Antibacterial finishing agent for apparel fabrics and finishing process thereof

An antibacterial finishing agent and technology of antibacterial finishing, applied in fiber processing, textiles and papermaking, etc., can solve the problems of poor durability and reusability, prone to wrinkles, affecting the beauty of people's wearing, etc., to achieve good durability and repeated use. properties, preventing the spread of microorganisms, and the effect of good wrinkle resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

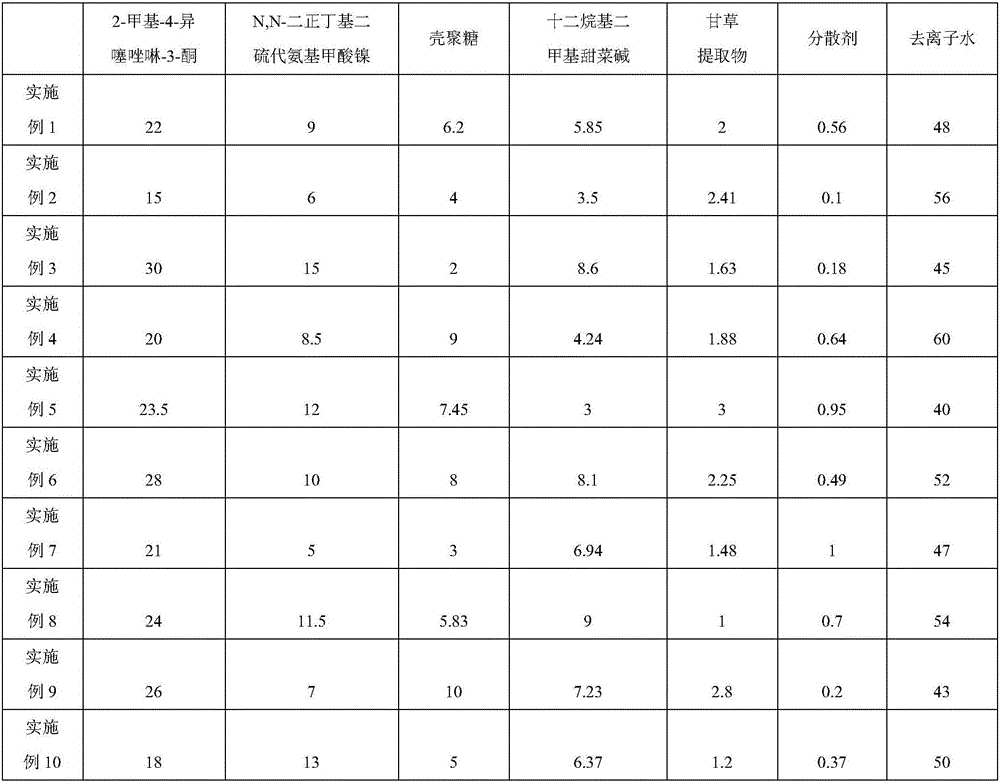

Examples

Embodiment 1

[0043] (1) heating the antibacterial finishing agent of the clothing fabric to 55°C;

[0044] (2) Soak the clothing fabric in the antibacterial finishing agent for finishing, and the finishing time is: 25 minutes;

[0045] (3) After taking out the clothing fabric, rinse it with 2°C cooling water and dry it.

Embodiment 2

[0047] (1) heating the antibacterial finishing agent of the clothing fabric to 45°C;

[0048] (2) Soak the clothing fabric in the antibacterial finishing agent for finishing, and the finishing time is: 35 minutes;

[0049] (3) Rinse the clothing fabric with cooling water at 0°C after taking it out, and dry it.

Embodiment 3

[0051] (1) heating the antibacterial finishing agent of the clothing fabric to 50°C;

[0052] (2) Soak the clothing fabric in the antibacterial finishing agent for finishing, and the finishing time is: 20 minutes;

[0053] (3) Rinse the fabric with 5°C cooling water after taking it out, and dry it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com