Trolley type gas preheating furnace

A gas preheating furnace, trolley-type technology, applied in heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of easy noise, low work efficiency, poor heat resistance, etc., and achieve high furnace temperature uniformity and work efficiency High, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

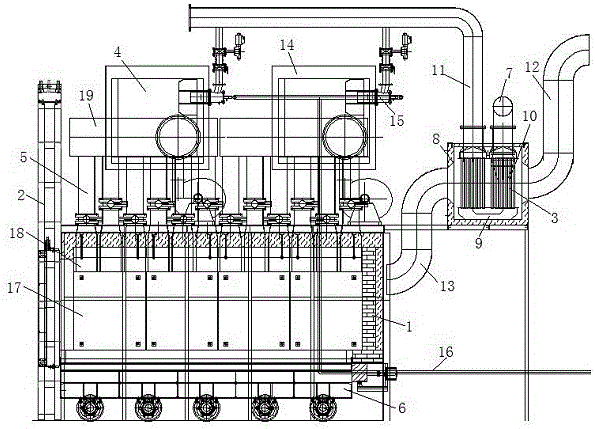

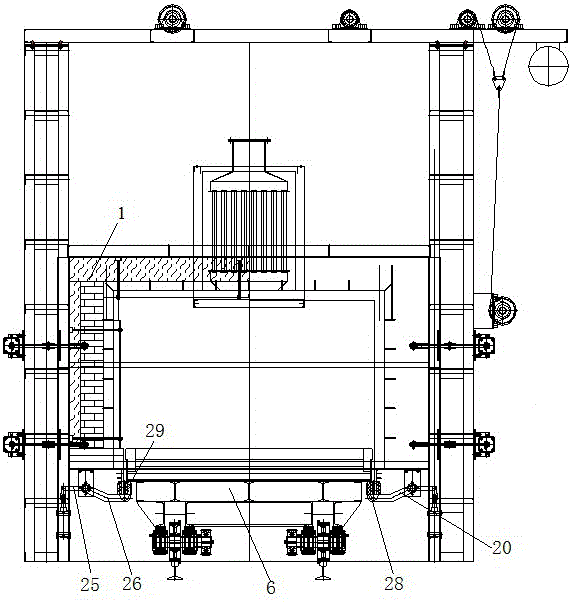

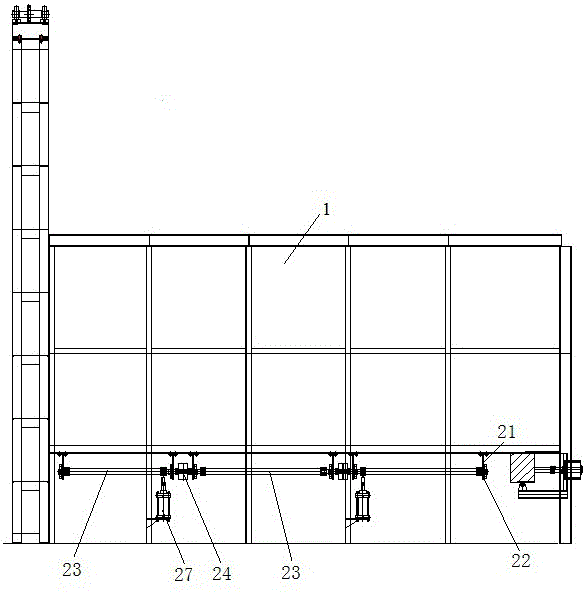

[0010] The specific content of the present invention is described in detail with reference to the accompanying drawings. Trolley type gas preheating furnace, including furnace body 1, furnace door 2, air preheating device 3, gas heating device 4 and temperature equalization device 5. The back side of furnace body 1 is provided with a lift type for sealing furnace body 1 The furnace door 2, the furnace body 1 is provided with a furnace lining, and the insulation fiber cotton is filled between the furnace lining and the inner wall of the furnace body 1. The lower part of the furnace body 1 is provided with a trolley device 6 that moves along the track, the trolley device 6 and the furnace body 1 is sealed by a compression device 20, the bottom of the two side walls of the furnace body 1 are respectively fixed with a synchronous rotating shaft 23 through a suspension rod 21 and a bearing 22, the synchronous rotating shaft 23 is formed by connecting a multi-section rotating shaft th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com