Ti2AlNb-based alloy fusion welding joint heat treatment process

A technology for fusion welding joints and post-weld heat treatment, which is applied in the field of heat treatment technology of Ti2AlNb-based alloy fusion welding joints, can solve the problems of poor plasticity at high temperature, comprehensive mechanical properties that do not meet engineering application, and uneven structure of welded joints. The effect of high temperature plasticity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. In the following description, for purposes of explanation and not limitation, specific details are set forth in order to provide a thorough understanding of the invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced in other embodiments that depart from these specific details.

[0014] The inventor has obtained the best embodiment of the present invention through repeated tests, earnest research, and repeated comparisons.

[0015] The inventor first studied the effect of post-weld aging heat treatment on the microstructure and properties of welded joints:

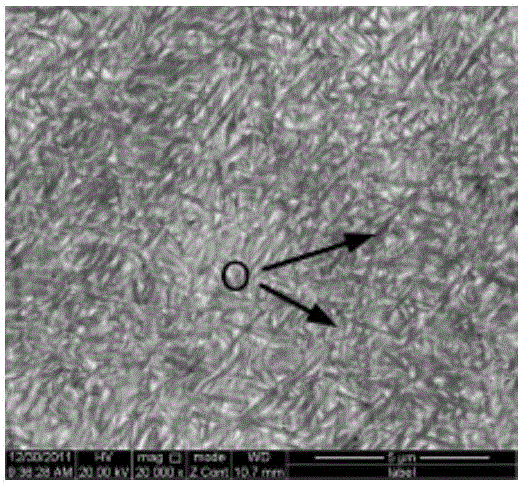

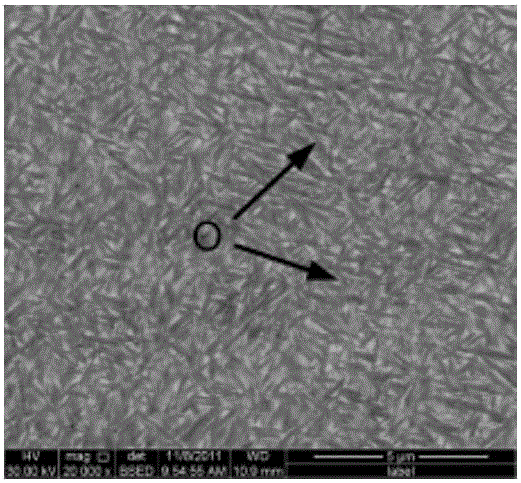

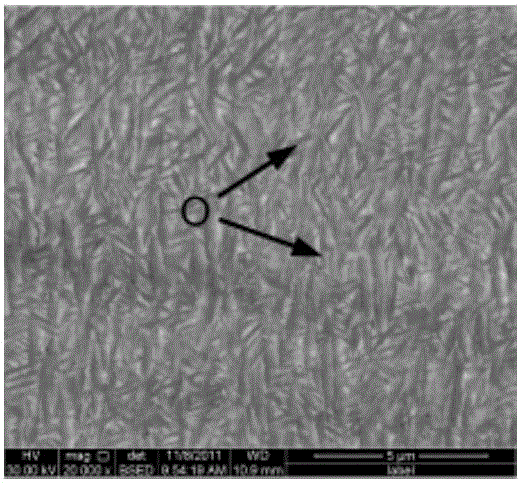

[0016] Since the Ti2AlNb alloy laser welded microstructure is a coarse B2 phase, the mechanical properties are poor, so post-weld heat treatment is required to improve the Ti2AlNb alloy welded microstructure. According to the stable ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com