Preparation method of rubber asphalt mastic crushed stone mixture

A technology for rubberized asphalt and mixture, applied in the field of asphalt mixture preparation, can solve the problems of difficult construction, no road standards or specifications, and high technical requirements, and achieves strong resistance to water damage, small voids, and strong resistance to load deformation. and the effect of high temperature rutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method for rubber asphalt mastic gravel mixture, comprising the following steps:

[0028] (1) Select radial tires or bias tires to remove the bezel part of waste tires, and crush them into 30 mesh rubber powder at room temperature;

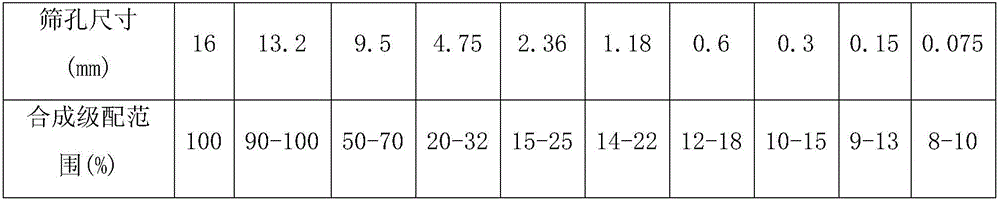

[0029] (2) Screen the aggregates used step by step from 0.075-16mm according to the full sieve holes, and use graded aggregates with the following gradation range for the aggregates:

[0030] Mesh size(mm)

16

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Synthetic grading range (%)

100

94

60

28

21

17

13

11

9

8

[0031] (3) Heat the asphalt to 140°C, raise the temperature to 175°C, and the heating rate is 10°C / h, and transport it to the batching tank through the flowmeter, and add rubber powder at the same time, the feeding time is 1min, and the temperature reaches 180°C and starts to stir for 5min. Then be transported to the storage tank for stirrin...

Embodiment 2

[0045] A preparation method for rubber asphalt mastic gravel mixture, comprising the following steps:

[0046] (1) Select radial tires or bias tires to remove the bezel part of waste tires, and crush them into 30 mesh rubber powder at room temperature;

[0047] (2) Screen the aggregates used step by step from 0.075-16mm according to the full sieve holes, and use graded aggregates with the following gradation range for the aggregates:

[0048] Mesh size(mm)

16

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Synthetic grading range (%)

100

94

59

27

21

18

15

13

11

9

[0049] (3) Heat the asphalt to 150°C, raise the temperature to 180°C, and the heating rate is 20°C / h, transport it to the batching tank through the flow meter, and add rubber powder at the same time, the feeding time is 1min, and the temperature reaches 180°C and starts to stir for 5min , and then transported to the storage tank for stirrin...

Embodiment 3

[0064] A preparation method for rubber asphalt mastic gravel mixture, comprising the following steps:

[0065] (1) Select radial tires or bias tires to remove the bezel part of waste tires, and crush them into 30 mesh rubber powder at room temperature;

[0066] (2) Screen the aggregates used step by step from 0.075-16mm according to the full sieve holes, and use graded aggregates with the following gradation range for the aggregates:

[0067] Mesh size(mm)

16

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Synthetic grading range (%)

100

96

61

28

22

20

16

14

12

10

[0068] (3) Heat the asphalt to 145°C, raise the temperature to 180°C, and the heating rate is 15°C / h, and transport it to the batching tank through the flowmeter, and add rubber powder at the same time, the feeding time is 1min, and the temperature reaches 190°C and starts to stir for 5min. Then be transported to the storage tank for stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com