Segmental Assembled Beam Prestressed Tunnel Connector

A prestressed and connector technology, used in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of air leakage and slurry leakage, affecting the durability of prestressed steel bundles, and extrusion of colloid into the pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

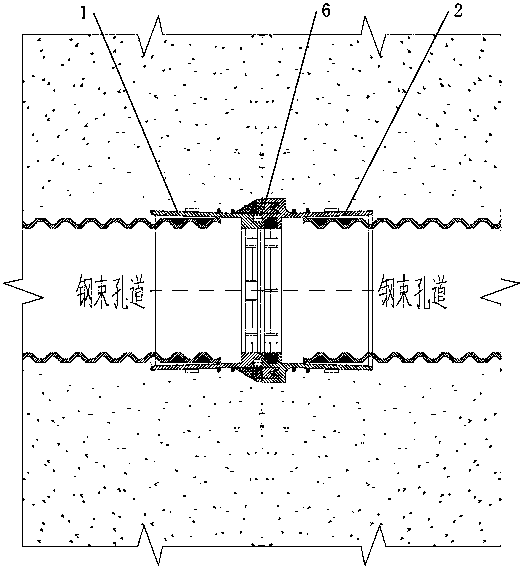

[0044] A segmental assembled beam prestressed tunnel connector, comprising a matching section casing 1, a cast-in-place section casing 2, a one-way plug 3, a two-way plug 4, an inner snap ring 5 and a sealing ring 6.

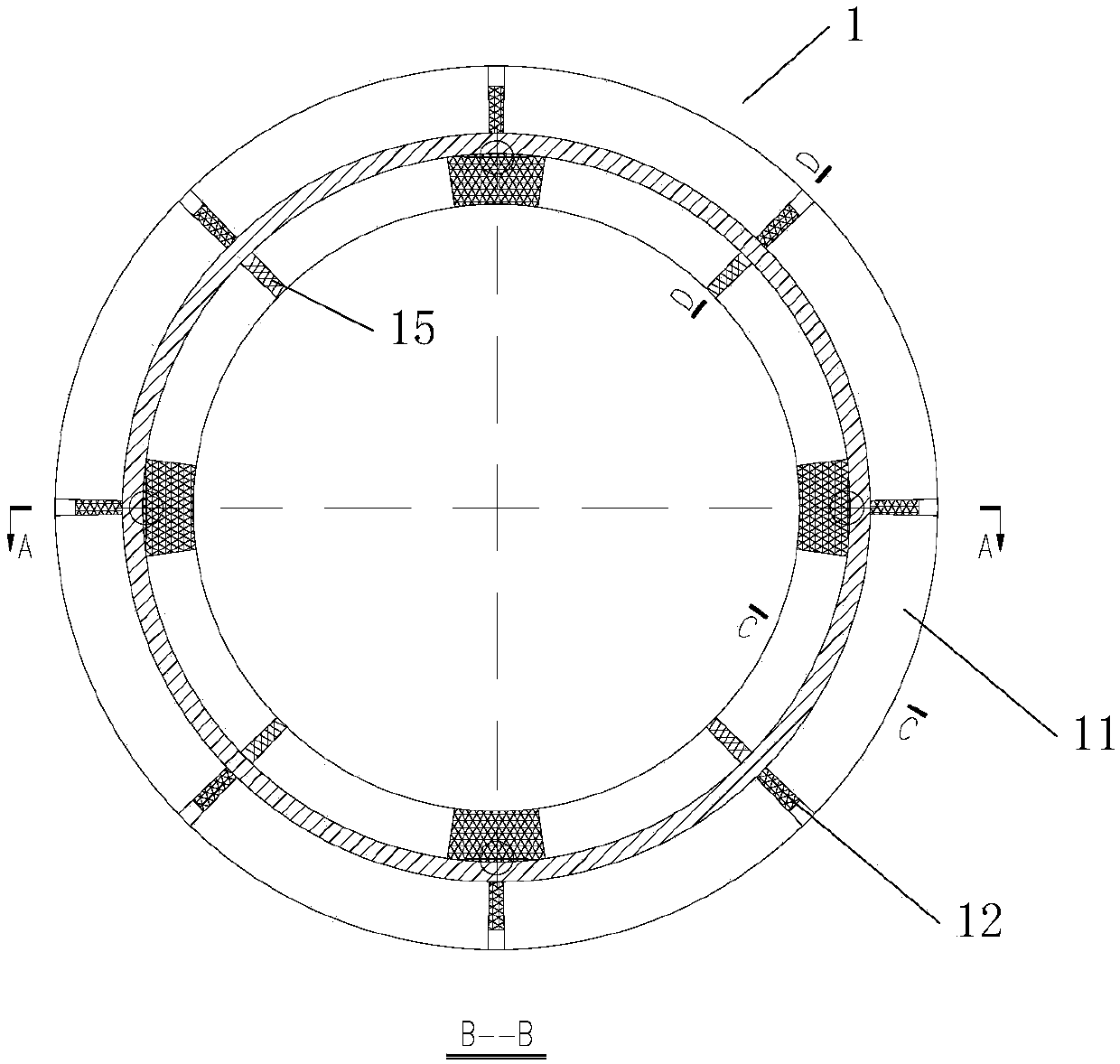

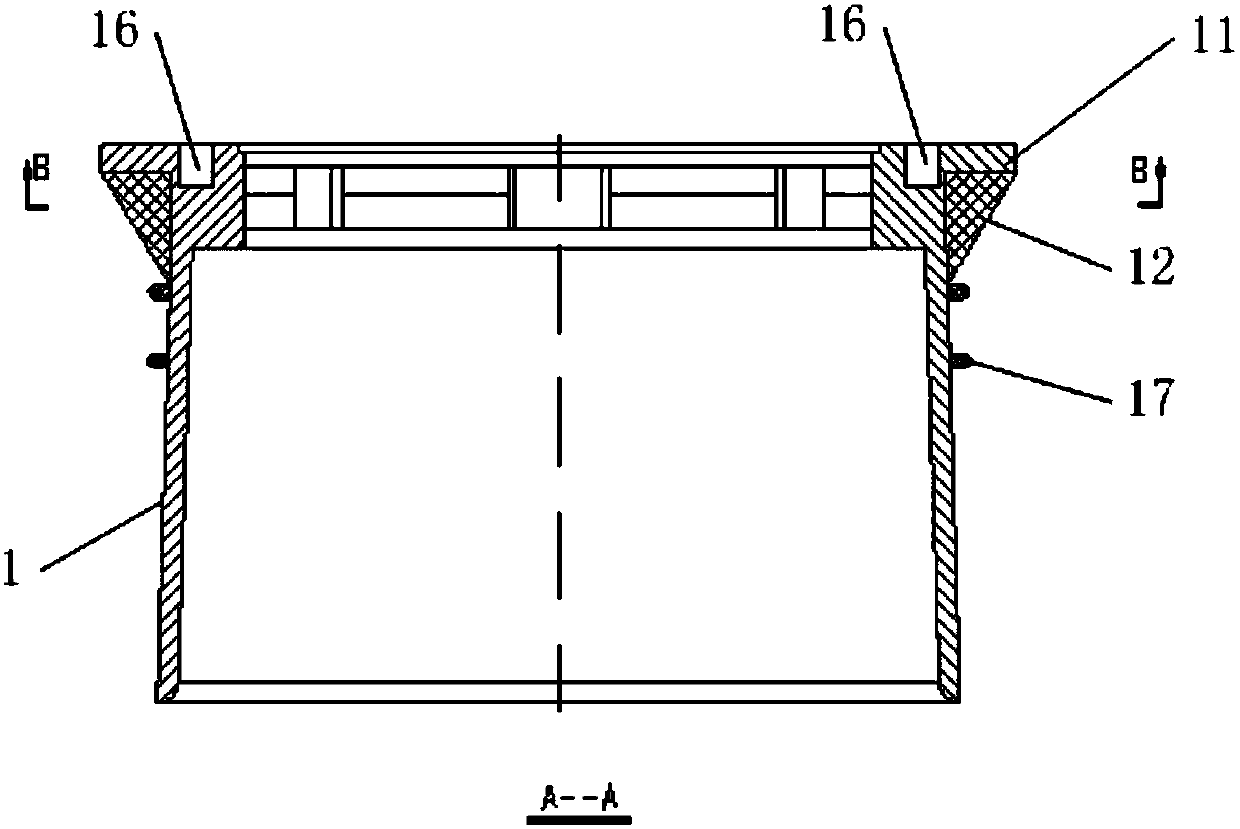

[0045] Such as Figure 1-5 As shown, the shape of the matching section casing 1 is generally bell-shaped, and an annular flange 11 is integrally formed radially on the outer wall of the smaller diameter end, and the distance between the annular flange 11 and the outer wall is evenly spaced. Eight reinforcin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com