodiment and the first embodiment is that the first layer of filter material 11, the second layer of filter material 12, the third layer of filter material 13, The fourth layer of filter material 14 is a positively charged membrane, an activated carbon fiber membrane, an ion exchange fiber membrane and a positively charged membrane in sequence.

[0077] In this embodiment, the positively charged membrane has a smooth surface, is not easy to adhere to impurities, is easy to clean, and can also protect other filter materials between the two layers of positively charged membranes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com