Method for preparing inorganic ceramic membrane separation device from coal gangue

A technology for inorganic ceramic membranes and separation elements, applied in separation methods, semi-permeable membrane separations, ceramic products, etc., can solve the problems of high price and high cost of porous ceramic membrane separation elements, achieve rich raw material selection and preparation methods, and realize resources Effects of globalization and high value-added utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

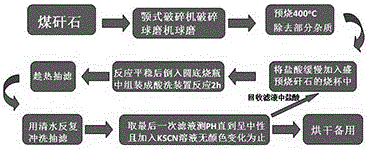

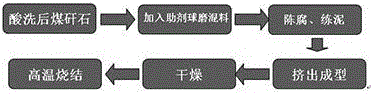

[0035] In the following, with reference to the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of a method for preparing inorganic ceramic membrane separation elements from coal gangue according to the present invention will be described in detail below.

[0036] see Figure 1-2 , a method of using coal gangue to prepare inorganic ceramic membrane separation elements. The raw materials used are mainly collected from multiple coal mines in Guizhou Province. They are crushed by jaw crushers, disc mills, etc., and analyzed by X-ray fluorescence spectroscopy. Finally, through multi-level and all-round comparative analysis, coal gangue from Yushe Coal Industry in Liupanshui City, Guizhou Province was selected as the raw material.

[0037] In order to effectively use coal gangue as a raw material for preparing porous ceramics, coal gangue must be pretreated. The literature shows that the use of high-concentration hydrochl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com